Understanding the Role of Forklift Spare Parts in Operational Efficiency

Forklift Spare Parts are a critical component in ensuring that material handling operations run smoothly and with minimal downtime. The performance, reliability, and safety of a forklift depend heavily on the quality and condition of its spare parts. When components such as brakes, hydraulic pumps, or lift chains wear out, operational efficiency can quickly decline, leading to increased maintenance costs and potential safety risks.

Using high-quality and well-maintained Forklift Spare Parts can:

- Reduce unexpected breakdowns

- Improve equipment uptime and productivity

- Enhance operator safety and confidence

- Lower total cost of ownership over the forklift’s lifespan

Key Operational Factors Influenced by Forklift Spare Parts

| Parameter | Impact on Operations | Example of Effect |

|---|---|---|

| Durability | Determines how often parts need replacement | Longer-lasting lift chains reduce downtime |

| Compatibility | Ensures correct fit and performance | Correct hydraulic seals prevent fluid leaks |

| Maintenance Frequency | Affects labor and downtime | Quality bearings require fewer service intervals |

| Safety Performance | Prevents accidents and equipment failure | Reliable brakes stop loads effectively |

| Energy Efficiency | Optimizes fuel or battery usage | Properly functioning motors reduce power loss |

When spare parts are chosen solely based on cost, without considering durability or compatibility, operational efficiency can suffer. For example, a low-cost but short-lived part may require frequent replacements, leading to higher cumulative expenses and repeated interruptions in workflow.

To maximize operational efficiency, businesses should establish a structured inspection and maintenance schedule for all Forklift Spare Parts, focusing on early detection of wear and tear. This approach not only extends the lifespan of the equipment but also safeguards productivity and safety standards.

Identifying the Right Forklift Spare Parts for Your Equipment

Selecting the correct Forklift Spare Parts is essential for maintaining performance, safety, and cost efficiency in material handling operations. The wrong part can lead to reduced productivity, mechanical failures, and unnecessary expenses. To make the right choice, operators and maintenance teams should follow a systematic approach.

Key Considerations When Choosing Forklift Spare Parts

1. Compatibility with Equipment Model

- Always match the spare part specifications—such as dimensions, weight capacity, and material type—to the forklift’s model requirements.

- Using incompatible parts can cause malfunctions or accelerate wear.

2. Material Quality and Durability

- Spare parts made from high-strength materials can withstand heavier loads and harsher working environments.

- Durable parts reduce replacement frequency, saving time and costs.

3. Performance Ratings

- Evaluate the load capacity, operating speed, and thermal resistance of the part to ensure it meets the operational demands.

4. Maintenance Requirements

- Some parts require frequent lubrication or cleaning, while others are designed for low-maintenance use.

- Choosing low-maintenance parts can reduce downtime in busy operations.

Parameter Comparison for Forklift Spare Parts Selection

| Parameter | High-Quality Spare Parts | Low-Quality Spare Parts |

|---|---|---|

| Service Life | 2–3 years or more | Less than 1 year |

| Load Capacity Tolerance | Within ±5% of rated capacity | May exceed ±10% deviation |

| Maintenance Frequency | Every 3–6 months | Monthly or more |

| Operational Safety | Meets industry safety standards | May fail under high stress |

| Initial Cost | Higher upfront cost | Lower upfront cost |

| Long-Term Cost | Lower due to fewer replacements | Higher due to frequent failures |

Best Practices for Selecting Forklift Spare Parts

- Keep a detailed parts manual for each forklift in your fleet.

- Work with suppliers who can provide verified technical specifications.

- Test-fit critical components before committing to bulk purchases.

- Maintain records of part performance to guide future procurement decisions.

By carefully evaluating specifications, durability, and performance ratings, businesses can ensure that the Forklift Spare Parts they choose will support safe and efficient operations while minimizing downtime and long-term costs.

The Comprehensive Guide to Forklift Spare Parts: Selection, Maintenance, and Cost Optimization Strategies

Forklift Spare Parts play a central role in keeping material handling operations reliable, safe, and cost-effective. A comprehensive approach—covering part selection, preventive maintenance, and cost optimization—ensures maximum return on investment while reducing downtime.

1. Selection Strategies for Forklift Spare Parts

Choosing the right spare parts involves balancing performance, safety, and budget considerations:

- Specification Accuracy – Match dimensions, load capacity, and material grade to the forklift’s operational needs.

- Environmental Suitability – Select parts that can withstand your working conditions, such as extreme temperatures, high humidity, or abrasive environments.

- Lifecycle Assessment – Consider the projected service life of the part compared to its cost.

Comparison Table: Selection Criteria for Forklift Spare Parts

| Selection Factor | High-Performance Option | Standard Option |

|---|---|---|

| Service Life | 3–5 years | 1–2 years |

| Load Capacity Match | ±3% of rated capacity | ±8% of rated capacity |

| Environmental Resistance | Excellent for harsh conditions | Limited to standard conditions |

| Initial Cost | Higher | Moderate |

| Total Cost of Ownership | Lower over time | Higher due to replacements |

2. Maintenance Strategies for Forklift Spare Parts

Proper maintenance extends the lifespan of forklift components and prevents sudden breakdowns:

- Scheduled Inspections – Regularly check wear-prone parts such as brakes, hydraulic seals, lift chains, and bearings.

- Preventive Replacement – Replace parts before they reach the end of their service life to avoid operational interruptions.

- Lubrication and Cleaning – Maintain moving parts to reduce friction, corrosion, and dust accumulation.

Parameter Comparison: Preventive vs. Reactive Maintenance

| Maintenance Type | Benefits | Drawbacks |

|---|---|---|

| Preventive | Minimizes downtime, extends part lifespan, improves safety | Requires planning and scheduled stops |

| Reactive | No upfront planning needed | Higher repair costs, unexpected downtime, reduced safety |

3. Cost Optimization Strategies for Forklift Spare Parts

Reducing costs without compromising quality requires a strategic approach:

- Inventory Management – Maintain an optimal level of critical spare parts to avoid emergency purchases.

- Bulk Procurement – Purchasing in larger quantities can reduce unit costs and shipping expenses.

- Condition-Based Replacement – Use performance monitoring data to replace parts based on actual wear, not just time intervals.

- Supplier Partnerships – Build long-term relationships for better pricing, warranty terms, and technical support.

Cost Analysis: Different Spare Parts Management Approaches

| Approach | Average Annual Cost | Downtime Risk |

|---|---|---|

| Proactive, Data-Driven | Low to Moderate | Very Low |

| Unplanned/On-Demand | High | High |

| Overstocking | High (due to unused inventory) | Low |

By combining precise selection, consistent maintenance, and smart cost-control strategies, businesses can maximize the value of their Forklift Spare Parts, ensuring that equipment remains safe, productive, and cost-efficient throughout its lifecycle.

Building a Long-Term Strategy for Forklift Spare Parts Management

A sustainable and efficient management plan for Forklift Spare Parts is essential for maintaining operational continuity, reducing costs, and extending equipment life. Long-term strategies go beyond short-term fixes, focusing instead on structured planning, technology adoption, and supplier collaboration to ensure a stable supply of high-quality parts.

1. Establishing a Predictive and Data-Driven Management System

Instead of relying on emergency replacements, companies should implement predictive maintenance systems. By using performance data from sensors and maintenance logs, it becomes possible to anticipate part wear and schedule replacements before failures occur. This approach significantly reduces downtime and improves productivity.

2. Partnering with Reliable, Quality-Focused Suppliers

A successful long-term strategy depends heavily on sourcing from suppliers with proven expertise and strict quality control.

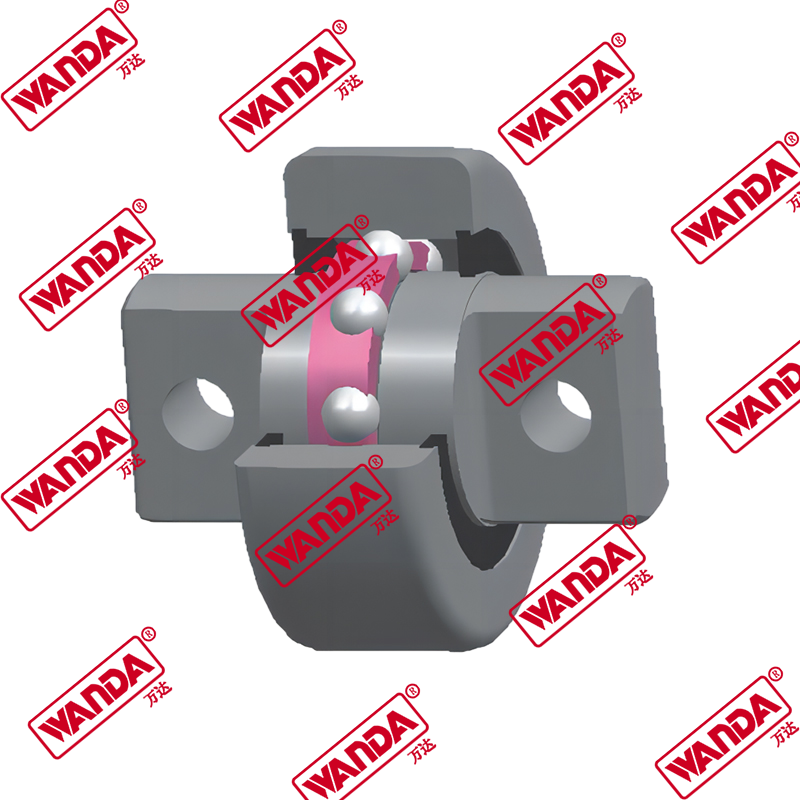

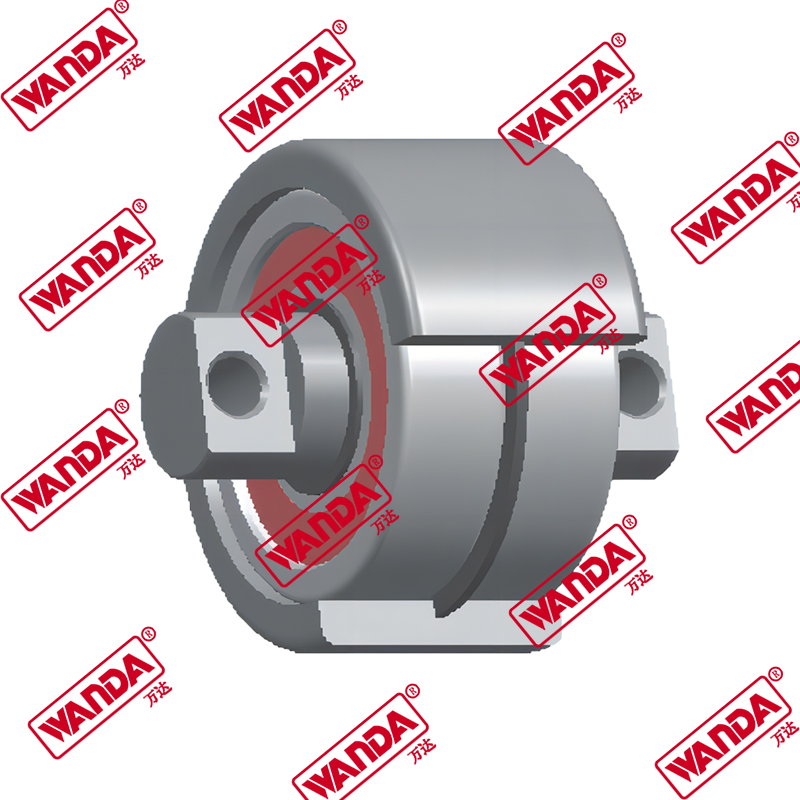

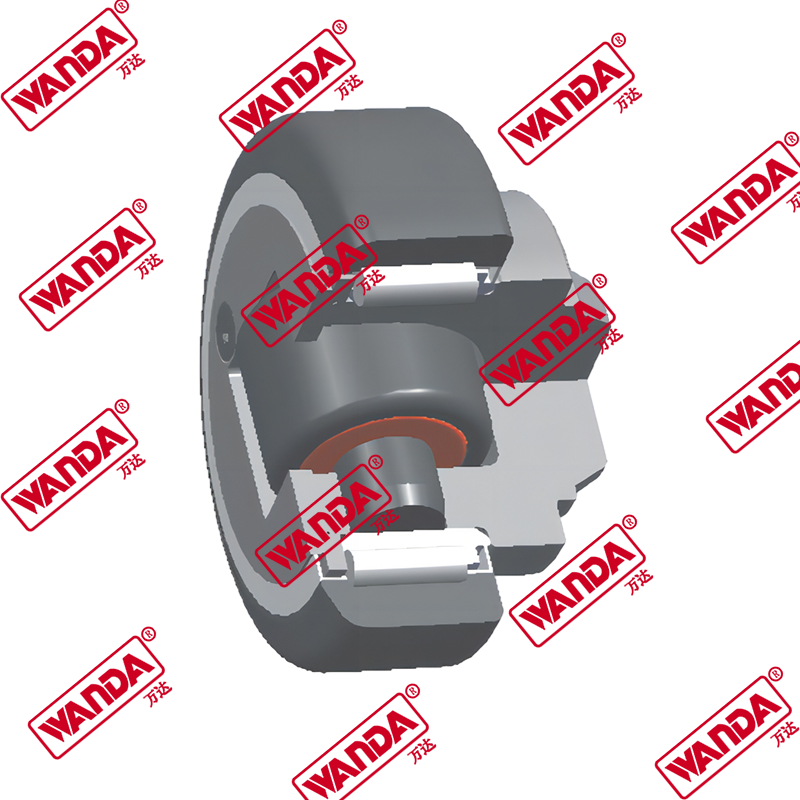

For example, Jiangsu Wanda Special Bearing Co., Ltd., established in September 2001 and with roots tracing back to the state-owned Rugao Bearing Factory in 1969, has become a recognized high-tech enterprise in China. Specializing in the R&D and production of specialized bearings for forklifts, the company adheres to EU material standards to meet the stringent requirements of the European market. With rigorous quality inspections and advanced manufacturing techniques, Jiangsu Wanda Special Bearing Co., Ltd. has earned trust both domestically and internationally—making it a strong example of the kind of supplier that supports sustainable spare parts management.

3. Balancing Inventory Levels for Forklift Spare Parts

Maintaining the right inventory level prevents costly stockouts while avoiding excessive storage costs. A well-balanced inventory strategy includes:

- Stocking critical parts with higher wear rates

- Using demand forecasts to plan purchases

- Implementing inventory management software to track usage trends

Parameter Comparison: Inventory Strategies for Forklift Spare Parts

| Strategy | Cost Impact | Downtime Risk | Waste Risk |

|---|---|---|---|

| Just-in-Time | Low storage cost | Medium to High | Low |

| Balanced Inventory | Moderate storage cost | Low | Low |

| Overstocking | High storage cost | Very Low | High (due to unused stock) |

4. Implementing Lifecycle Cost Analysis

Rather than focusing solely on purchase price, businesses should evaluate the total cost of ownership (TCO) for Forklift Spare Parts, considering factors such as service life, maintenance frequency, and impact on equipment efficiency.

Example TCO Factors for Forklift Spare Parts

- Initial purchase cost

- Expected service life in operational hours

- Maintenance and installation costs

- Downtime cost due to replacement frequency

5. Continuous Improvement and Training

Operator training on proper equipment handling can significantly extend the lifespan of forklift components. Additionally, reviewing spare parts performance data annually helps refine procurement and maintenance strategies.

By integrating predictive maintenance, partnering with trusted suppliers like Jiangsu Wanda Special Bearing Co., Ltd., optimizing inventory, and applying lifecycle cost analysis, businesses can build a long-term, resilient Forklift Spare Parts management strategy that ensures reliability, safety, and cost efficiency year after year.