Understanding the Critical Role of Genuine Forklift Spare Parts

The operational integrity of any material handling operation hinges on the reliability of its equipment. At the heart of this reliability are the components that keep forklifts running smoothly. Utilizing genuine and high-quality spare parts is not merely a recommendation; it is a fundamental requirement for safety, efficiency, and cost-effectiveness. Substandard or incorrect parts can lead to catastrophic equipment failure, posing significant safety risks to operators and other warehouse personnel, and resulting in costly downtime that disrupts entire supply chain operations. This section delves into the importance of investing in the right components, exploring how they contribute to the machine's overall health, longevity, and resale value. The decision to choose a particular part over another has long-term implications that every fleet manager must carefully consider.

When comparing genuine parts to generic alternatives, the differences extend beyond just the price tag. Genuine parts are engineered specifically for the make and model of your forklift, ensuring perfect fit, optimal performance, and adherence to the manufacturer's original specifications. They are tested rigorously for durability and safety under various operating conditions. On the other hand, while generic parts might be cheaper upfront, they often represent a false economy. Their failure rate is typically higher, they may void existing warranties, and their use can lead to increased wear on other connected components, creating a domino effect of malfunctions. For instance, a non-genuine brake pad might wear down quicker and also damage the brake rotor, leading to a repair cost that is multiples of the initial savings.

The following table outlines the key differences between genuine and generic forklift parts:

| Factor | Genuine Parts | Generic Parts |

|---|---|---|

| Compatibility & Fit | Engineered for a perfect, seamless fit with specific models. | Designed for a range of models, may require modification and not fit perfectly. |

| Quality & Materials | Manufactured with high-grade materials meeting original standards. | Variable quality; materials may be inferior to reduce costs. |

| Warranty | Typically covered by a manufacturer's warranty. | Warranties are often limited or non-existent, and may void the forklift's existing warranty. |

| Performance & Safety | Guaranteed to perform as intended, ensuring operational safety. | Performance can be unpredictable, potentially compromising safety. |

| Total Cost of Ownership | Higher initial cost but lower long-term cost due to reliability and longevity. | Lower initial cost but higher risk of premature failure and associated downtime costs. |

Making an informed choice requires understanding these distinctions. The initial investment in a genuine part safeguards against the immense indirect costs of operational downtime, which can far exceed the price of the part itself. Therefore, a strategic approach to procurement is essential for maintaining a productive and safe material handling environment.

Essential Forklift Components and Their Maintenance

A forklift is a complex machine comprising numerous systems that work in unison. Understanding these key systems and their critical components is the first step towards effective maintenance and informed sourcing of replacements.

The Power System: Engine and Battery Components

The power system is the lifeblood of the forklift, whether it's powered by an internal combustion (IC) engine or an electric battery. For IC engines, critical spare parts include air filters, oil filters, spark plugs, and fuel pumps. Regular replacement of these components is vital for maintaining engine efficiency, reducing harmful emissions, and preventing major breakdowns. Electric forklifts rely heavily on their battery and battery-related components. Proper care and timely replacement of parts like forklift battery water caps are crucial. These caps are designed to contain electrolyte spillage, prevent acid contamination, and ensure the correct pressure is maintained within the battery cell during charging. Using damaged or incorrect caps can lead to water loss, acid spills that damage the battery tray and truck, and reduced battery life and performance.

Key maintenance tips for the power system:

- Follow the manufacturer's strict service intervals for replacing filters and plugs.

- For electric models, regularly check and maintain proper water levels using distilled water and ensure forklift battery water caps are securely fastened and not cracked.

- Use only recommended grades of oil and fuel for IC engines to ensure optimal performance of the new components.

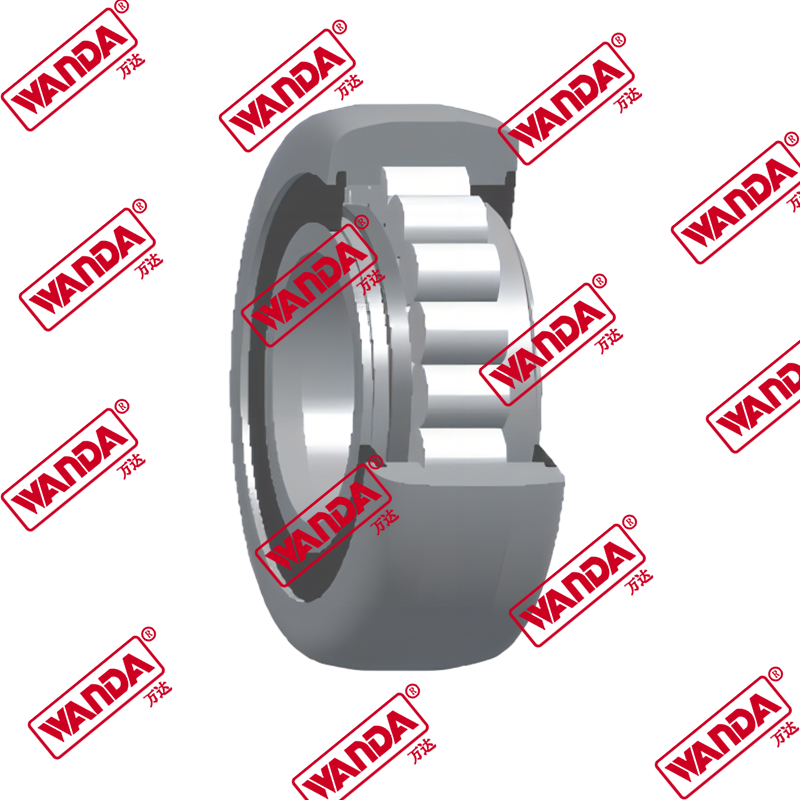

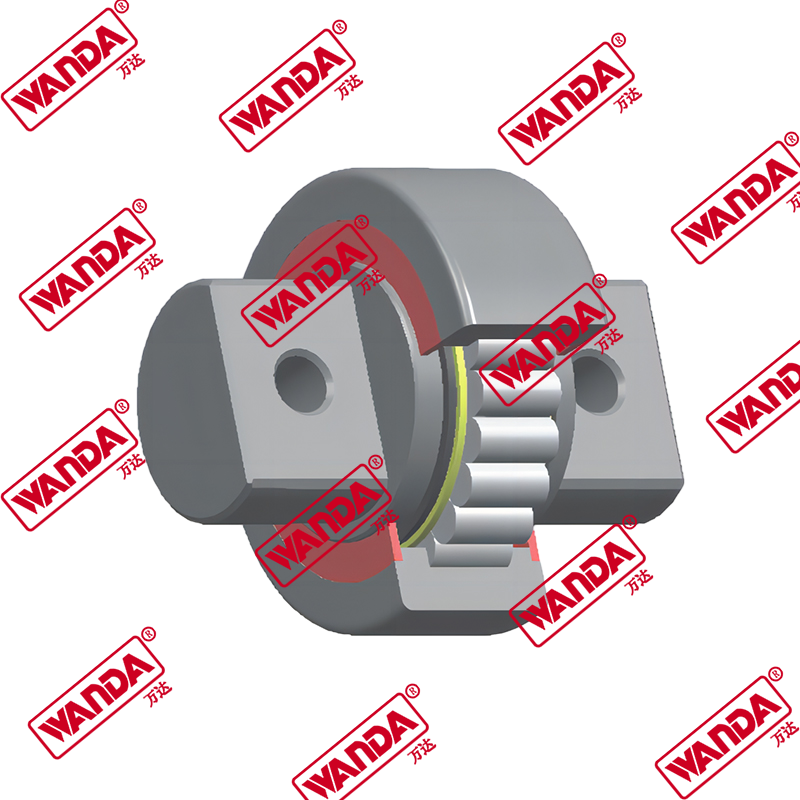

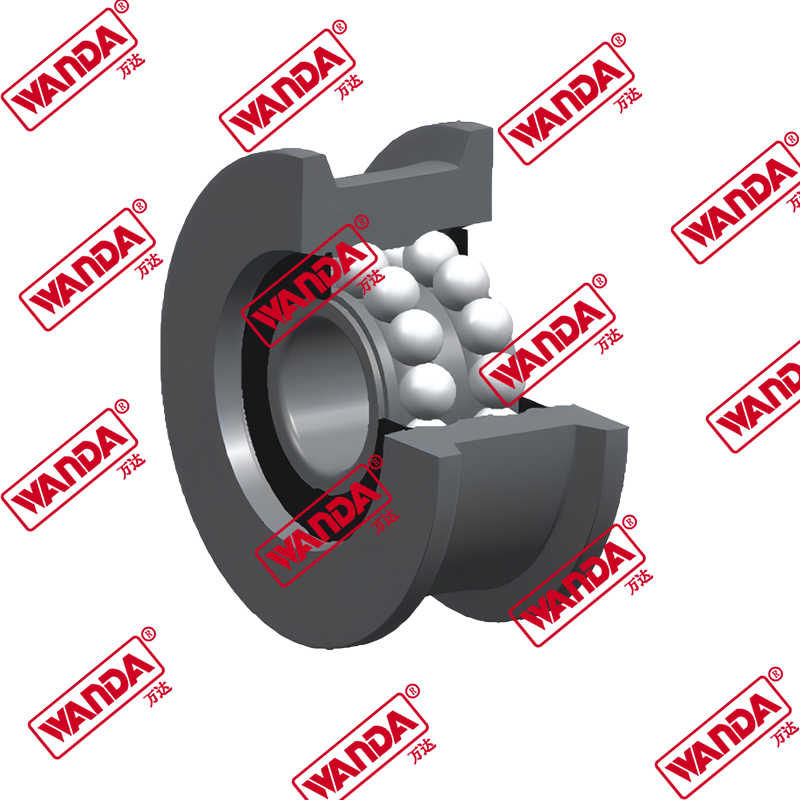

The Hydraulic System: Lifting and Tilting

The hydraulic system is responsible for the forklift's primary function: lifting and lowering loads. Key components in this system include hydraulic pumps, control valves, lift cylinders, and tilt cylinders. Wear and tear in these components manifest as slow lifting, drifting loads, or inability to reach full height. Sourcing high-quality hydraulic seals is particularly important, as leaks in this system lead to a rapid loss of performance and potential environmental hazards from hydraulic fluid spills. Regular checks for leaks and fluid levels are simple yet effective preventative measures.

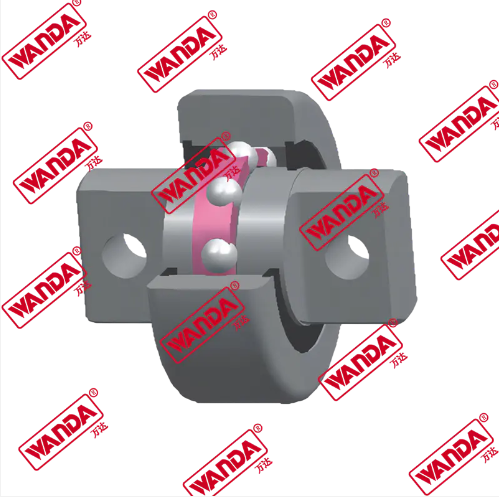

The Mast Assembly: Chains, Rollers, and Carriage

The mast is the vertical assembly that lifts the load. Its smooth operation depends on several wear parts. Forklift mast chains are under immense tension and stress every time a load is lifted. Regular inspection for stretch, wear, and cracks is critical to prevent catastrophic failure. Similarly, mast rollers guide the inner channels of the mast and wear down over time. A worn roller can cause the mast to operate roughly or become misaligned. The carriage, which the forks are mounted to, also contains bearings and hooks that need inspection.

The Braking System: Ensuring Safety

There is no room for compromise when it comes to the braking system. Key parts include brake pads, shoes, drums, and the hydraulic components of the brake system. Worn-out brake parts significantly increase stopping distances and pose a severe safety risk. Symptoms of wear include squealing noises, a spongy brake pedal, or the truck pulling to one side when braking. Parts for this system must always be genuine or of certified quality to guarantee the specified performance.

The Electrical System: Ignition and Sensors

Modern forklifts, especially electric models, feature complex electrical systems. This includes starters, alternators, sensors, and wiring harnesses. Problems here can be difficult to diagnose but can shut down operations entirely. A faulty sensor can cause a forklift to go into a safety shutdown mode, while a failing starter motor will prevent the engine from running. Using reliable replacement parts ensures that these sensitive systems function correctly and communicate properly with the forklift's onboard computers.

Identifying and Sourcing Reliable Spare Parts

Finding a trustworthy source for forklift spare parts online has become the standard for many businesses, offering convenience and a wider selection. However, the digital marketplace requires diligence to avoid counterfeit products and unreliable vendors.

Strategies for Verifying Part Quality and Authenticity

Before purchasing, especially online, it is crucial to verify the seller's credibility. Look for suppliers who specialize in forklift parts and have established a strong reputation within the industry. Check for customer reviews, testimonials, and their policies on returns and warranties. Always have your forklift's model number, serial number, and part number from the old component on hand. Cross-referencing these numbers with the seller's listing is the best way to ensure compatibility. Be wary of prices that seem too good to be true, as they often indicate counterfeit or inferior quality parts.

The Importance of OEM and Aftermarket Standards

Original Equipment Manufacturer (OEM) parts are made by the same company that manufactured the original part for the forklift. They offer the highest assurance of compatibility and quality. Aftermarket parts, produced by third-party companies, can be a viable alternative if they are made to meet or exceed OEM specifications. Reputable aftermarket manufacturers invest heavily in research and development to produce high-quality parts. The key is to distinguish between these reputable manufacturers and producers of low-quality imitations. When searching for forklift spare parts online, use filters to look for OEM or "premium" aftermarket brands that are well-known and respected.

Step-by-Step: Replacing a Forklift Wheel

Replacing a forklift drive wheel is a common maintenance task that, while manageable, must be performed with care and attention to safety. The drive wheel is a critical component for traction and movement, and its wear directly affects operational stability.

Safety First: Preparing for the Replacement

Before any work begins, the forklift must be completely shut down. Park on a flat, level, and solid surface. Lower the forks completely to the ground. Engage the parking brake. For extra safety, chock the wheels that will remain on the ground. Disconnect the battery on an electric forklift to prevent accidental ignition or electrical shock. Gather all necessary tools beforehand, including a jack rated for the forklift's weight, jack stands, lug wrenches, and the new forklift drive wheel. Never rely solely on a jack to support the forklift; always use jack stands once the truck is lifted.

The Removal and Installation Process

Once the forklift is securely elevated and supported, you can begin the wheel removal. Loosen the lug nuts before lifting the truck completely. After lifting and securing with jack stands, remove the lug nuts completely and pull the wheel off the axle. Carefully clean the axle hub surface before installing the new wheel. Mount the new wheel onto the axle, hand-tighten the lug nuts in a star pattern to ensure even seating, and then lower the forklift until the tire just touches the ground. Finally, fully torque the lug nuts to the manufacturer's specification using a torque wrench, again following a star pattern. This ensures the wheel is mounted evenly and securely, preventing vibration and loosening during operation.

Troubleshooting Common Hydraulic Issues

Hydraulic problems are a frequent cause of forklift downtime. Understanding how to diagnose these issues can save valuable time and resources.

Diagnosing Slow Lifting and Load Drift

If the mast lifts slowly or cannot reach its full height, the primary suspects are low hydraulic fluid levels, a clogged hydraulic filter, or a worn hydraulic pump. Load drift, where the mast slowly lowers by itself, typically points to worn seals in the lift cylinders or a malfunctioning control valve. Internal leakage within these components prevents them from holding pressure. A visual inspection for external leaks should always be the first step. For complex issues like internal valve problems, consultation with a qualified technician is often necessary.

Resolving Noisy Pump Operation

A loud whining or cavitation noise from the hydraulic pump usually indicates that it is starved for fluid. This is often caused by a clogged inlet filter or a low fluid level. Running the pump in this state can cause severe and rapid damage. Immediately check the fluid level and inspect the filters. If the fluid is old or contaminated, a full system flush and fluid replacement may be required after replacing the filters.

Maximizing the Value of Your Spare Parts Inventory

For businesses operating multiple forklifts, maintaining a strategic inventory of spare parts is a key aspect of efficient fleet management. This minimizes downtime by having critical components on hand when needed.

Conducting a Cost-Benefit Analysis for Parts Stocking

Not every part needs to be kept in inventory. The decision should be based on a cost-benefit analysis that considers the part's criticality, its failure rate, and its lead time. Fast-moving consumables like filters and forklift spark plugs are ideal for stocking because they are replaced frequently and their failure can lead to other engine problems. Similarly, having a common forklift drive wheel on hand can get a truck back to work quickly. The goal is to find a balance between the carrying cost of inventory and the potential cost of downtime for a specific part's failure.

Implementing an Organized Inventory Management System

An organized system is crucial for an effective spare parts inventory. This involves:

- Categorizing parts by system (e.g., engine, hydraulic, electrical).

- Clearly labeling parts with descriptive names and part numbers.

- Storing parts in a clean, dry, and secure environment to prevent deterioration.

- Using a tracking system, whether digital or manual, to monitor stock levels and usage patterns. This data helps refine your stocking strategy over time, ensuring you have the right parts, like a set of forklift spark plugs, when you need them without over-investing in slow-moving items.

Selecting the Right Braking Components for Your Fleet

The braking system is non-negotiable when it comes to safety. Choosing the correct components is a critical decision.

Comparing Brake Pad Materials and Applications

Brake pads are made from different materials, each suited to specific operating environments. Organic pads are quieter and work well in standard warehouse applications but may wear faster. Semi-metallic pads offer better heat resistance and durability, making them suitable for more demanding use. Ceramic pads provide the best performance, offering excellent stopping power, low noise, and minimal dust, but they come at a higher cost. The choice depends on the intensity of your operations, ambient temperatures, and budget.

The Long-Term Impact of Quality Braking Parts

Investing in high-quality braking parts has a direct impact on the total cost of ownership. Superior pads and shoes last longer, require less frequent replacement, and provide consistent performance throughout their life. More importantly, they protect other, more expensive components like rotors and drums from excessive wear. This means that while the initial purchase price might be higher, the long-term maintenance costs are lower, and most importantly, the safety of your operation is maintained at the highest possible level.