What Are Forklift Mast Roller Bearings and Why Are They Critical for Material Handling?

Forklift mast roller bearings represent precision-engineered components that serve as the backbone of smooth mast operation in material handling equipment. These specialized anti-friction devices are strategically positioned within the mast assembly to facilitate controlled vertical movement while supporting substantial loads. The importance of forklift mast roller bearings cannot be overstated, as they directly impact several key operational factors:

Comprehensive Role in Forklift Performance

- Load Distribution: Effectively transfers weight from the carriage and load across the entire mast structure

- Movement Precision: Enables controlled, smooth vertical travel without jerky motions that could destabilize loads

- Component Protection: Reduces metal-to-metal contact between mast channels and moving parts, preventing premature wear

- Energy Efficiency: Minimizes friction-related power losses in the lifting mechanism

- Safety Assurance: Maintains proper mast alignment to prevent dangerous operational conditions

The engineering behind these bearings has evolved significantly to meet increasing demands in modern warehouses. Contemporary forklift mast bearing rollers incorporate advanced materials and lubrication systems that extend service intervals while handling heavier loads than ever before. Proper selection and maintenance of these components can mean the difference between optimal productivity and costly downtime.

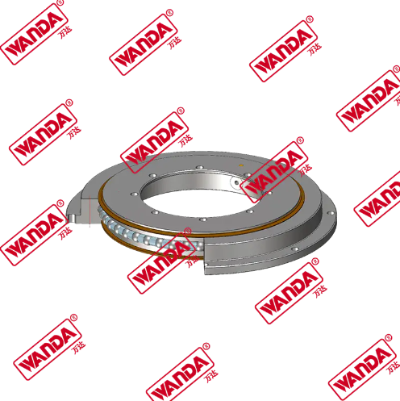

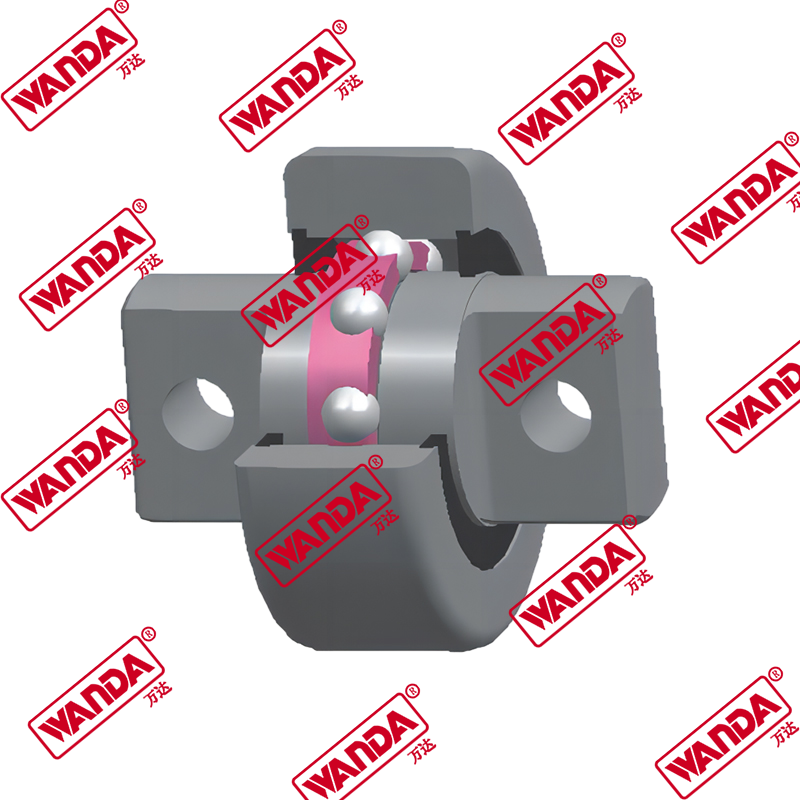

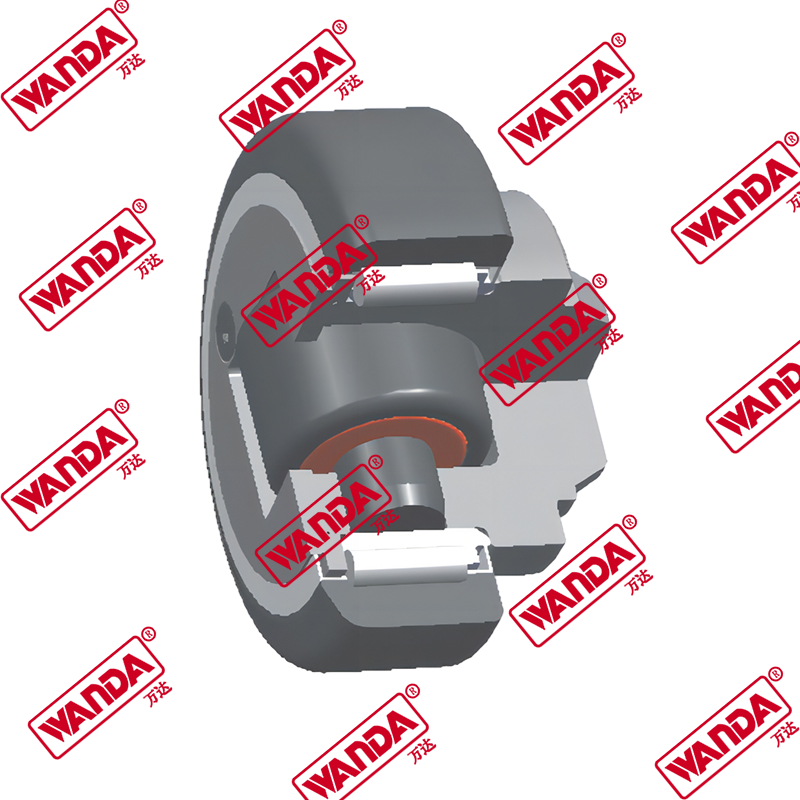

Detailed Examination of Forklift Mast Bearing Roller Types and Applications

The material handling industry utilizes several distinct bearing configurations, each designed to address specific operational requirements. Understanding these variations is essential for proper component selection and replacement.

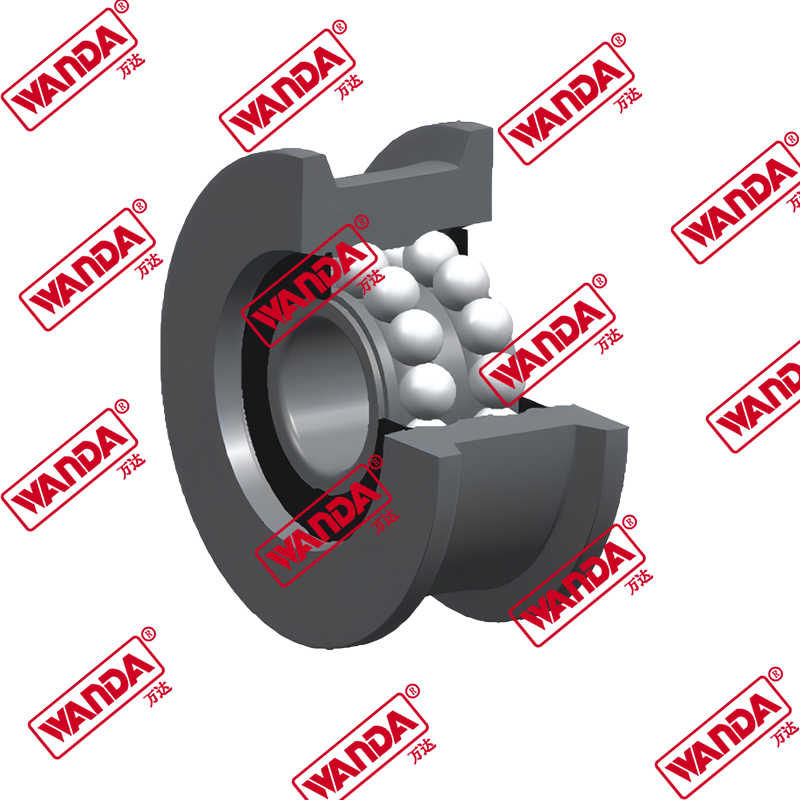

Needle Roller Bearing Systems

Characterized by their high length-to-diameter ratio, needle roller bearings excel in space-constrained applications. Their unique design offers:

- Space Efficiency: Provides maximum load capacity in minimal installation space

- Oscillation Performance: Maintains effectiveness in applications with limited rotational movement

- Radial Load Capacity: Superior performance under pure radial loading conditions

- Cost Effectiveness: Generally more economical than tapered alternatives for appropriate applications

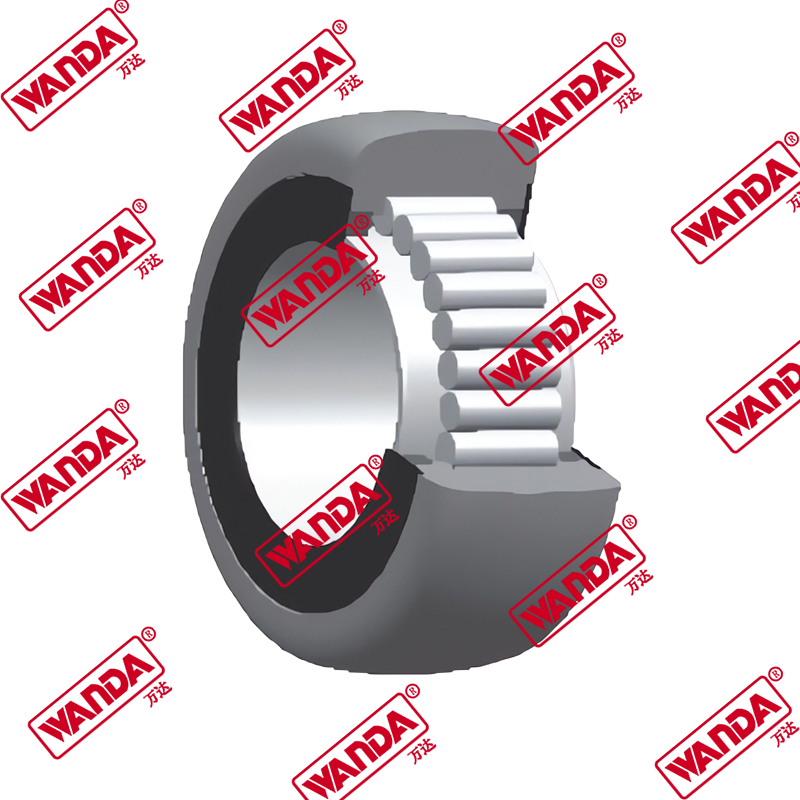

Tapered Roller Bearing Solutions

Engineered to handle combined loads, tapered roller bearings represent the premium choice for demanding applications:

- Combined Load Capacity: Simultaneously manages significant radial and axial forces

- Alignment Tolerance: Accommodates minor misalignment better than straight roller designs

- Adjustability: Permits precise clearance adjustments during installation

- Durability: Extended service life under heavy-duty cycling conditions

Technical Comparison of Bearing Types

| Parameter | Needle Roller | Tapered Roller | Cylindrical Roller |

|---|---|---|---|

| Radial Load Capacity | Excellent | Very Good | Exceptional |

| Axial Load Capacity | Limited | Excellent | Moderate |

| Space Requirements | Minimal | Moderate | Significant |

| Misalignment Tolerance | Low | High | Medium |

| Typical Applications | Compact masts | Heavy-duty lifts | Extreme capacity |

Advanced Warning Signs for Replacement Mast Rollers for Forklifts

Proactive identification of bearing wear prevents catastrophic failures and maintains operational safety. Modern maintenance programs should incorporate both scheduled inspections and real-time monitoring techniques.

Physical Inspection Indicators

- Surface Degradation: Visible pitting, spalling, or brinelling marks on rolling elements

- Contamination Evidence: Presence of debris in lubricant or bearing races

- Structural Damage: Cracked or deformed bearing cages or retainers

- Corrosion Patterns: Rust formation indicating seal failure or improper storage

- Lubricant Condition: Discoloration or texture changes suggesting breakdown

Operational Performance Metrics

Beyond physical signs, these operational changes suggest bearing issues:

- Temperature Variations: Abnormal heat generation in mast channels

- Hydraulic Pressure: Increased system pressure requirements for lifting

- Cycle Times: Noticeable slowing of mast movement speeds

- Vibration Patterns: New or intensified vibration during operation

- Alignment Issues: Developing fork tilt or mast twisting tendencies

Engineering Considerations for Heavy Duty Mast Roller Bearings Selection

Specifying the appropriate heavy-duty bearings requires thorough analysis of multiple technical factors that influence performance and longevity.

Load Analysis Methodology

Proper bearing selection begins with comprehensive load evaluation:

- Static Load Calculations: Determine maximum stationary load conditions

- Dynamic Load Analysis: Assess forces during movement and acceleration

- Shock Load Estimation: Account for potential impact forces

- Load Distribution: Evaluate how forces transfer through mast structure

- Safety Factors: Incorporate appropriate design margins

Environmental Adaptation Strategies

Specialized bearing configurations address challenging conditions:

- Corrosive Environments: Stainless steel construction with enhanced seals

- High-Temperature: Specialty lubricants and heat-treated components

- Contaminated Areas: Multi-labyrinth seal designs

- Food Processing: USDA-approved materials and lubricants

- Outdoor Applications: Weather-resistant coatings and seals

Comprehensive Maintenance Program for Forklift Mast Guide Rollers

Implementing a structured maintenance regimen significantly extends bearing service life and maintains optimal performance characteristics.

Advanced Lubrication Techniques

Modern lubrication practices go beyond basic greasing:

- Lubricant Selection: Matching viscosity and additives to operating conditions

- Application Methods: Utilizing precision lubrication tools for proper distribution

- Condition Monitoring: Oil analysis programs to detect wear particles

- Relubrication Intervals: Calculating based on operational hours and conditions

- Contamination Control: Maintaining clean lubrication pathways

Predictive Maintenance Technologies

Advanced monitoring techniques provide early failure detection:

- Vibration Analysis: Detecting developing faults through signature changes

- Thermography: Identifying abnormal heat patterns in mast channels

- Acoustic Monitoring: Capturing high-frequency bearing noises

- Wear Particle Analysis: Laboratory testing of lubricant samples

- Ultrasonic Testing: Detecting subsurface material flaws

Technical Troubleshooting for Forklift Mast Bearing Issues

Systematic diagnosis of bearing problems enables targeted repairs and prevents recurring issues.

Failure Mode Analysis

Understanding common failure mechanisms aids in prevention:

- Fatigue Spalling: Surface deterioration from repeated stress cycles

- Adhesive Wear: Material transfer due to lubrication breakdown

- Abrasive Wear: Particle contamination causing scoring

- Corrosive Damage: Chemical attack on bearing surfaces

- Plastic Deformation: Overload conditions causing permanent shape changes

Root Cause Investigation

Effective troubleshooting examines multiple potential factors:

- Installation Review: Checking for proper fitting and alignment

- Load Verification: Confirming actual versus design loads

- Environmental Audit: Assessing operating conditions

- Maintenance History: Reviewing service records and practices

- Operational Patterns: Analyzing usage cycles and behaviors