Understanding the Role of a Forklift Chain Pulley

The forklift chain pulley is an indispensable component within the lifting mechanism of a forklift truck. It functions as the pivotal connection point between the hydraulic lift cylinder and the forks, translating the vertical force of the cylinder into the horizontal movement that raises or lowers the load. This seemingly simple device is subjected to immense stress and wear during operation, making its integrity paramount for both safety and efficiency. A failure in this component can lead to catastrophic downtime, costly repairs, and, most importantly, severe safety hazards. Therefore, a deep understanding of its function, the various types available, and the criticality of proper maintenance is essential for any operation relying on forklifts. This guide delves into the specifics of forklift chain pulleys, providing a comprehensive resource for selecting, maintaining, and troubleshooting this vital part.

Key Considerations for Selecting the Right Pulley

Choosing the correct chain pulley is not a one-size-fits-all endeavor. Several factors must be meticulously evaluated to ensure optimal performance and longevity. The wrong choice can lead to premature wear, chain derailment, and reduced lifting capacity.

Load Capacity and Compatibility

The most critical factor is matching the pulley's load capacity to the specific application and the forklift's rated capacity. Exceeding this capacity is extremely dangerous. Furthermore, compatibility with the existing chain is non-negotiable. The pulley's grooves must perfectly align with the chain's links to ensure smooth operation and prevent unnecessary friction.

- Always verify the manufacturer's specified load rating for the pulley.

- Cross-reference the chain size (e.g., 3/4", 1") with the pulley's designed chain size.

- Consider the duty cycle; high-intensity applications may require a pulley with a higher safety factor.

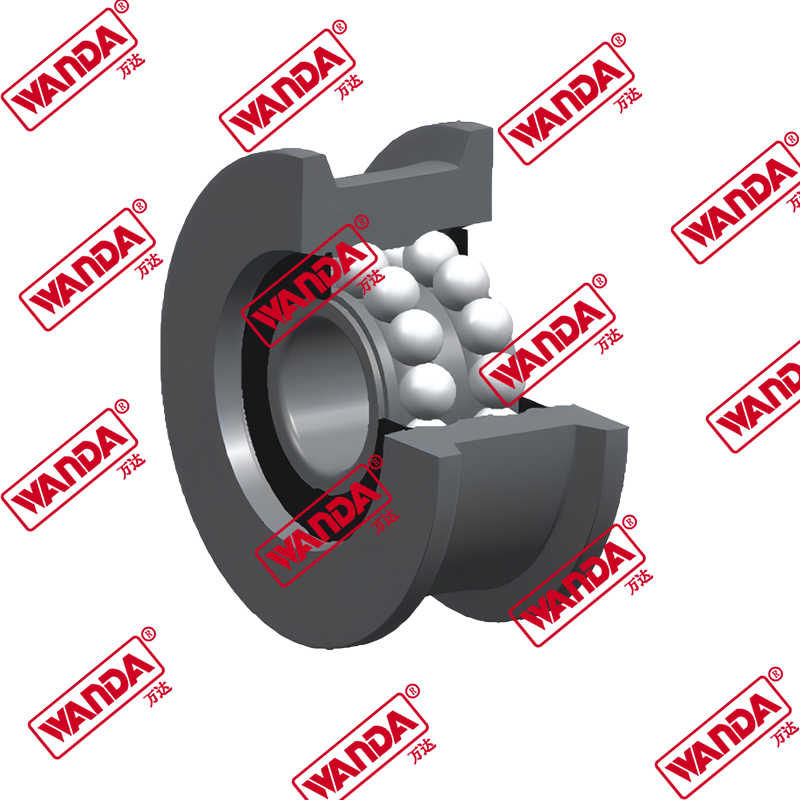

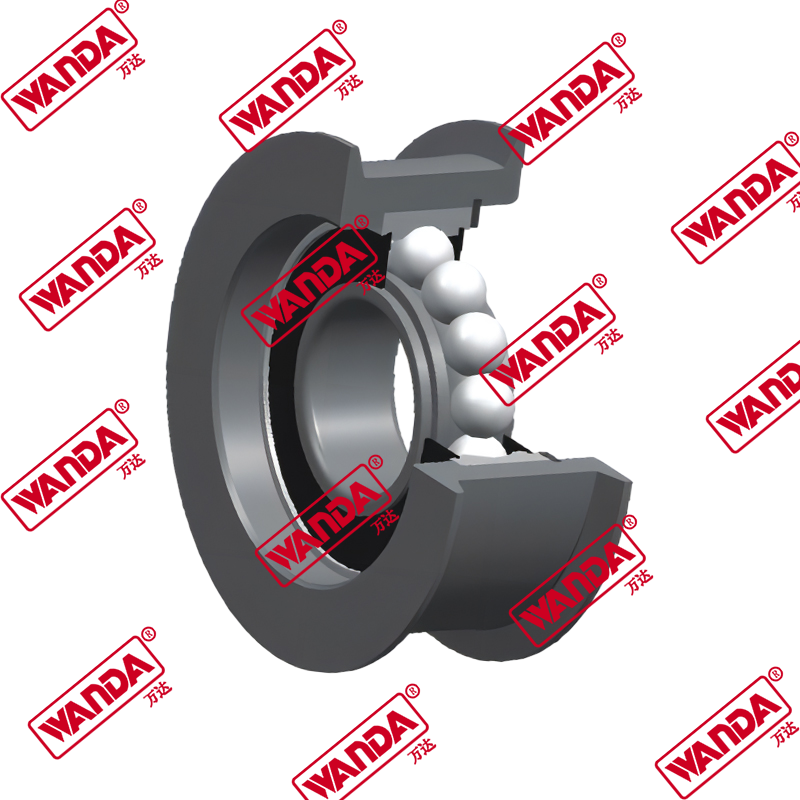

Material and Construction

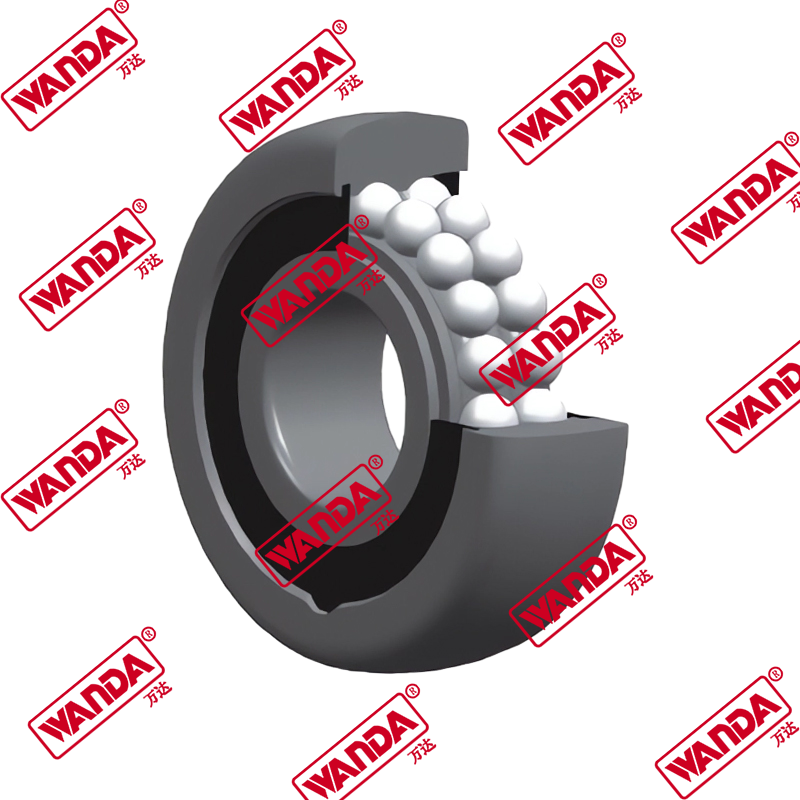

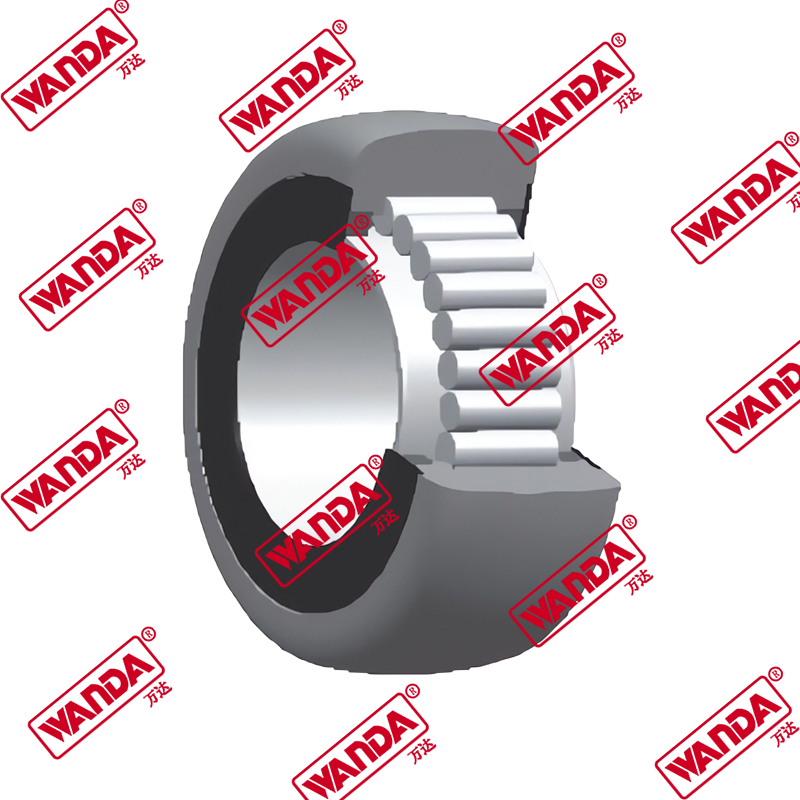

The material composition of the pulley directly influences its durability and suitability for certain environments. The two most common materials are forged steel and cast iron, each with distinct advantages.

Forged steel pulleys are created by heating and hammering steel into shape, resulting in a denser, stronger, and more impact-resistant product. They are ideal for high-capacity applications and harsh environments where shock loading is a possibility. Conversely, cast iron pulleys are made by pouring molten iron into a mold. While generally strong and wear-resistant, they can be more brittle and susceptible to cracking under extreme shock loads. The choice between forged and cast often comes down to the specific demands of the operational environment.

Essential Maintenance for Prolonging Pulley Life

Regular and proactive maintenance is the most effective strategy for maximizing the service life of your forklift chain pulley and ensuring operational safety. A neglected pulley can cause accelerated wear on the entire lifting assembly.

Routine Inspection Protocols

Implementing a scheduled inspection routine is paramount. This should be conducted by a trained technician and include a thorough examination for signs of wear and damage.

- Check for Wear: Look for visible grooves or a "hooked" appearance on the pulley sheaves. This indicates the chain has been grinding against the pulley, a common sign of misalignment or a worn-out chain.

- Crack Inspection: Visually inspect the entire pulley, especially the hub and between the sheaves, for any hairline cracks. A cracked pulley must be replaced immediately.

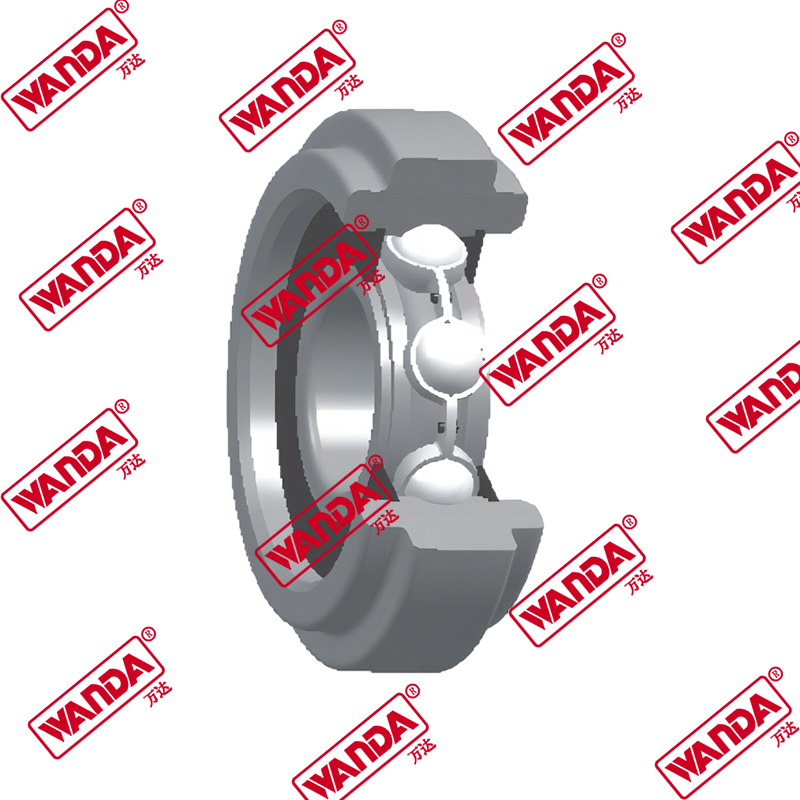

- Bearing Check: Spin the pulley by hand. It should rotate smoothly and quietly without any grinding, binding, or excessive play. Any roughness suggests bearing failure.

Lubrication and Cleaning

Proper lubrication reduces friction, minimizes wear, and protects against corrosion. However, the type of lubricant and frequency of application are crucial.

Use a lubricant specifically designed for heavy-duty chains and industrial equipment. Avoid over-lubrication, as excess grease can attract dirt and grime, creating an abrasive paste that accelerates wear. The pulley and chain should be cleaned periodically to remove built-up debris that can interfere with smooth operation and act as a grinding compound. The process of how to replace a forklift mast chain pulley often begins with a thorough cleaning of the surrounding area to prevent contamination during the repair.

Identifying and Troubleshooting Common Pulley Problems

Even with diligent maintenance, problems can arise. Recognizing the symptoms of a failing pulley early can prevent more extensive damage and costly downtime.

Symptoms of a Worn or Failing Pulley

Operators and maintenance personnel should be trained to identify the warning signs.

- Unusual noises during lifting/lowering, such as grinding, squealing, or popping sounds.

- Jerky or uneven movement of the forks.

- The mast struggling to lift a load that was previously within capacity.

- Visible metal shavings or flakes in the mast channel, indicating active wear.

These symptoms often point to issues like severe sheave wear, seized bearings, or misalignment. For instance, understanding the specifications for heavy duty forklift chain pulleys can help you diagnose whether an undersized pulley was incorrectly installed, leading to premature failure.

Addressing Chain and Pulley Misalignment

Misalignment is a primary cause of rapid wear on both the chain and the pulley. It occurs when the pulley is not perfectly parallel to the other sheaves in the system, causing the chain to rub against the sides of the pulley grooves.

Correcting misalignment typically requires adjusting the pulley's mounting position or checking for bent mast components. It is a precise task that often necessitates professional service. Ignoring misalignment will drastically shorten the life of these components and pose a significant safety risk. The benefits of using a heat treated forklift pulley include better resistance to the deformation that can sometimes contribute to alignment issues over time.

Comparing Common Forklift Chain Pulley Types

Selecting the right type of pulley involves understanding the different designs available and their respective advantages. The following comparison outlines the key differences between standard, sealed, and heavy-duty pulleys.

The primary differences between these pulley types lie in their construction, protection, and intended application. Standard pulleys are cost-effective for light to moderate use in clean environments. Sealed pulleys offer superior protection for challenging conditions, while heavy-duty pulleys are built to withstand the highest stresses and most intense duty cycles.

| Pulley Type | Key Features | Ideal Application | Considerations |

|---|---|---|---|

| Standard Pulley | Basic design, often with open bearings, made from cast or forged steel. | Light to moderate duty in warehouse and indoor settings. | Requires frequent lubrication and inspection; susceptible to contaminants. |

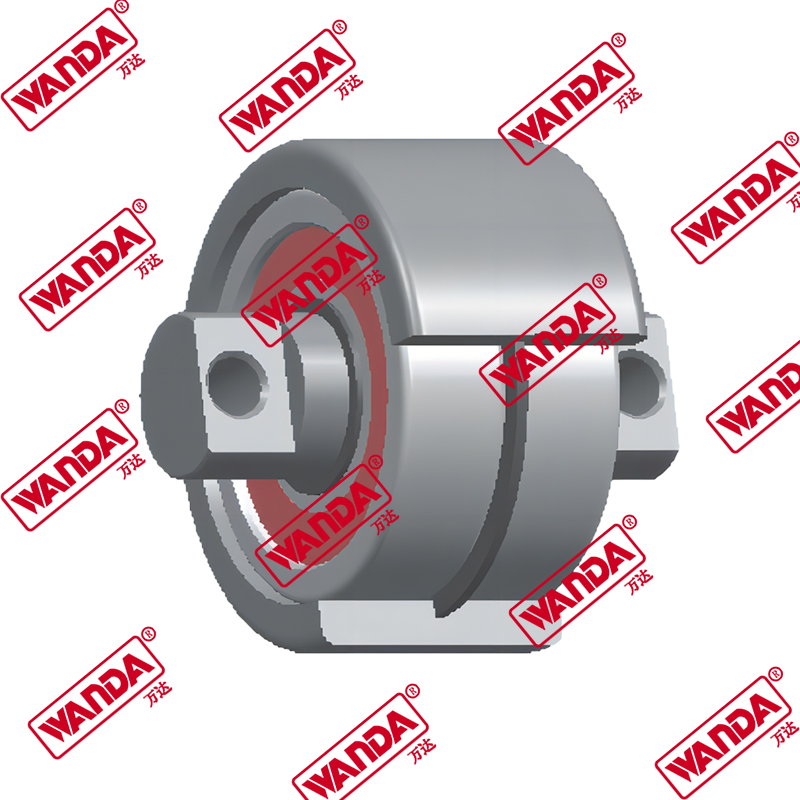

| Sealed Bearing Pulley | Equipped with seals to protect bearings from dust, moisture, and debris. | Environments with high dust, moisture, or chemical exposure. | Higher initial cost but reduced maintenance needs and longer life in harsh conditions. |

| Heavy-Duty/High-Capacity Pulley | Reinforced design, larger diameter, often forged from high-grade steel and heat-treated. | High-capacity forklifts, lumber, steel, and construction industries. | Designed to handle shock loads and continuous heavy use; premium price point. |

Ensuring Safety and Performance in Your Operations

The integrity of the forklift chain pulley is a cornerstone of warehouse and industrial safety. A proactive approach centered on correct selection, rigorous maintenance, and prompt troubleshooting is non-negotiable. Investing in high-quality components, like a heat treated forklift pulley, pays dividends in reduced downtime and enhanced safety. Furthermore, ensuring you have the correct specifications for heavy duty forklift chain pulleys for your specific equipment is a fundamental step that cannot be overlooked. Regular training for operators to recognize early signs of trouble, such as unusual noises or performance issues, creates a first line of defense. Ultimately, treating the chain pulley with the importance it deserves ensures not only the smooth running of your material handling operations but also protects your most valuable assets: your personnel and your equipment. Understanding the process for how to replace a forklift mast chain pulley is a critical part of any maintenance protocol, ensuring repairs are conducted safely and correctly when necessary.