Replacing a worn-out forklift combined roller bearing is a critical maintenance task that directly impacts the safety, performance, and longevity of your material handling equipment. These complex bearings are integral to the smooth operation of the mast, enduring immense loads and constant movement. When the time comes for a replacement, the central question faced by fleet managers and maintenance technicians is whether to choose an OEM part or an aftermarket alternative. This decision is not merely about cost; it involves a careful evaluation of quality, compatibility, warranty, and the total cost of ownership. This comprehensive guide delves deep into the nuances of both OEM and aftermarket forklift combined roller bearing options, providing you with the detailed information needed to make an informed, cost-effective, and safe choice for your operations. We will explore the technical specifications, performance benchmarks, and real-world implications of each option, moving beyond price tags to consider what truly matters: minimizing downtime and ensuring operational reliability.

Understanding the Forklift Combined Roller Bearing

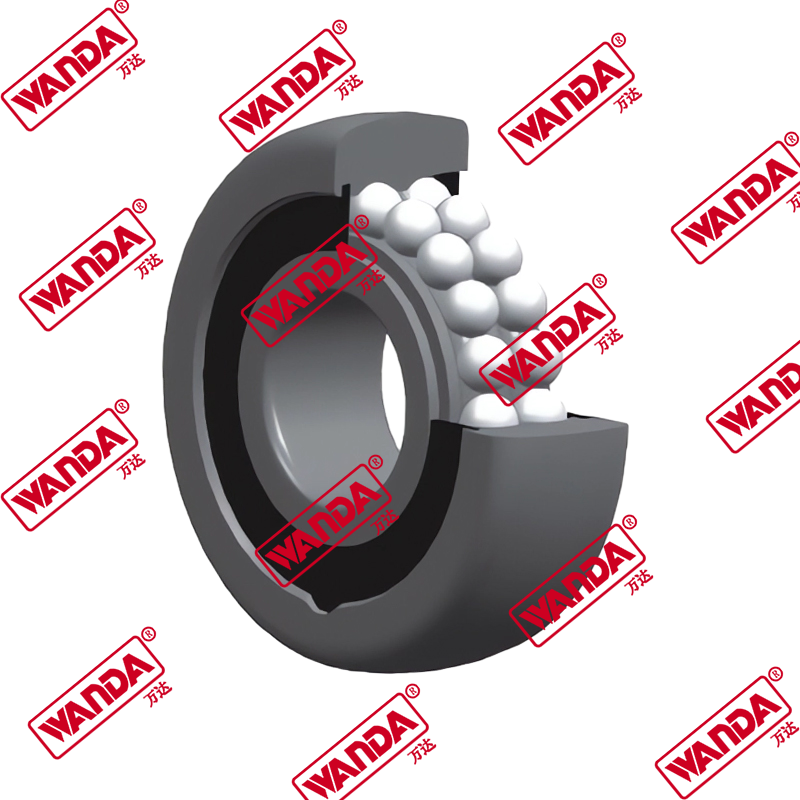

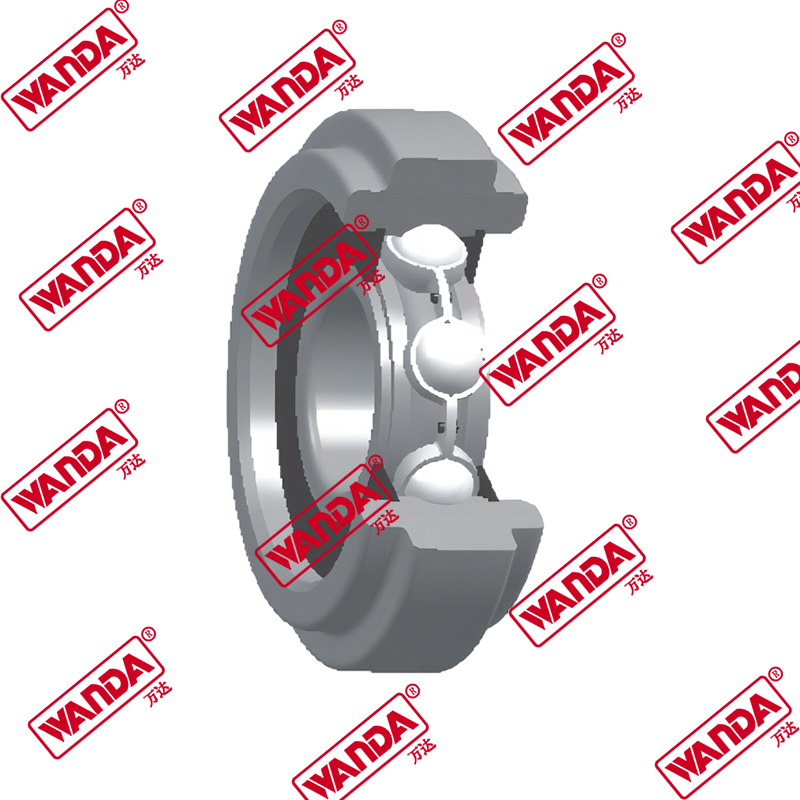

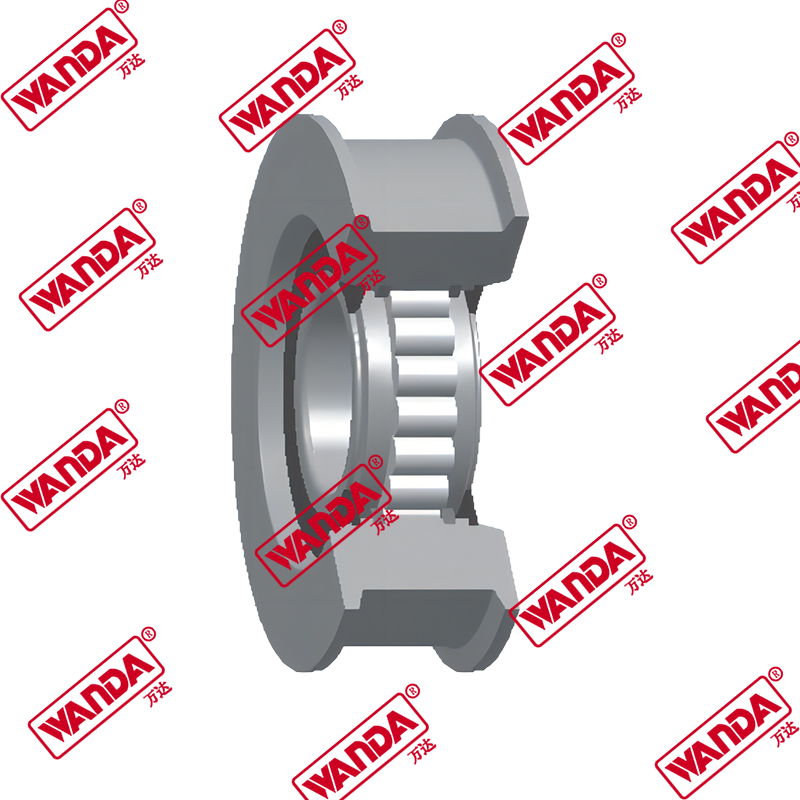

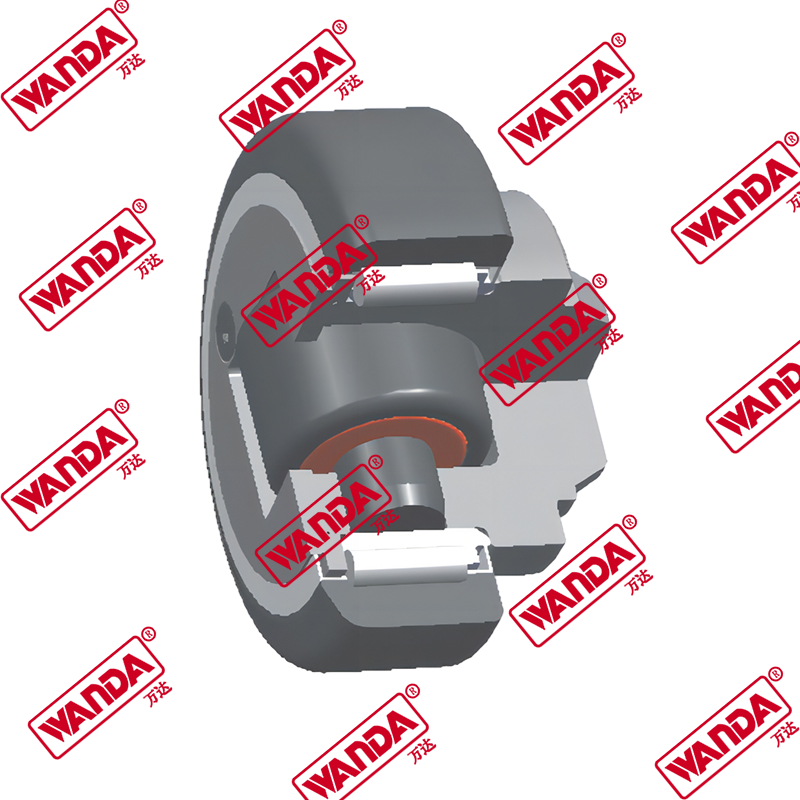

Before delving into the replacement options, it is crucial to understand the role and significance of the combined roller bearing assembly. Unlike a simple bearing, this component is a pre-assembled unit that typically combines a radial needle roller bearing and a thrust ball bearing into a single, compact housing. This design allows it to handle both the radial loads from the mast's vertical movement and the axial (thrust) loads encountered when the mast tilts forward or backward. It is a precision component that operates under high stress and with minimal clearance. Failure of this bearing can lead to catastrophic mast failure, uneven lifting, excessive play, and significant safety hazards. Therefore, the quality and precision of the replacement part are not areas for compromise. Understanding its function underscores why the choice between OEM and aftermarket is so pivotal, affecting everything from forklift mast bearing noise levels to the overall stability of the load.

- Function: Manages combined radial and axial loads during mast extension/retraction and tilting.

- Construction: A single unit housing needle rollers for radial load and ball bearings for thrust load.

- Importance: Ensures smooth, precise, and safe mast operation; premature failure risks expensive downtime and repairs.

- Common Failure Signs: Increased forklift mast bearing noise (grinding, popping), mast wobble, difficulty tilting, and uneven lifting.

OEM Forklift Bearings: The Benchmark for Quality and Fit

Original Equipment Manufacturer (OEM) bearings are produced by or for the same company that manufactured your forklift. These parts are designed to be exact replicas of the bearings originally installed on your truck, ensuring perfect compatibility and performance. Choosing an OEM forklift combined roller bearing guarantees that the component will meet all the precise engineering specifications, material grades, and heat treatment standards set by the forklift brand. This translates to predictable performance, optimal lifespan, and the assurance that the part will not void any existing warranties on newer equipment. The primary advantage is certainty; you know exactly what you are getting. However, this certainty comes at a premium cost. OEM parts are often significantly more expensive than their aftermarket counterparts, which can be a major consideration for businesses operating older forklifts or large fleets where budget constraints are a reality. The decision often hinges on whether the premium price is justified for your specific application and the criticality of the equipment.

- Guaranteed Compatibility: Designed specifically for your forklift model, ensuring a perfect fit.

- Assured Quality: Manufactured to strict original specifications for materials, tolerances, and durability.

- Warranty Protection: Typically comes with a robust warranty and does not risk voiding the forklift's existing warranty.

- Peace of Mind: Reduces the risk of installation issues and premature failure, supporting a reliable forklift bearing solution.

Aftermarket Forklift Bearings: The Cost-Effective Alternative

Aftermarket bearings are produced by third-party companies not affiliated with the original forklift manufacturer. The aftermarket sector is vast, ranging from manufacturers producing high-quality parts that meet or exceed OEM standards to those producing inferior, low-cost copies. The main attraction of aftermarket forklift roller bearing parts is their lower price point, which can result in substantial savings, especially for large fleets. Many reputable aftermarket brands invest heavily in research and development to produce high-performance bearings using advanced materials and processes. However, the market's variability is its biggest drawback. Quality can be inconsistent, and without due diligence, you might purchase a bearing that fails prematurely, leading to more frequent replacements and higher long-term costs. Furthermore, while many offer warranties, the claims process might be more cumbersome than with an OEM distributor. Selecting a trusted aftermarket supplier is therefore paramount to a successful outcome.

- Cost Savings: Generally the most affordable upfront option for forklift bearing replacement cost management.

- Variety and Availability: A wide range of options from numerous suppliers, often readily available.

- Performance Spectrum: Quality varies from sub-par to superior; some brands may offer enhancements over OEM.

- Supplier Diligence: Requires research to identify reputable manufacturers that provide reliable quality and good warranty terms.

OEM vs. Aftermarket: A Detailed Comparison Table

To effectively weigh the pros and cons of OEM and aftermarket forklift combined roller bearing options, a side-by-side comparison of key decision-making factors is essential. This table breaks down the critical attributes, providing a clear, at-a-glance overview of what each option typically offers. It is important to remember that the "Aftermarket" column represents a range of possibilities, and the actual value offered will depend heavily on the specific brand chosen. This comparison assumes a tier-1, high-quality aftermarket part versus the genuine OEM component. The goal is to highlight the inherent trade-offs between the guaranteed consistency of OEM and the potential value (or risk) of the aftermarket path, helping you align your choice with your operational priorities and budget.

| Factor | OEM Bearing | Aftermarket Bearing |

| Price | Higher upfront cost | Lower upfront cost |

| Quality & Materials | Consistently high, to original specs | Variable (can be low to very high) |

| Fit & Compatibility | Guaranteed perfect fit | Usually good, but requires verification |

| Warranty | Comprehensive and straightforward | Varies by supplier; may be shorter |

| Availability | Through dealer networks | Widely available from many distributors |

| Long-Term Value | Predictable lifespan, higher cost | Risk of shorter lifespan, potential for high value |

How to Choose the Right Option for Your Fleet

There is no one-size-fits-all answer to the OEM vs. aftermarket debate for forklift mast roller bearing replacement. The optimal choice depends on a strategic analysis of your specific situation. Consider the age and value of the forklift: for a newer, still-under-warranty machine, OEM is almost always the recommended choice to protect your investment. For an older forklift nearing the end of its service life, a high-quality aftermarket part can be a perfectly rational and cost-effective solution. Evaluate the criticality of the application: a bearing on a forklift used intensively in a high-capacity, multi-shift environment might justify the OEM premium for maximum reliability. Conversely, a truck used for light, occasional duties might be a candidate for a trusted aftermarket brand. Finally, assess your internal maintenance capabilities. If your team can thoroughly vet aftermarket suppliers and handle potential fitment issues, that path becomes more viable. The key is to make a conscious, informed decision rather than defaulting to the cheapest option.

- Forklift Age & Value: Newer/high-value trucks lean OEM; older trucks lean aftermarket.

- Operational Criticality: High-intensity, critical applications justify the OEM investment for reliability.

- Budget Constraints: Aftermarket offers immediate cost relief, but evaluate Total Cost of Ownership (TCO).

- Supplier Verification: For aftermarket, only purchase from reputable suppliers with positive reviews and clear warranties.

- Technical Support: Consider the level of technical support available from the parts supplier during installation.

FAQ

What are the symptoms of a failing combined roller bearing?

The most common symptoms of a failing forklift combined roller bearing are auditory and operational. You will often hear unusual noises first, specifically a loud grinding, rumbling, or popping sound, often referred to as forklift mast bearing noise, when extending, retracting, or tilting the mast. Operationally, you may notice increased play or wobble in the mast, making it difficult to position loads precisely. The mast may also tilt unevenly or jerk during operation instead of moving smoothly. In severe cases, visible damage or metal shavings around the mast channel may be present. Ignoring these signs can lead to complete bearing seizure, damaging the mast rails and resulting in a far more expensive repair.

Can I replace a combined roller bearing myself?

Replacing a combined roller bearing assembly is a complex and potentially dangerous task that should generally be left to trained and experienced technicians. The process requires safely supporting the mast assembly, which is extremely heavy, often using specialized tools to disassemble the mast sections. Incorrect disassembly or reassembly can lead to mast failure, causing severe injury or damage. Furthermore, proper installation requires precise torque specifications and alignment to ensure the new bearing functions correctly and does not fail prematurely. While a highly skilled maintenance professional with the correct tools and service manual may attempt it, for most businesses, outsourcing this job to a certified technician is the safest and most reliable choice.

Is an aftermarket bearing as reliable as an OEM part?

The reliability of an aftermarket forklift roller bearing part is entirely dependent on the manufacturer. Reputable aftermarket brands produce bearings that meet or even exceed OEM specifications, using high-quality materials and rigorous quality control. These can be just as reliable as OEM parts and offer excellent value. However, the aftermarket space also contains low-quality manufacturers whose products may use inferior steel, have inadequate heat treatment, or suffer from imprecise machining. These bearings will likely have a shorter lifespan and could fail prematurely. The key is to conduct thorough research, choose a well-established and reviewed aftermarket brand, and perhaps even start with a trial on a less critical piece of equipment to validate its performance before a wider rollout.

How can I reduce the frequency of bearing replacements?

Preventative maintenance is the most effective strategy to extend the life of your forklift combined roller bearing and reduce replacement frequency. Implement a regular inspection schedule to check for early signs of wear, such as unusual noises or mast play. Keep the mast clean and free of dirt, grime, and debris, which are abrasive and can accelerate bearing wear. Ensure that the mast is properly lubricated according to the manufacturer's guidelines, as many modern mast designs require specific lubricants on the load-bearing surfaces. Finally, train operators to use the equipment smoothly, avoiding harsh, jerky movements, sudden drops, and overloading, all of which place excessive stress on the bearings and the entire mast structure.