Understanding the Critical Role of Forklift Wheel Chains

Within the intricate ecosystem of material handling equipment, the forklift stands as a pillar of industrial and warehouse operations. While much attention is given to engines, forks, and masts, the drive system, particularly the forklift wheel chain, is a fundamental yet often overlooked component. This robust assembly is responsible for transmitting power from the drive motor directly to the wheels, enabling movement, lifting, and precise maneuvering under significant loads. Unlike standard chains, those designed for forklifts are engineered to withstand immense stress, shock loads, and harsh environmental conditions, making their selection, maintenance, and understanding paramount for operational safety and efficiency. A failure in this critical link can lead to costly downtime, unsafe working conditions, and potential damage to both the forklift and its surrounding environment. This guide delves deep into the world of forklift wheel chains, providing a comprehensive resource for operators, fleet managers, and maintenance professionals.

Five Essential Long-Tail Keywords for Forklift Wheel Chain Inquiry

For those seeking specific information, certain search queries are more precise than others. These long-tail keywords often indicate a user moving beyond basic knowledge and into a phase of research, troubleshooting, or purchase intent. They typically have lower competition than broader terms, making them valuable for targeted information retrieval. The following five phrases are crucial for anyone looking to gain a deeper understanding of this component:

- heavy duty forklift drive chain specifications

- how to adjust tension on forklift wheel chain

- forklift chain replacement cost factors

- signs of wear on forklift axle chain

- difference between roller chain and leaf chain in forklifts

This article will explore each of these topics in detail, providing the in-depth knowledge required to make informed decisions.

Deciphering Heavy Duty Forklift Drive Chain Specifications

Selecting the correct chain for a forklift is not a matter of guesswork; it requires a meticulous understanding of its specifications. Using an incorrect chain can lead to premature failure, safety hazards, and voided warranties. The specifications for a heavy-duty drive chain are a blueprint of its capabilities and limitations.

Key Specification Parameters

Several critical parameters define a forklift wheel chain. Understanding each is essential for ensuring compatibility and performance.

Pitch and Gauge

The pitch is the distance between the centers of two adjacent pins, typically measured in inches or millimeters. A larger pitch often indicates a chain capable of handling higher loads, but it must perfectly match the sprockets on the drive axle. The gauge refers to the thickness of the side plates, which directly contributes to the overall tensile strength of the chain.

Tensile Strength and Working Load Limit

Tensile strength is the maximum load a chain can withstand in a single pull before breaking. This is a ultimate strength value. More important for daily operation is the Working Load Limit (WLL), which is the maximum load that should ever be applied to the chain during service. The WLL is calculated with a significant safety factor built-in (often 4:1 to 8:1 for forklifts) to account for dynamic stresses, shock loads, and wear over time.

International Standards and Grades

Chains are manufactured to various international standards (e.g., ANSI, ISO) which define their dimensions, tolerances, and minimum strength values. Furthermore, chain grade (e.g., Grade 40, 80, 100) indicates the material's yield strength. A higher grade number signifies a stronger chain made from alloy steel, which is essential for the high-stress environment of a forklift drive system.

Importance of OEM Specifications

Always cross-reference any replacement chain with the original equipment manufacturer's (OEM) specifications. The forklift's model number and serial number are key to finding the exact part number for the required chain. Deviating from these specifications, even with a chain that appears similar, can have catastrophic consequences for the drive train's integrity.

Mastering How to Adjust Tension on Forklift Wheel Chain

Proper chain tension is arguably the most critical aspect of routine maintenance. A chain that is too loose can whip, jump off the sprocket, or cause excessive wear. A chain that is too tight places immense strain on the chain itself, the sprockets, and the bearings of the drive motor, leading to premature failure of all components.

Step-by-Step Adjustment Procedure

Adjusting chain tension is a precise task that should be performed on a level surface with the forklift completely stopped and powered off, with the parking brake engaged.

- Locate the Adjustment Points: The method varies by forklift model. Common systems involve adjusting nuts on the drive axle or shims between the axle housing and the frame.

- Measure the Current Tension: The correct method is usually specified in the service manual. It often involves applying a specific force to the chain at a midpoint between the sprockets and measuring the deflection. For example, a typical specification might be 1/4 inch of deflection per foot of chain span.

- Perform the Adjustment: If using adjustment nuts, loosening the locknuts and turning the adjustment nuts will typically move the axle away from the motor (increasing tension) or towards it (decreasing tension). Re-tighten the locknuts securely after adjustment.

- Re-check Tension: After making an adjustment, always re-measure the tension. It is also crucial to rotate the wheels several times and re-check, as the tension can vary slightly depending on the position of the chain.

Common Mistakes to Avoid

- Overtightening: This is the most frequent and damaging error. It does not improve performance; it only accelerates wear.

- Ignoring Sprocket Wear: Attempting to adjust tension on a worn-out sprocket is futile. Worn sprockets have a hooked tooth profile that will quickly destroy a new, properly tensioned chain.

- Inconsistent Checks: Tension should be checked as part of a scheduled maintenance program, not just when a problem is suspected.

Analyzing Forklift Chain Replacement Cost Factors

The cost of replacing a forklift wheel chain is not simply the price of the chain itself. Several variables contribute to the total cost of ownership and replacement, making it difficult to state a single price. Understanding these factors allows for better budgeting and decision-making.

Primary Cost Components

The total replacement cost is a sum of parts, labor, and potential ancillary costs.

Cost of the Chain Assembly

This is the most variable factor. A standard-duty chain for a smaller electric forklift will be significantly less expensive than a heavy duty forklift drive chain for a large-capacity internal combustion forklift. Chains are often sold as complete assemblies, which may include connecting links and pins.

Labor Costs

The complexity of the replacement job greatly influences labor time. Some forklifts allow for chain replacement with minimal disassembly, while others require the removal of wheels, hub assemblies, or even the drive motor. Shop labor rates vary geographically and by service provider.

Additional Parts and Ancillary Costs

It is almost always recommended to replace the chain and sprockets as a matched set. Installing a new chain on worn sprockets is a false economy. Therefore, the cost of new sprockets must be factored in. Additionally, seals, gaskets, and bearings disturbed during the repair may also need replacement. Perhaps the largest hidden cost is downtime. A forklift out of service represents a loss of productivity, which can far exceed the mechanical repair costs.

Comparison of Cost Scenarios

The following table illustrates how different factors influence the total cost of a chain replacement project.

| Factor | Low-Cost Scenario | High-Cost Scenario |

|---|---|---|

| Forklift Size | Small electric pallet jack | Large container handler |

| Chain Type | Standard roller chain | Custom high-grade leaf chain |

| Labor | In-house maintenance, simple access | Dealer service tech, extensive disassembly required |

| Additional Parts | Chain only | Chain, both sprockets, bearings, and seals |

| Downtime Impact | Low season, multiple spare forklifts available | Peak season, critical single-point operation |

Identifying the Signs of Wear on Forklift Axle Chain

Proactive inspection is the key to preventing unexpected chain failure. Regular visual and manual checks can identify problems long before they lead to a breakdown. Operators and maintenance personnel should be trained to recognize the following telltale signs of wear.

Visual Indicators of Wear

A thorough visual inspection should be conducted with a flashlight, looking for specific anomalies.

Elongation (Stretch)

While chains don't stretch like a rubber band, the wear at the pin and bushing interfaces increases the pitch length, effectively elongating the chain. This is the most common form of wear. It can be measured precisely with calipers or a chain wear gauge tool. A chain that has elongated beyond the manufacturer's recommended limit (often 1.5% to 2% over original length) must be replaced.

Surface Cracks and Rust

Look for cracks, particularly in the side plates and rollers. These are often signs of metal fatigue or improper heat treatment. Surface rust can be cleaned and treated, but deep pitting rust weakens the metal and creates stress points that can lead to catastrophic failure.

Functional Indicators and Audible Cues

How the chain performs and sounds during operation provides critical diagnostic information.

Sprocket Engagement and "Ride-Out"

A worn chain will not sit correctly in the sprocket grooves. You may observe the chain "riding" high on the sprocket teeth. In severe cases, the chain may even skip a tooth under load, producing a loud clunking sound and causing jerky movement.

Unusual Noises

A well-lubricated and tensioned chain should operate relatively quietly. Grinding, squealing, or repetitive clicking noises often indicate a lack of lubrication, a stiff or seized link, or that the chain is making contact with another part of the chassis.

Regularly identifying these signs of wear on forklift axle chain is the most effective strategy for moving from reactive repairs to predictive maintenance, saving significant time and money.

Exploring the Difference Between Roller Chain and Leaf Chain in Forklifts

Not all chains are created equal, and understanding the fundamental types used in forklifts is crucial. The two most common types are roller chains and leaf chains (also known as forklift mast chains or crane chains), and they serve distinctly different purposes, though sometimes in the same machine.

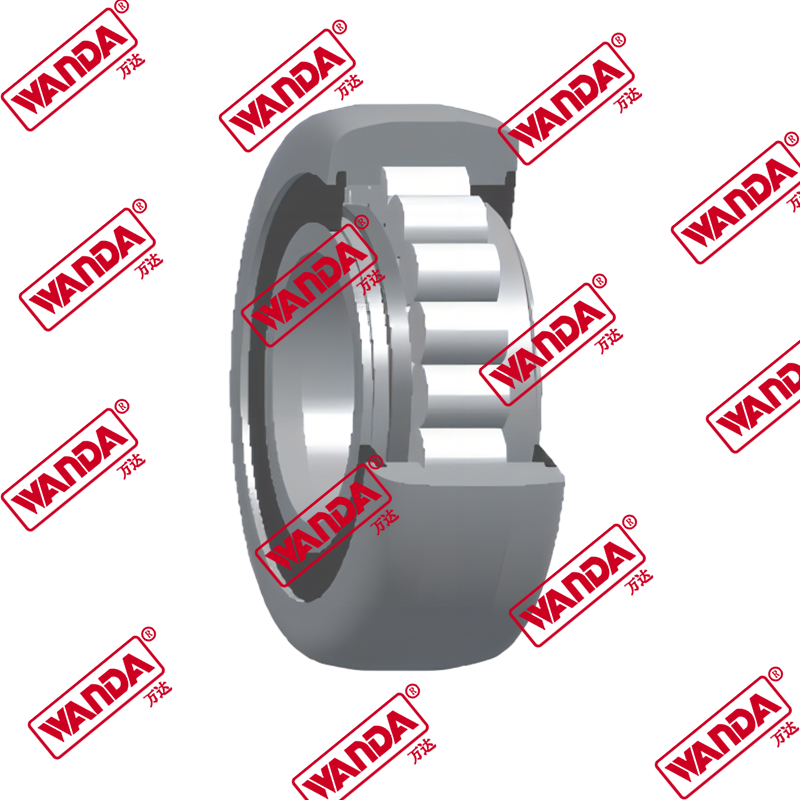

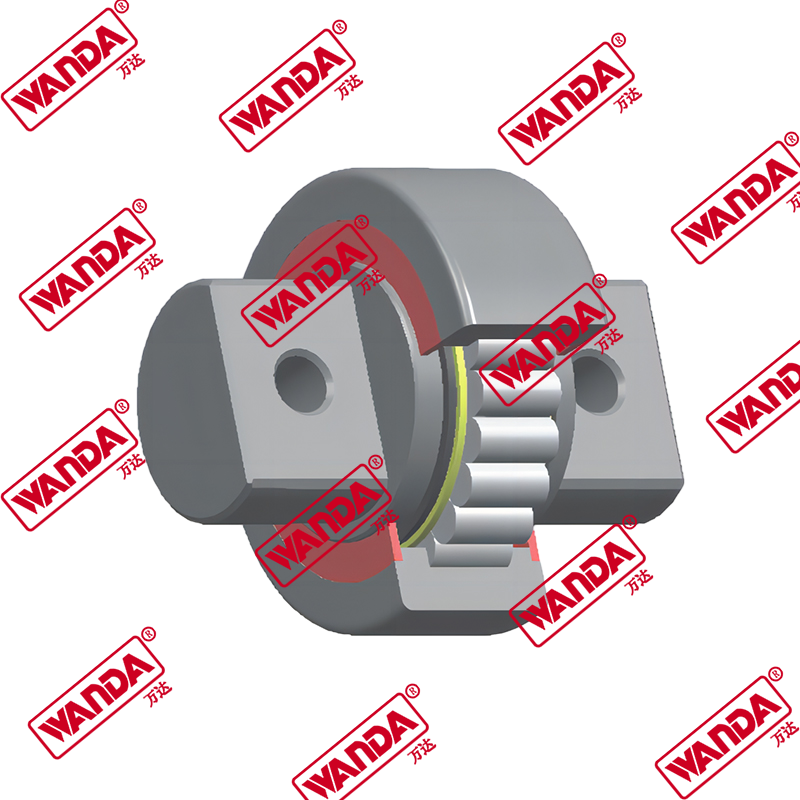

Roller Chain: The Drive System Workhorse

Roller chains are almost exclusively used in the drive system to power the wheels. Their design is optimized for transmitting rotational power efficiently.

- Design: Consists of inner plates, outer plates, pins, bushings, and rollers. The rollers rotate on the bushings, providing smooth engagement with the sprocket teeth and reducing friction.

- Function: Designed for high-speed, continuous power transmission in a single direction (though they can run in reverse).

- Application in Forklifts: Used exclusively for the drive function, connecting the output shaft of the transmission or drive motor to the axle sprockets.

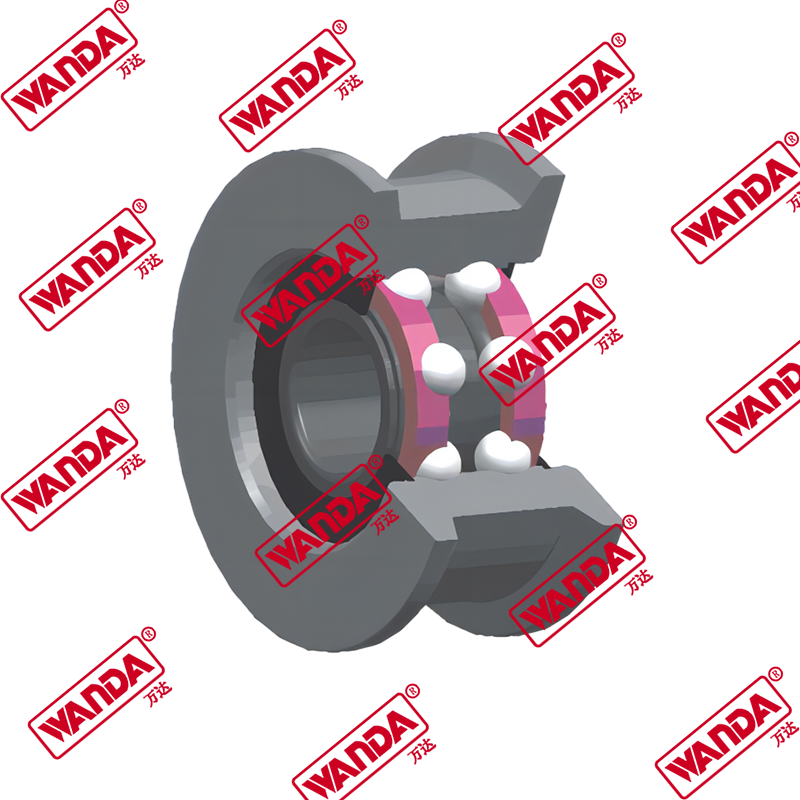

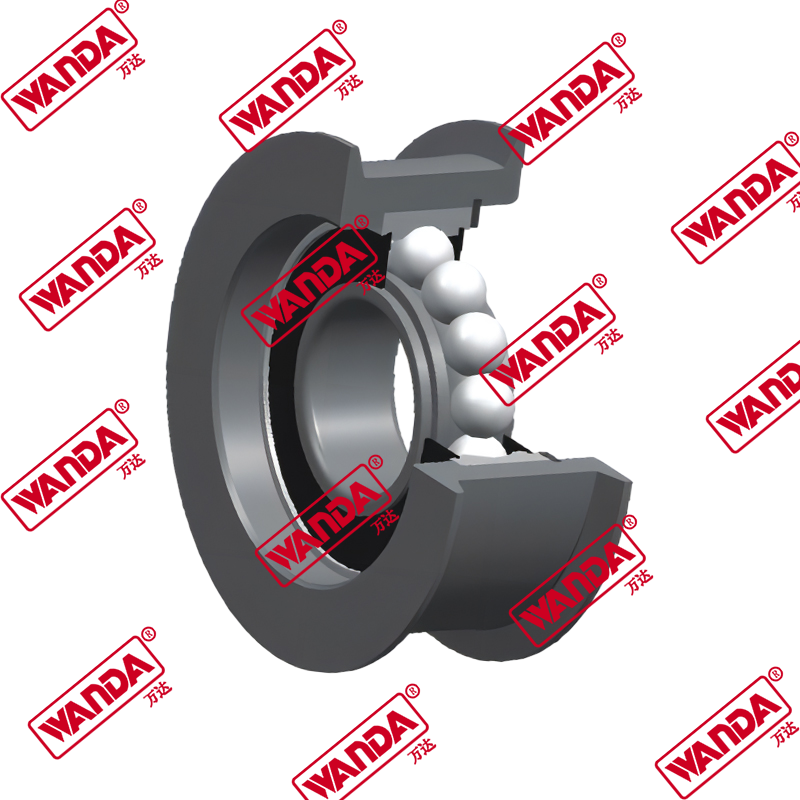

Leaf Chain: The Lifting Specialist

Leaf chains are designed for linear lifting applications, where pure tensile strength is the primary requirement.

- Design: Constructed from multiple parallel sets of inner and outer plates (leaves) assembled on pins. There are no rollers; the chain articulates directly on the pins.

- Function: Engineered for high tensile strength and minimal elongation under load in a straight-pull configuration. They are not designed for high-speed operation over sprockets.

- Application in Forklifts: Primarily used inside the mast to lift the carriage and forks. They are routed over sheaves and connected to the hydraulic lift cylinder.

Key Differences Summary

The following table clearly outlines the critical distinctions between these two chain types, highlighting why each is suited to its specific role.

| Feature | Roller Chain | Leaf Chain |

|---|---|---|

| Primary Function | Power Transmission (Rotation) | Linear Lifting (Tension) |

| Key Components | Inner/outer links, pins, bushings, rollers | Multiple stacked leaf plates assembled on pins |

| Articulation & Friction | Roller rotates on bushing for smooth engagement | Plates articulate directly on pins; higher friction |

| Design Focus | Efficiency, speed, durability over sprockets | Maximum tensile strength, minimal stretch |

| Common Forklift Application | Drive wheel axle | Mast lift mechanism |

Understanding this difference between roller chain and leaf chain in forklifts prevents the critical error of using the wrong type of chain for a repair, which would be dangerous and lead to immediate failure.

Implementing a Proactive Forklift Chain Maintenance Program

Knowledge of specifications, adjustment, and wear signs is only valuable if applied within a structured maintenance program. A proactive approach maximizes chain life, ensures safety, and minimizes the total forklift chain replacement cost factors.

Core Elements of an Effective Program

A successful program is built on consistency, documentation, and the right tools.

Scheduled Inspection Intervals

Establish formal intervals for chain inspection based on operating hours. For intensive applications, a daily visual check by the operator and a weekly detailed measurement by a technician may be required. For lighter use, a monthly inspection might suffice. These intervals should be documented in a maintenance log for each forklift.

Proper Lubrication Procedures

Lubrication reduces wear, protects against corrosion, and can dissipate heat. Use the type of lubricant specified by the forklift manufacturer. Apply it correctly—aiming for the interfaces between pins and bushings/rollers while the chain is warm after operation, which helps the lubricant wick into the gaps. Avoid over-lubrication, as excess grease can attract abrasive dirt and grime.

Training and Documentation

Ensure that everyone involved—from operators to senior technicians—understands the importance of the chain system and can perform their part of the inspection routine. Maintain detailed records of all adjustments, lubrications, and replacements. This history is invaluable for diagnosing recurring issues and predicting future replacement needs.

By integrating the knowledge of how to adjust tension on forklift wheel chain and the ability to spot the signs of wear on forklift axle chain into a regular schedule, businesses can transform their maintenance strategy from a cost center into a strategic asset that guarantees reliability and safety on the warehouse floor.