Understanding the Critical Role of Forklift Wheel Chains

Within the intricate ecosystem of material handling equipment, the forklift stands as a pillar of industrial and warehouse operations. While engines, masts, and forks often receive the most attention, the drive system, particularly the wheel chains, is a fundamental component that ensures smooth and powerful movement. A forklift wheel chain is not merely an accessory but the critical link that transmits power from the drive motor to the wheels, enabling the forklift to carry immense loads with precision and stability. Understanding the nuances of this component is essential for any operation seeking to maximize efficiency, minimize downtime, and ensure operator safety. This guide delves deep into the world of forklift wheel chains, providing a comprehensive resource for selection, maintenance, and troubleshooting, focusing on key aspects such as heavy duty forklift chain specifications and the signs indicating a necessary forklift drive wheel replacement.

The consequences of neglecting this vital component can be severe. A failed chain can lead to catastrophic operational halt, potential damage to goods and equipment, and even pose significant safety risks. Therefore, a proactive approach to chain management is not just recommended but required. This section establishes the importance of the wheel chain by exploring its function, the different types available, and the direct impact its condition has on overall forklift performance. We will explore how the right chain selection influences load capacity, maneuverability, and the long-term health of the drive train components.

What is a Forklift Wheel Chain?

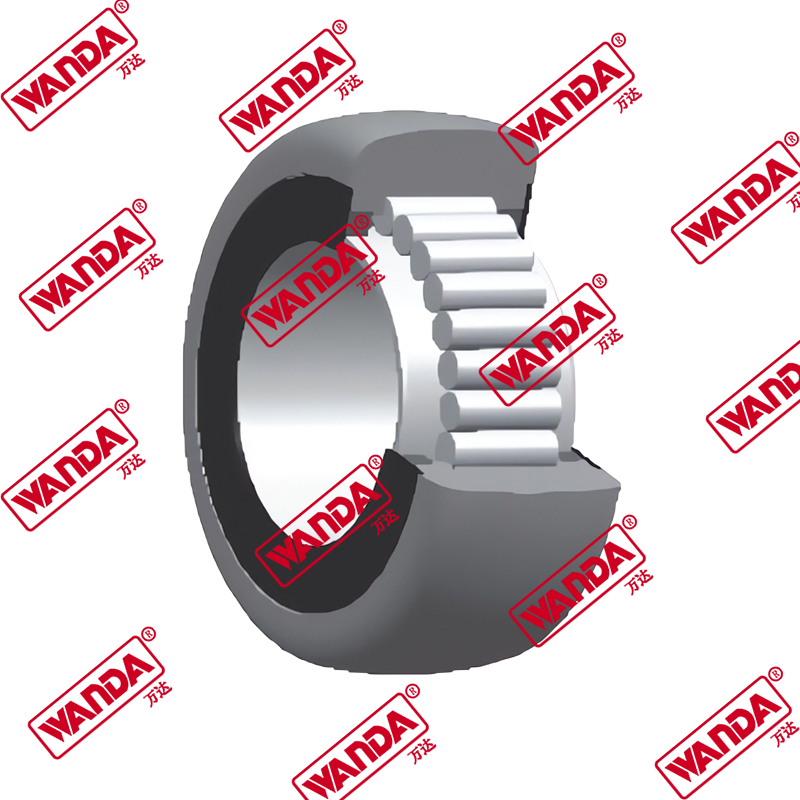

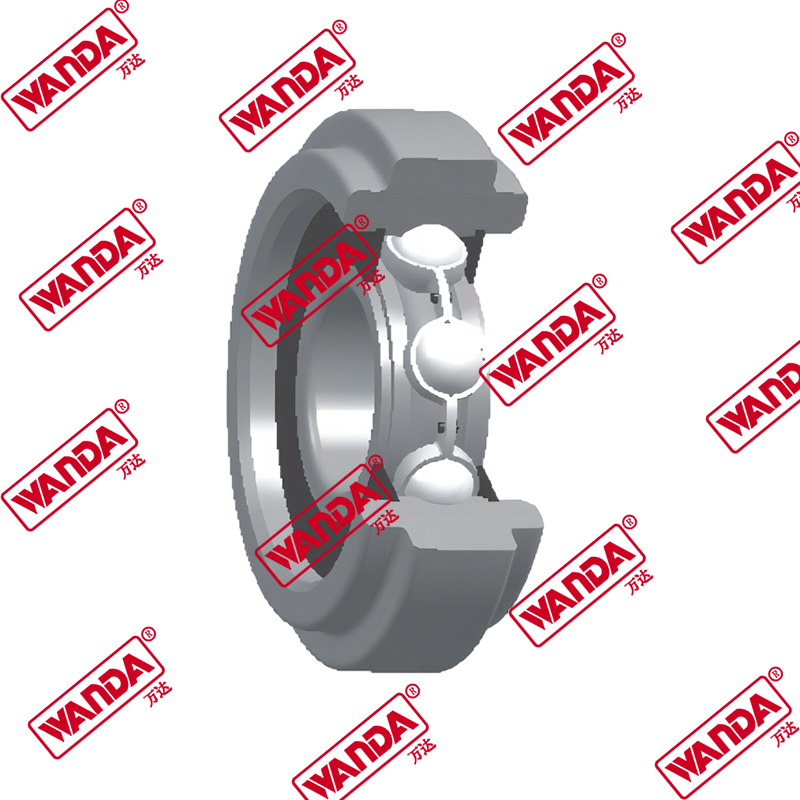

A forklift wheel chain is a specially engineered roller chain designed to handle high torque, heavy loads, and the demanding stop-start cycles typical of material handling applications. Unlike standard bicycle chains, these are manufactured to exacting heavy duty forklift chain specifications, which include specific tensile strength, hardness, and fatigue resistance metrics. They are typically constructed from alloy steel and undergo heat treatment processes to achieve the necessary durability. The chain rides on sprockets that are either connected to the drive motor or directly to the wheel hub, creating a reliable and efficient power transmission system.

The design incorporates precise pin and bushing tolerances to ensure smooth engagement with the sprocket teeth while minimizing wear. Proper lubrication is integrated into the design, with many systems featuring automatic oilers or sealed environments to reduce maintenance frequency. Understanding this basic construction is the first step in appreciating why specific chains are required for specific applications and why a one-size-fits-all approach can lead to premature failure and operational inefficiencies.

Primary Functions and Operational Importance

- Power Transmission: The core function is to transfer rotational force from the power source to the drive wheels, propelling the forklift forward and backward.

- Load Handling Capacity: The chain's strength directly correlates to the forklift's ability to lift and move heavy loads without slippage or failure.

- Operational Stability: A well-maintained chain ensures smooth acceleration and deceleration, preventing jerky movements that could destabilize a load.

- Safety Assurance: Integrity of the chain is paramount; a failure during operation can lead to loss of control, making it a critical safety component.

- Energy Efficiency: A correctly tensioned and lubricated chain reduces friction and power loss, contributing to better battery life in electric models or fuel efficiency in internal combustion engines.

Selecting the Right Chain for Your Forklift

Choosing an appropriate wheel chain is a decision that impacts performance, safety, and total cost of ownership. It is not a generic component, and selection must be based on a careful assessment of several factors. The process involves understanding your forklift's model specifications, the typical operating environment, and the load requirements. A common mistake is opting for a chain based solely on price, which often leads to more frequent forklift drive wheel replacement cycles and increased downtime. This section will guide you through the critical parameters to consider, ensuring you select a chain that offers reliability and longevity.

The operating environment plays a crucial role. For instance, forklifts used in cold storage facilities require chains with lubricants that won't solidify at low temperatures, while those in corrosive environments (e.g., chemical plants or seafood processing) might need chains with specific protective coatings. Similarly, the intensity of use—single-shift versus multi-shift operations—will dictate the required quality and durability of the chain. Ignoring these factors can quickly lead to premature wear, chain stretch, and ultimately, a need for a complete drive axle sprocket repair due to accelerated sprocket wear from an ill-fitting or poor-quality chain.

Key Selection Criteria

When evaluating different chains, you must cross-reference the manufacturer's specifications with your operational needs. The following table outlines the primary criteria for selection and provides a comparative overview to aid in decision-making.

It is crucial to match the chain's tensile strength to the forklift's maximum load capacity. A chain with insufficient strength will stretch under load, leading to poor performance and potential failure. Furthermore, the pitch and width of the chain must perfectly match the sprockets on both the drive motor and the wheel hub. Using an incorrect size will cause improper meshing, rapid wear on both the chain and the sprocket, and generate excessive noise. This misalignment is a primary reason for unexpected forklift drive wheel replacement and subsequent drive axle sprocket repair.

Comparison of Chain Types Based on Application

| Selection Criteria | Standard Duty Application | Heavy Duty Application | Severe/Corrosive Environment |

|---|---|---|---|

| Tensile Strength | Medium grade, suitable for loads below 70% of max capacity | Very high grade, designed for loads at or near 100% max capacity | High grade, with strength maintained despite protective coatings |

| Material & Coating | Standard carbon steel, minimal coating | Alloy steel, through-hardened | Stainless steel or carbon steel with nickel or zinc plating |

| Lubrication Requirement | Regular manual lubrication | Frequent lubrication or automated systems | Specialty lubricants for low temp or high moisture |

| Ideal Use Case | Warehousing, light indoor use, single-shift operations | Ports, lumber yards, steel handling, multi-shift operations | Food processing, cold storage, chemical plants, marine applications |

Comprehensive Maintenance and Lubrication Protocols

Regular and precise maintenance is the most effective strategy to extend the service life of your forklift wheel chains and avoid costly repairs. A neglected chain will inevitably lead to a forklift drive wheel replacement or a more extensive and expensive drive axle sprocket repair. A proactive maintenance routine focuses on three pillars: inspection, cleaning, and lubrication. This systematic approach allows for the early detection of issues like wear, elongation, and corrosion before they escalate into major failures. Establishing a scheduled maintenance log is highly recommended to track the condition of the chain over time and predict its remaining useful life.

The frequency of maintenance is not arbitrary; it should be dictated by the operational intensity and environment. A forklift operating in a clean, dry warehouse might require lubrication only once a week, while one working in a dusty, abrasive environment might need attention at the end of every shift. The goal of lubrication is to form a protective film between the chain's internal components (pins, bushings, and rollers) to minimize metal-on-metal contact and wear. However, over-lubrication can be just as detrimental as under-lubrication, attracting dirt and grime that act as abrasives. Understanding the best lubrication practice for forklift chains is, therefore, a balance between quantity, frequency, and using the correct type of lubricant.

Step-by-Step Maintenance Checklist

Implementing a consistent checklist ensures no critical step is missed during maintenance. The following procedure should be performed by a trained technician following all appropriate safety protocols, including de-energizing the equipment.

- Visual Inspection: Look for obvious signs of damage such as cracked links, bent side plates, or severe rust.

- Chain Tension Check: Measure the deflection at a specific point. Excessive tightness causes wear on sprockets and bearings; excessive looseness leads to slippage and jerky movement.

- Wear Measurement (Elongation Check): This is the most accurate way to assess chain health. Measure a set number of links and compare the length to the original specification. Elongation beyond 3% often indicates the need for replacement.

- Sprocket Inspection: Always inspect the sprockets when checking the chain. Worn or hooked sprocket teeth will destroy a new chain very quickly. Plan for a drive axle sprocket repair if any issues are found.

- Cleaning: Use a brush and a recommended solvent to remove old lubricant, dirt, and debris. Ensure the chain is completely dry before applying new lubricant.

- Lubrication: Apply the manufacturer-recommended lubricant evenly across the chain while slowly turning the wheels to ensure penetration into the internal joints.

Identifying Common Problems and Implementing Effective Solutions

Even with a robust maintenance program, issues can arise. Recognizing the early warning signs of chain problems is crucial for preventing operational downtime and avoiding more extensive damage to the drive system. Common symptoms include unusual noises (clicking, grinding, or squealing), jerky movement, visible wear on the chain or sprockets, and the presence of metal shavings in the chain case. These signs often point towards specific underlying issues that need immediate attention. A systematic approach to troubleshooting allows for quick diagnosis and rectification, ensuring the forklift returns to service quickly and safely.

Many chain problems are interrelated. For example, a frequently overlooked issue is how to adjust forklight chain tension correctly. Incorrect tension is a root cause of numerous other failures. A chain that is too tight places excessive stress on the chain itself, the sprockets, and the drive shaft bearings, leading to premature wear on all components. Conversely, a chain that is too loose can jump off the sprocket, causing severe damage to the chain, sprocket, and potentially the chain case. This section provides a diagnostic framework to identify common problems and their respective solutions, helping you decide whether a simple adjustment or a full forklift drive wheel replacement is necessary.

Troubleshooting Guide for Forklift Wheel Chains

The following guide outlines common problems, their potential causes, and recommended corrective actions. This structured approach helps in pinpointing the issue accurately.

Problem: Rapid Chain Wear or Elongation

- Cause: Inadequate or incorrect lubrication, leading to excessive friction.

- Cause: Operating in an abrasive environment without frequent cleaning.

- Cause: Misalignment of the drive and wheel sprockets.

- Solution: Review and implement the best lubrication practice for forklift chains. Ensure the correct type and amount of lubricant is applied at proper intervals.

- Solution: Increase the frequency of cleaning for harsh environments. Consider installing protective covers if feasible.

- Solution: Check sprocket alignment with precision tools. Realign components as necessary, which may require professional drive axle sprocket repair.

Problem: Chain Frequently Derails or Jumps

- Cause: Incorrect chain tension, either too loose or too tight.

- Cause: Worn-out sprocket teeth that no longer mesh properly with the chain.

- Cause: A stretched (elongated) chain that does not fit the sprocket pitch correctly.

- Solution: Learn how to adjust forklight chain tension according to the manufacturer's specified procedure and deflection tolerance.

- Solution: Inspect sprockets for wear. Replace the chain and sprockets as a set if the sprockets are worn; replacing only the chain will cause the new chain to wear rapidly.

Advanced Considerations for Peak Performance and Longevity

Beyond basic selection and maintenance, several advanced considerations can further optimize the performance and lifespan of your forklift's drive system. One critical area is the interaction between the chain and all other components in the drive train. For instance, when performing a forklift drive wheel replacement, it is a best practice to simultaneously inspect and often replace the chain and sprockets. This ensures that all components are in a like-new state of wear, preventing the old, worn sprocket from prematurely destroying the new chain, or vice-versa. This systems-thinking approach, though involving a higher initial parts cost, reduces total downtime and labor costs in the long run.

Another advanced concept is the analysis of failure modes. Conducting a root cause analysis on a failed chain can reveal deeper operational issues. For example, consistent failures on a specific forklift might point to an operator habit, such as aggressive shifting or constant impact with dock plates, that is placing abnormal stress on the drive system. Addressing these operational patterns through training can be more effective than repeatedly replacing parts. Furthermore, investing in training for maintenance staff on the precise techniques for how to adjust forklight chain tension and other procedures ensures that maintenance is always performed correctly, safeguarding your investment in both parts and labor.

Implementing a Predictive Maintenance Program

Moving from preventive (time-based) maintenance to predictive (condition-based) maintenance represents the pinnacle of operational optimization. This involves using data and regular condition monitoring to determine the actual state of the chain and perform maintenance only when needed.

- Regular Elongation Measurements: Track chain elongation over time to predict its end-of-life accurately and plan replacements during scheduled downtime, avoiding unexpected failures.

- Oil Analysis: For chains lubricated in an oil bath, periodic analysis of the oil can detect the presence of metal particles, indicating internal wear before it becomes visible.

- Thermographic Imaging: Using an infrared camera to scan the chain case can identify overheating in specific sections, often caused by a tight spot or a failing component.

- Acoustic Monitoring: Listening for changes in the sound profile of the drive system can provide an early warning of misalignment, insufficient lubrication, or the onset of wear.

Adopting these advanced practices transforms the management of your forklift wheel chain from a reactive cost center into a proactive strategy for enhancing productivity, safety, and profitability. By mastering selection, dedicating yourself to meticulous maintenance, and embracing a holistic view of the drive system, you ensure that this critical component consistently delivers reliable performance.