Is your forklift struggling to lift loads smoothly? Are you hearing unusual noises from the mast? While many components contribute to the lifting mechanism, a worn-out or failing forklift sheave bearing is a common yet often overlooked culprit. This critical component ensures the smooth operation of the pulley system that raises and lowers the forks. Ignoring the early warning signs can lead to catastrophic mast failure, costly downtime, and significant repair bills. This comprehensive guide will delve into the role of the sheave bearing, how to identify problems, and the steps for proper maintenance and replacement, helping you keep your operations running safely and efficiently.

What is a Forklift Sheave Bearing and Why is it Critical?

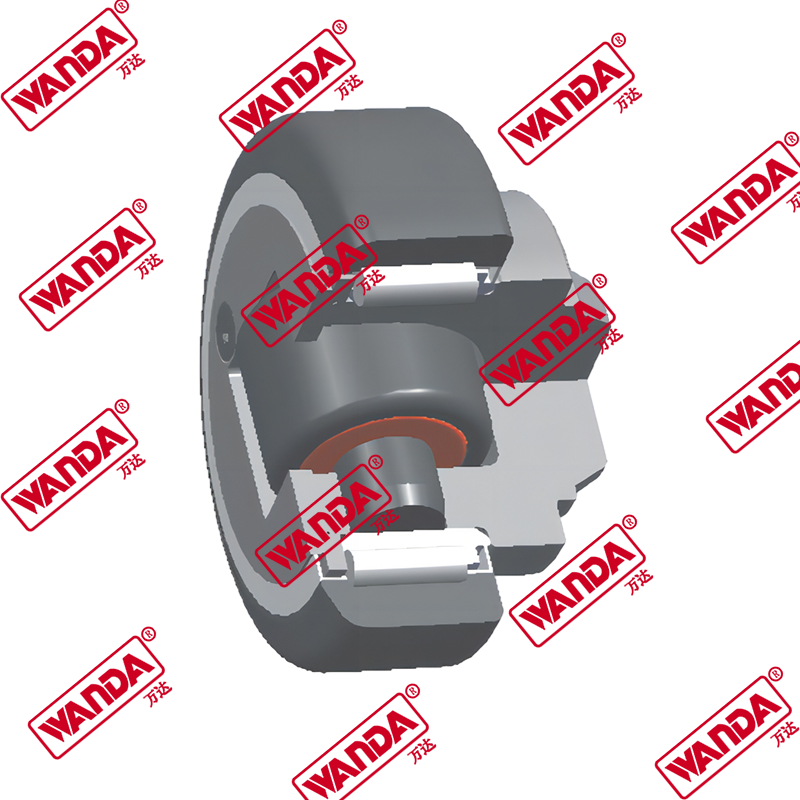

Located within the mast of a forklift, a forklift sheave bearing is a precision component that allows the sheave (or pulley) to rotate smoothly with minimal friction. The sheave guides the lift chain, which is directly responsible for raising and lowering the carriage and forks. The bearing withstands significant radial loads from the weight of the load and the tension of the chains. Its health is paramount to the entire lifting system's integrity. A failure in this small component doesn't just stop the lift; it can cause the chain to derail or snap, leading to a sudden drop of the load and potentially causing severe injury to personnel and damage to goods and equipment. Understanding its function is the first step in proactive maintenance, preventing the high costs associated with reactive repairs and unplanned operational halts.

- Function: Facilitates smooth rotation of the pulley, reducing friction and wear on the chain.

- Load Handling: Supports the immense weight of the load being lifted and the force from the hydraulic system.

- Precision Component: Manufactured to tight tolerances to ensure seamless operation within the mast assembly.

- Safety Role: Acts as a guardian of the lifting mechanism; its failure directly compromises operational safety.

Top 5 Symptoms of a Failing Forklift Sheave Bearing

Recognizing the early signs of a deteriorating forklift sheave bearing can save your business from expensive repairs and dangerous accidents. These symptoms often start subtly but gradually worsen as the bearing continues to degrade. Operators and maintenance personnel should be trained to identify these red flags during pre-operation inspections and daily use. Addressing these issues promptly not only ensures safety but also prevents collateral damage to other expensive mast components like the chains and the sheave itself. A proactive approach to these symptoms is a key aspect of a robust forklift maintenance program.

- Unusual Noises: Grinding, screeching, or rumbling sounds emanating from the mast during lifting or lowering operations are the most common indicators of a bearing that is lacking lubrication or has damaged rollers.

- Rough or Jerky Movement: The forks may hesitate, shudder, or move unevenly instead of lifting smoothly. This is caused by the bearing not rotating freely, creating inconsistent resistance.

- Decreased Lifting Capacity: The forklift may struggle to lift loads it previously handled with ease, as increased friction from the failing bearing robs the system of efficiency.

- Visible Wear or Damage: During inspection, you might see signs of excessive wear on forklift mast bearings, such as rust, pitting, metal flakes in the grease, or cracks in the bearing casing.

- Chain Misalignment: A severely worn bearing can cause the sheave to tilt, leading to the chain running off-track and wearing unevenly, which is a precursor to a chain derailment.

Step-by-Step Guide to Replacing a Forklift Sheave Bearing

Replacing a faulty forklift sheave bearing is a complex task that requires technical knowledge, the right tools, and a strict adherence to safety protocols. It is highly recommended that this procedure be performed by a certified technician. However, understanding the process provides valuable insight into the labor involved and underscores the importance of proper maintenance. The process involves securing the mast, relieving chain tension, and carefully disassembling components to access the bearing. Attempting this without proper training can lead to personal injury or further damage to the forklift.

- 1. Secure the Forklift and Mast: Park the forklift on a level surface, lower the forks completely, engage the parking brake, and block the wheels. Use certified mast props to securely hold the mast in place and prevent any accidental collapse.

- 2. Relieve Chain Tension: Carefully follow the manufacturer's manual to safely disengage and relieve tension from the lift chains. This is a critical safety step.

- 3. Remove the Sheave: Disassemble the necessary guards and components to gain access to the sheave assembly. Unbolt and remove the sheave from the mast.

- 4. Press Out the Old Bearing: Use a hydraulic press to push the old, damaged bearing out of the sheave. Ensure force is applied evenly to avoid damaging the sheave.

- 5. Press In the New Bearing: Clean the sheave housing thoroughly. Properly align the new bearing and use the press to install it squarely into place. Avoid hammering, as this can damage the new bearing.

- 6. Reassemble and Lubricate: Reinstall the sheave, reattach the chains following precise manufacturer specifications, and apply the recommended grease to the new bearing. Reassemble all guards and components.

- 7. Test Operation: Perform a series of test lifts without a load first, then with a partial load, to ensure smooth operation and verify there are no unusual noises.

How to Choose the Right Replacement Sheave Bearing

Selecting the correct replacement bearing is not a matter of guesswork. Installing an incorrect or substandard bearing can lead to premature failure and safety risks. The right choice depends on matching the exact specifications of your forklift's make, model, and mast type. Always prioritize quality and precision over price, as the cost of a bearing is negligible compared to the cost of downtime or an accident. Understanding the different types of mast bearings and their specifications is crucial for making an informed decision.

- Consult the OEM Manual: The forklift's official service manual provides the exact part number and specifications for the genuine OEM forklist sheave bearing.

- Match Bearing Numbers: The old bearing will have a part number etched or printed on it. Cross-reference this number with a reliable supplier to find a direct replacement.

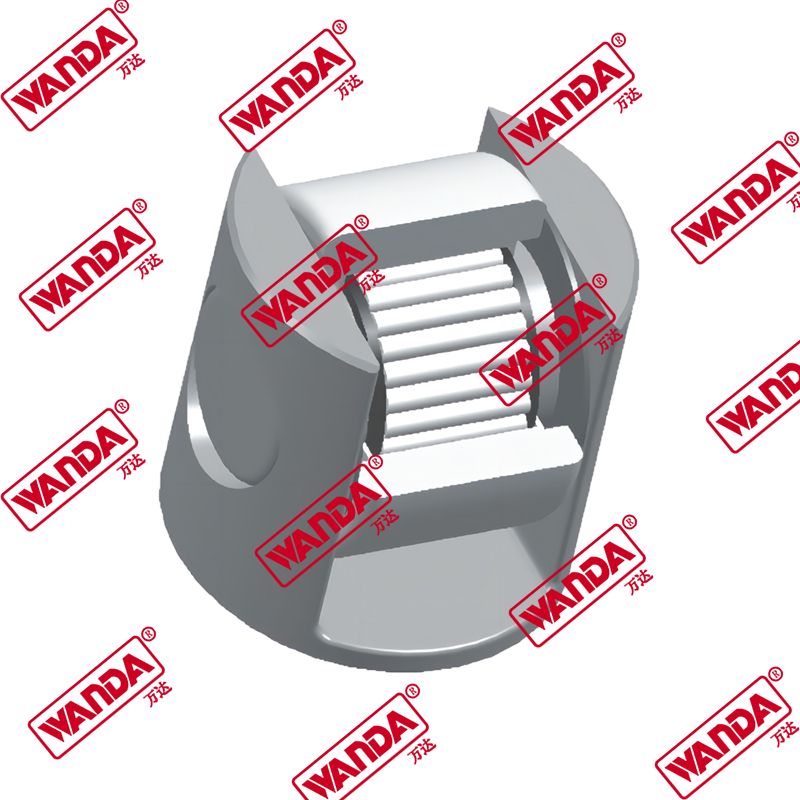

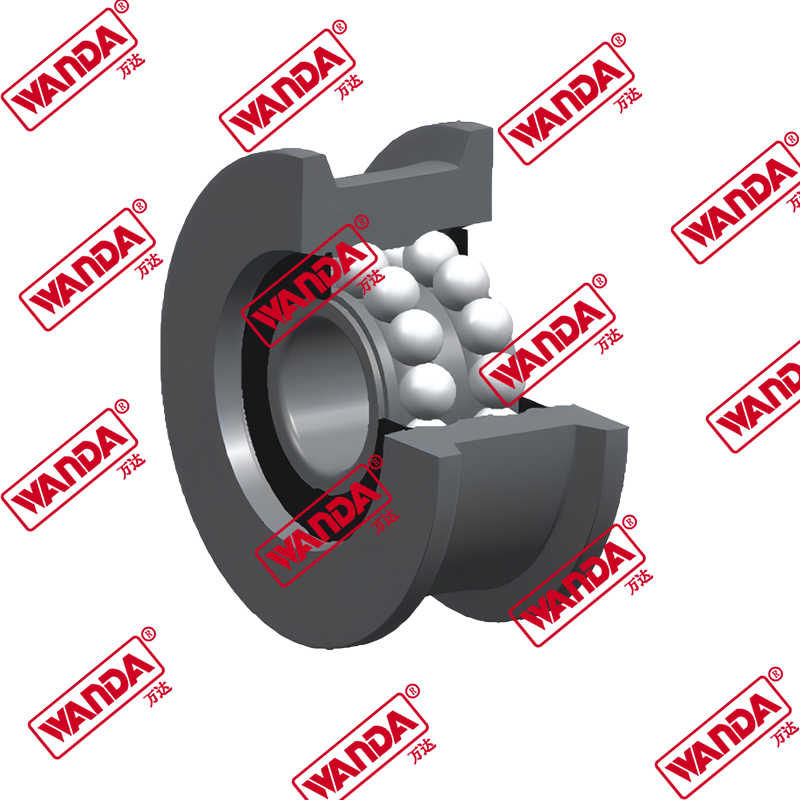

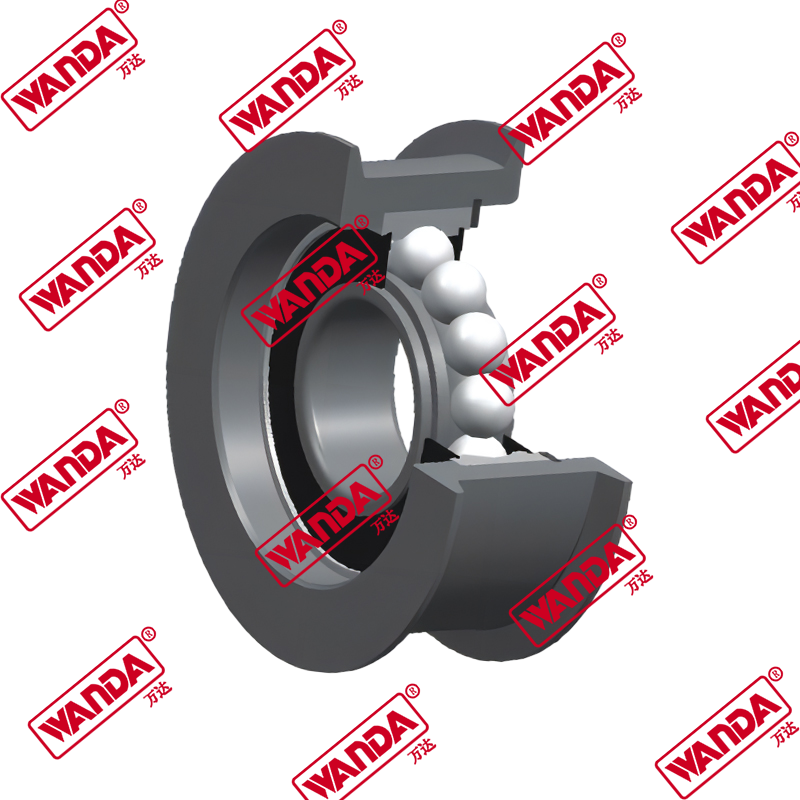

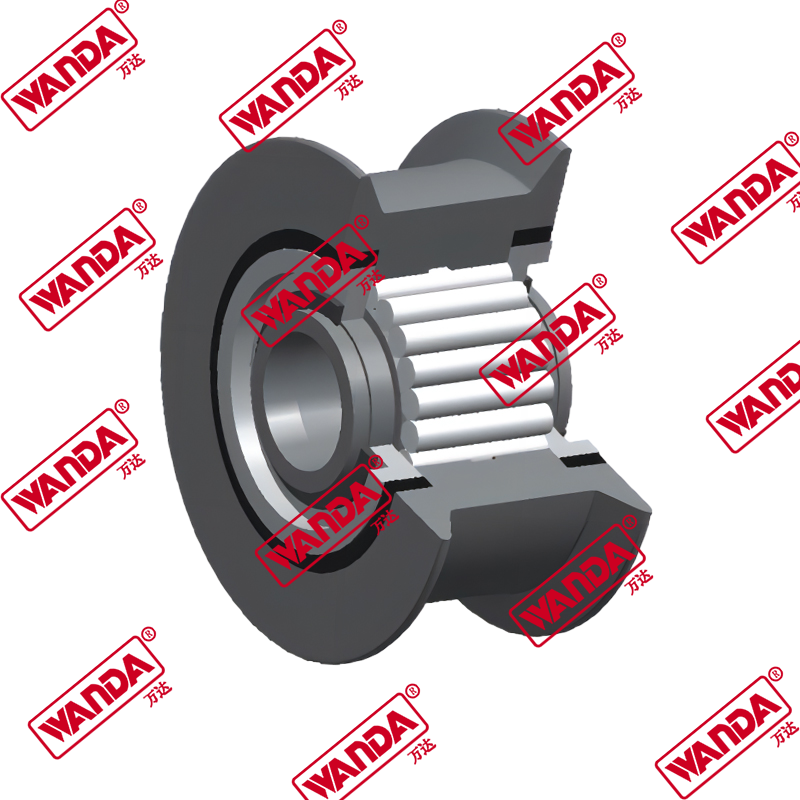

- Consider Bearing Type: Common types include ball bearings, roller bearings, and needle bearings. Each has specific load and application characteristics. Ensure the replacement matches the original type.

- Material and Seal Quality: Look for bearings made from high-grade chrome steel and featuring high-quality seals to keep contaminants out and grease in, especially in demanding environments.

| Selection Factor | Why It Matters | What to Look For |

| Part Number | Guarantees dimensional and load-capacity compatibility. | Match the OEM or cross-referenced number exactly. |

| Bearing Type | Determines performance under specific load types (radial vs. thrust). | Ball bearing for moderate loads, roller for heavier radial loads. |

| Seal Type | Protects internal components from debris and moisture. | Double-lip contact seals for harsh environments. |

| Material Grade | Affects durability, wear resistance, and service life. | Through-hardened high-carbon chromium steel. |

Proactive Maintenance Tips to Extend Sheave Bearing Life

Prevention is always cheaper than repair. A proactive maintenance regimen is the most effective strategy for maximizing the lifespan of your forklift sheave bearing and avoiding unexpected failures. This involves regular inspections, proper lubrication, and keeping detailed maintenance records. By integrating these checks into your daily and weekly routines, you can catch potential issues early, when they are still simple and inexpensive to address. This approach not only extends the life of the bearing but also contributes to the overall health and reliability of your entire forklift fleet.

- Regular Visual and Auditory Inspections: Train operators to listen for new noises and to report any irregularities in lifting performance immediately. Schedule weekly visual checks for signs of damage or wear.

- Proper Lubrication: Follow the manufacturer's schedule for forklift mast bearing lubrication. Use the specified type of grease and avoid over-greasing, which can attract dirt and cause damage.

- Keep the Mast Clean: Regularly clean the mast channels to prevent dirt, grit, and debris from entering the bearing seals and causing abrasive wear.

- Avoid Overloading and Shock Loads: Operate the forklift within its rated capacity and encourage smooth operation to prevent sudden impact loads that can brinell or crack bearing races.

- Maintain Detailed Records: Keep a log of all inspections, lubrication dates, and replacements for each forklift. This history is invaluable for predicting future maintenance needs.

FAQ

How often should I lubricate my forklift mast bearings?

The frequency of forklift mast bearing lubrication is not universal and depends heavily on the forklift's operating environment and manufacturer's guidelines. A common baseline recommendation is to lubricate every 200-250 operating hours or every three months, whichever comes first. However, if the forklift operates in extremely dusty, wet, or high-temperature conditions, this interval should be shortened significantly. The best practice is always to consult the specific lubrication schedule outlined in your forklift's owner's manual. Proper lubrication involves using a high-quality, recommended grease and applying it until old grease is purged from the seals, ensuring all old contaminants are removed.

Can I replace a forklift sheave bearing myself, or do I need a professional?

While it is technically possible for a skilled mechanic to replace a forklift sheave bearing, it is strongly recommended that this task be left to trained and certified professionals. The process involves working under significant stored energy in the lifted mast and tensioned chains, which presents a serious safety hazard if not handled correctly. Specialized tools like mast props and hydraulic presses are required. A professional technician will also ensure the bearing is pressed in correctly, aligned perfectly, and that the chain tension is set to precise manufacturer specifications, all of which are critical for safe operation and preventing immediate re-failure.

What is the average cost to replace a damaged sheave bearing?

The total cost to replace a damaged forklift sheave bearing can vary widely, typically ranging from \$500 to \$2,000+ USD. This cost is influenced by several factors: the cost of the bearing itself (OEM vs. aftermarket), the forklift model (common vs. rare parts), and the labor intensity of the job. Labor is usually the most significant factor, as the replacement process is time-consuming and requires skilled work. Additionally, if the bearing failure has caused collateral damage to the sheave, chains, or other mast components, the repair cost will increase substantially. This wide range underscores the value of preventive maintenance to avoid the cost altogether.

What's the difference between a sheave bearing and a regular ball bearing?

While a forklift sheave bearing may utilize ball or roller elements, it is far from a "regular" bearing. It is engineered as a specialized mast component for a very specific application. The key differences lie in its design, load capacity, and durability. Sheave bearings are built to withstand extreme radial loads from lifting heavy weights and are often designed with reinforced cages and special sealing systems to survive in the harsh, contaminant-filled environment of a forklift mast. A standard off-the-shelf ball bearing from a hardware store lacks these specialized features and would fail catastrophically and dangerously if used as a replacement, highlighting the critical importance of using the correct designated part.

Are there any specific noises that indicate a sheave bearing problem?

Yes, there are distinct auditory clues that often point to a forklift sheave bearing issue. The most common is a continuous grinding or growling noise that occurs specifically when the mast is raising or lowering a load. This sound is caused by damaged rolling elements (balls or rollers) moving roughly over pitted races. A high-pitched screeching or squealing noise often indicates a lack of lubrication, where metal is grinding directly on metal. It's crucial to investigate any new or unusual sound coming from the mast immediately. Catching these symptoms of bad forklift bearings early through auditory cues is a key diagnostic tool for maintenance teams.