Understanding the Critical Role of Forklift Bearings

Forklift bearings are the unsung heroes of material handling operations, functioning as precision components that facilitate smooth rotational or linear movement while reducing friction and handling stress. These components are fundamental to the performance, safety, and longevity of virtually every moving part in a forklift, from the mast assembly and drive wheels to the steering mechanism and hydraulic pumps. Operating in some of the most demanding industrial environments, they are subjected to extreme loads, shock impacts, constant vibrations, and exposure to contaminants. A failure in a single bearing can lead to catastrophic downtime, expensive repairs, and even pose significant safety risks to operators and nearby personnel. Therefore, possessing a comprehensive understanding of the different types of bearings, their specific applications, and proper maintenance protocols is not merely a technical nicety—it is an operational and economic necessity for any business that relies on forklifts for its daily logistics and warehousing activities. This guide delves deep into the world of forklift bearings, providing the essential knowledge needed to make informed decisions, optimize performance, and ensure maximum equipment uptime.

Why Proper Bearing Selection is Non-Negotiable

Selecting the correct bearing for a specific application within a forklift is a complex decision that hinges on a multitude of factors. It is far more than just matching a part number; it involves a careful analysis of the operating conditions, load characteristics, and performance requirements.

Key Factors Influencing Bearing Choice

The process of selecting the right bearing requires a systematic approach. Consider the following critical parameters:

- Load Type and Magnitude: Bearings are designed to handle different types of loads: radial (perpendicular to the shaft), axial (parallel to the shaft), or a combination of both. The magnitude of the load, including both typical operating weight and potential peak shock loads, determines the required load capacity and size of the bearing.

- Rotational Speed: The operational speed of the application influences the choice of bearing type, cage design, and lubrication method. High-speed applications may require precision bearings with special lubricants to manage heat generation.

- Environmental Conditions: Exposure to dust, moisture, chemicals, extreme temperatures, and other contaminants dictates the necessity for sealed or shielded bearings and can influence the choice of material (e.g., stainless steel for corrosion resistance).

- Precision and Tolerance Requirements: Applications like steering systems demand high precision and minimal play for accurate control, necessitating bearings manufactured to tighter tolerance classes.

- Installation and Maintenance Constraints: The design of the surrounding components may favor a specific bearing type, such as a pillow block for easy mounting or a cartridge unit for simplified replacement.

Common Bearing Types and Their Forklift Applications

Different parts of a forklift utilize different bearing types, each engineered for a specific purpose. Understanding these types is the first step toward effective maintenance and troubleshooting.

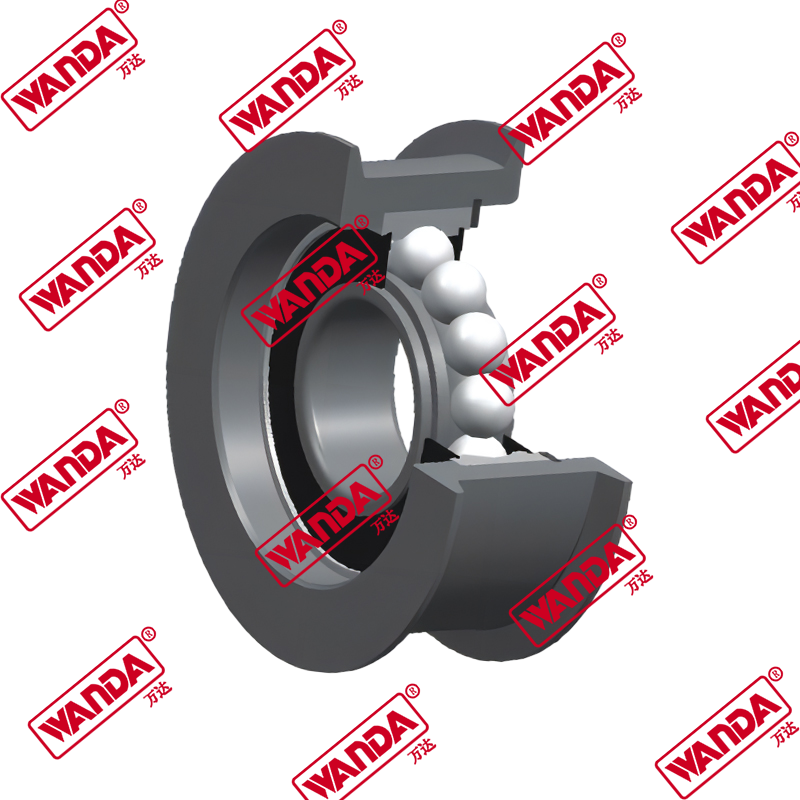

Ball Bearings

Ball bearings are among the most common types, using spherical balls to maintain separation between the bearing races. They are primarily designed to handle radial loads but can support moderate axial loads in one or both directions, depending on their design (e.g., deep groove, angular contact).

- Typical Applications: Electric motor shafts, idler pulleys, and various auxiliary equipment where speeds are high and loads are relatively light to moderate.

- Advantages: Low friction, capable of high speeds, relatively low cost, and available in a wide variety of sizes and configurations.

- Limitations: Can be damaged by shock loads and are not ideal for very heavy radial loads compared to other types.

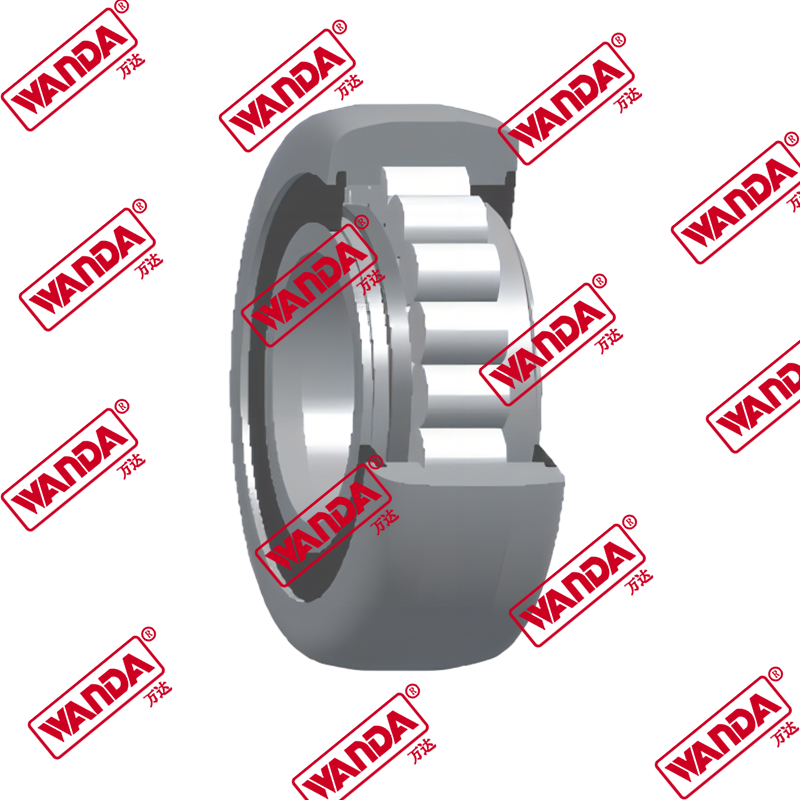

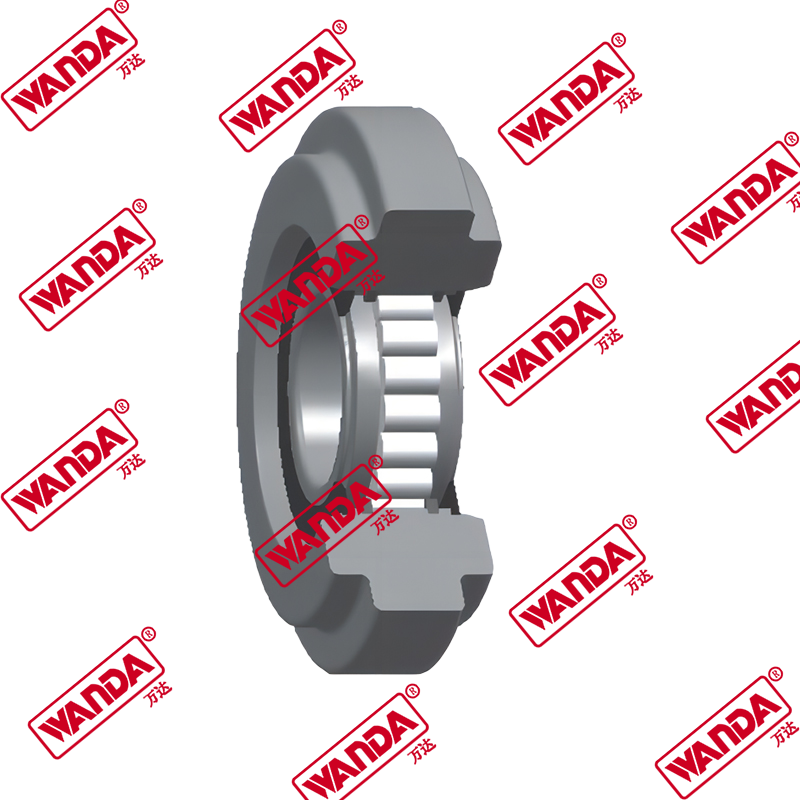

Roller Bearings

Roller bearings use cylindrical, spherical, or tapered rollers instead of balls. This design provides a much larger contact area with the races, allowing them to support significantly heavier loads than ball bearings of the same size.

- Typical Applications: Mast rollers, wheel hubs, and other high-load points on a forklift where shock and radial loads are extreme.

- Advantages: High radial load capacity, robust construction, and better shock load resistance.

- Limitations: Generally have higher friction and are limited in their maximum speed capabilities compared to ball bearings.

The following table provides a concise comparison between these two primary bearing types in a forklift context:

| Parameter | Ball Bearings | Roller Bearings |

|---|---|---|

| Primary Load Type | Radial & Moderate Axial | Very Heavy Radial |

| Contact Area | Point Contact | Line Contact |

| Load Capacity (Size-for-Size) | Moderate | High |

| Speed Capability | High | Moderate |

| Shock Load Resistance | Low to Moderate | High |

| Typical Cost | Generally Lower | Generally Higher |

Essential Maintenance for Maximum Forklift Bearing Life

Proactive and preventative maintenance is the single most effective strategy for maximizing the service life of forklift bearings and avoiding unexpected failures. A comprehensive maintenance regimen revolves around three core principles: proper lubrication, effective contamination control, and consistent monitoring.

The Lifeline: Proper Lubrication Techniques

Lubrication serves multiple critical functions: it reduces friction between rolling elements and races, dissipates heat, protects against corrosion, and helps seal out contaminants. Using the wrong lubricant or incorrect amount is a leading cause of premature bearing failure.

Choosing the Right Lubricant

The selection of a lubricant—whether grease or oil—depends on the bearing's operating speed, temperature, and load. Grease is the most common choice for forklift applications due to its ease of retention and inherent sealing properties.

- Grease Consistency (NLGI Grade): A grade that is too hard will not flow to protect the bearing, while a grade that is too soft may leak out. Most industrial bearings use NLGI Grade 2 grease.

- Base Oil Viscosity: The viscosity of the oil within the grease must be suitable for the operating temperature and speed to maintain a protective film.

- Additives: Look for greases with anti-wear (AW), extreme pressure (EP), and rust-inhibiting additives to handle the demanding conditions of a forklift's operation.

Establishing a Lubrication Schedule

Adhering to a manufacturer-recommended lubrication schedule is paramount. Over-lubrication can be as detrimental as under-lubrication, as it can cause excessive heat build-up due to churning in high-speed applications. The schedule should be adjusted based on the severity of service: forklifts operating in hot, dusty, or multi-shift environments will require more frequent lubrication.

Identifying and Addressing Common Bearing Failures

Recognizing the early signs of bearing wear or failure allows for planned intervention before a minor issue escalates into a major breakdown. Common failure modes include fatigue spalling, abrasive wear, adhesive wear (smearing), corrosion, and catastrophic fracture.

Symptoms and Root Causes

Operators and maintenance personnel should be trained to identify the warning signs:

- Unusual Noises: A grinding, rumbling, or screeching sound often indicates a lack of lubrication, contamination, or advanced wear.

- Excessive Vibration: Increased vibration can signal brinelling (indentations from shock loads), misalignment, or uneven wear.

- Increased Operating Temperature: A bearing that is hot to the touch is likely suffering from over-lubrication, under-lubrication, or excessive load.

- Irregular Operation: Rough movement, sticking, or increased play in the mast or steering can point directly to bearing issues.

Understanding the difference between a symptom and a root cause is essential. For example, replacing a noisy bearing without addressing the faulty seal that allowed grit to enter will only lead to a repeat failure. This is where a thorough understanding of forklift mast bearing replacement procedures becomes critical, as it involves not just swapping a part but ensuring the entire assembly is clean, aligned, and properly sealed.

Navigating the World of Forklift Bearing Specifications

Selecting a replacement bearing requires navigating a complex landscape of specifications, standards, and numbering systems. Using an incorrect or substandard bearing can compromise performance and safety.

Interpreting Bearing Codes and Sizes

Bearings are identified by standardized numbering systems that encode their type, dimensions, and sometimes their tolerance class. The most common system is the ABEC scale, but it's crucial to understand that this primarily defines tolerances and not necessarily quality or durability in high-load industrial contexts.

Beyond the Part Number: Critical Dimensions

The three most critical dimensions for any bearing are the bore diameter (inside diameter), the outer diameter (OD), and the width. These must be measured precisely to ensure a correct fit. Furthermore, specifications like radial internal clearance (C3 is common for industrial applications to accommodate thermal expansion) and dynamic/static load ratings must be consulted to ensure the bearing is suited for the application's demands.

Material Science: What Are Your Bearings Made Of?

The vast majority of bearings are made from high-carbon chromium steel (e.g., SAE 52100), which offers an excellent balance of hardness, toughness, and fatigue resistance. However, for specialized applications, other materials are available.

- Stainless Steel (e.g., 440C): Used in applications where corrosion resistance is a primary concern, such as in food processing, chemical, or marine environments. It's important to note that corrosion resistant forklift bearings may have slightly lower load ratings than their chrome steel counterparts.

- Plastic or Polymer Bearings: Made from materials like PEEK or nylon, these are used in applications where lubrication is impossible or where extreme chemical resistance is needed.

- Ceramic Bearings: Utilizing silicon nitride balls, these hybrid bearings offer superior speed capabilities, reduced weight, and electrical insulation, but at a significantly higher cost.

When considering a high capacity forklift bearing, the material and its heat treatment are paramount. These bearings are often manufactured through processes like case carburizing, which creates a hard, wear-resistant outer surface while maintaining a tougher, more ductile core to withstand shock loads.

A Practical Guide to Forklift Bearing Replacement

Replacing a forklift bearing is a precise task that requires the right tools, techniques, and safety precautions. Rushing the job or using improper methods can damage the new bearing and the components it fits into.

Step-by-Step Removal and Installation

A systematic approach ensures a successful and long-lasting repair.

Safe Removal of the Worn Bearing

The goal is to remove the old bearing without damaging the shaft or housing.

- Documentation and Cleanliness: Before disassembly, take photos and notes of the orientation and arrangement of parts. Clean the external area thoroughly to prevent dirt from entering the system.

- Use the Right Tools: Always use dedicated bearing pullers (mechanical, hydraulic, or hydraulic) rather than hammers and chisels, which can damage shafts and create safety hazards. Applying heat to the inner race with an induction heater can greatly ease removal by expanding the metal, a key technique for forklift bearing installation tips.

Precision Installation of the New Bearing

Installation is even more critical than removal. The force for installation must be applied evenly and correctly.

- Preparing the New Bearing: Unless specified otherwise, bearings should be installed clean and dry. The lubricant included by the manufacturer is usually sufficient for initial operation.

- Applying Force Correctly: The installation force must be applied to the race that has the interference fit. For a bearing pressed onto a shaft, force should be applied to the inner ring. For a bearing pressed into a housing, force should be applied to the outer ring. Using the wrong race will damage the bearing's internal surfaces.

- Using Drivers and Arbors: Use a socket or tubular driver that matches the diameter of the race being pressed. Never strike the bearing directly. For large bearings, using an arbor press is the preferred method.

Adhering to these forklift bearing installation tips is non-negotiable for a reliable repair. Furthermore, for critical components like the drive unit, understanding the specific procedure for a forklift drive wheel bearing replacement is essential, as it often involves setting precise pre-loads on tapered roller bearings to ensure proper wheel alignment and longevity.

Post-Installation Checks and Run-In

The job is not complete once the bearing is installed. A series of checks must be performed:

- Visual Inspection: Ensure the bearing is seated completely and squarely against its shoulder.

- Rotation Check: Manually rotate the bearing or the assembly. It should turn smoothly and freely without any binding or grating sensations.

- Operational Test: Run the equipment at low speed without load and listen for any unusual noises. Monitor the temperature for the first hour of operation to ensure it stabilizes at a normal level.

Enhancing Performance with Advanced Bearing Solutions

The bearing industry is continuously innovating, developing new solutions to push the boundaries of performance, efficiency, and durability. For operations looking to optimize their fleet, exploring these advanced options can yield significant benefits.

Sealed and Lubricated-for-Life Units

These bearings are pre-packed with high-quality grease and fitted with high-efficiency seals or shields. They are designed to operate for their entire service life without requiring relubrication, eliminating a maintenance task and reducing the risk of contamination during grease fitting. They are ideal for applications where relubrication is difficult or impossible.

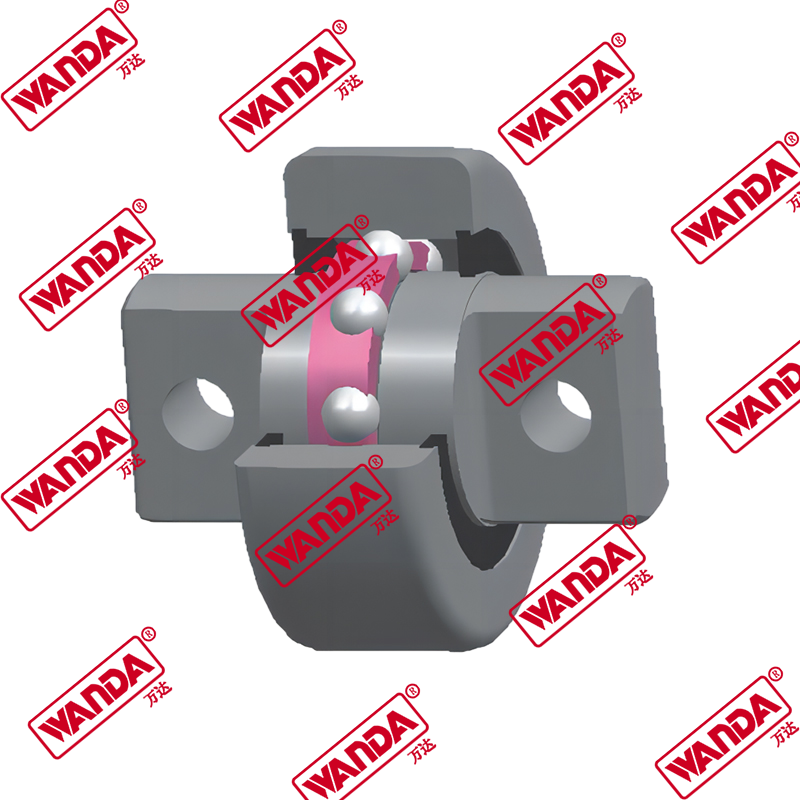

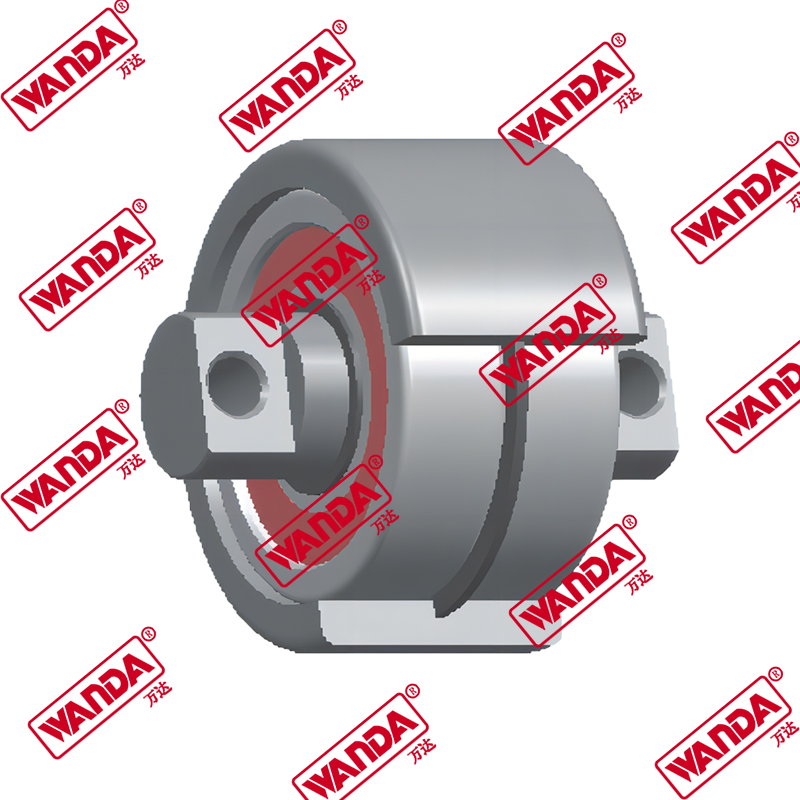

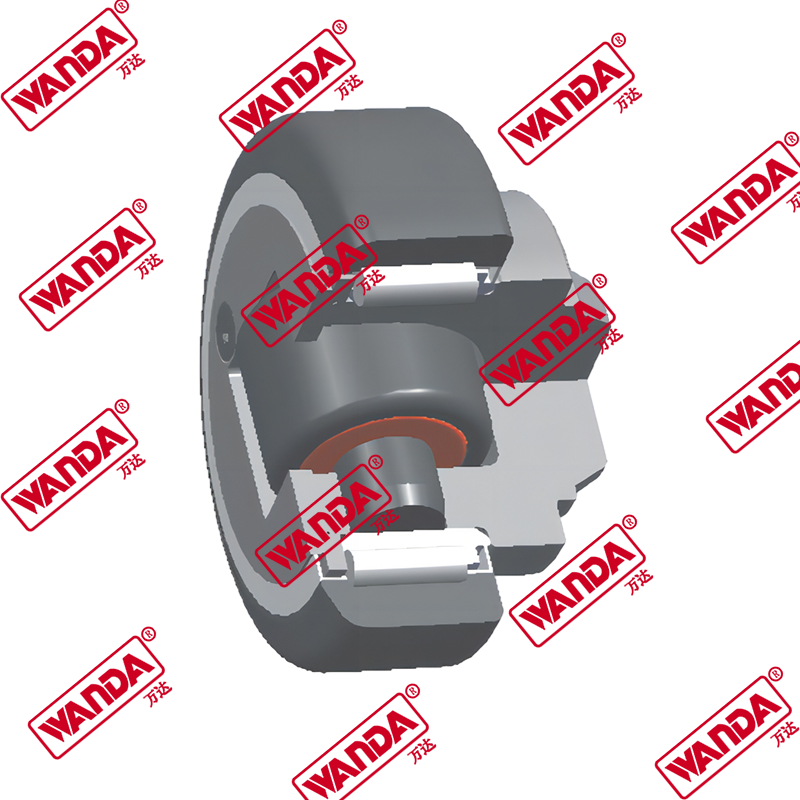

Integrated Bearing Units

These are complete, ready-to-mount assemblies that consist of a bearing housed within a precision-machined casting or forging, often with seals and pre-lubrication. Common types include pillow blocks, flange blocks, and take-up units. They simplify installation, ensure perfect alignment, and protect the bearing from environmental hazards, making them a robust solution for many forklift applications.

The Future: Smart Bearings and Condition Monitoring

The next frontier in bearing technology involves embedding sensors directly into bearing units. These "smart bearings" can continuously monitor their own operating conditions—including temperature, vibration, and load—and transmit this data to a central maintenance system. This enables a shift from preventative maintenance to predictive maintenance, where repairs are scheduled precisely when needed, maximizing uptime and resource allocation.

In conclusion, while often overlooked, forklift bearings are fundamental to safe and efficient operation. A strategic approach to their selection, maintenance, and replacement, informed by a deep understanding of their function and requirements, is a powerful tool for any operation seeking to minimize costs and maximize productivity.