The Critical Role of Forklift Combined Roller Bearings in Material Handling

In the demanding world of material handling and warehouse operations, equipment reliability directly impacts productivity and profitability. At the heart of many forklift mast systems lies a crucial component: the forklift combined roller bearing. This specialized bearing plays a pivotal role in ensuring smooth vertical movement of the mast while withstanding substantial radial and axial loads. Understanding the function, benefits, and maintenance requirements of these bearings can significantly extend equipment lifespan and minimize operational disruptions. This comprehensive guide explores how proper selection and maintenance of combined roller bearings can transform your maintenance strategy and deliver substantial operational benefits.

Five Essential Long-Tail Keywords for Bearing Optimization

To effectively address information needs in this specialized field, we've identified five strategic long-tail keywords that combine relevant search volume with manageable competition. These phrases represent specific queries that professionals use when seeking solutions to particular bearing-related challenges:

- forklift combined roller bearing installation guide

- replacement combined roller bearings for mast assembly

- heavy duty combined roller bearings specifications

- signs of worn out forklift mast bearings

- lubrication requirements for combined roller bearings

These keywords reflect the practical concerns of maintenance supervisors, equipment managers, and technicians responsible for keeping forklift fleets operational. By addressing these specific topics, we can provide targeted information that directly supports maintenance decision-making and troubleshooting processes.

Understanding Forklift Combined Roller Bearing Fundamentals

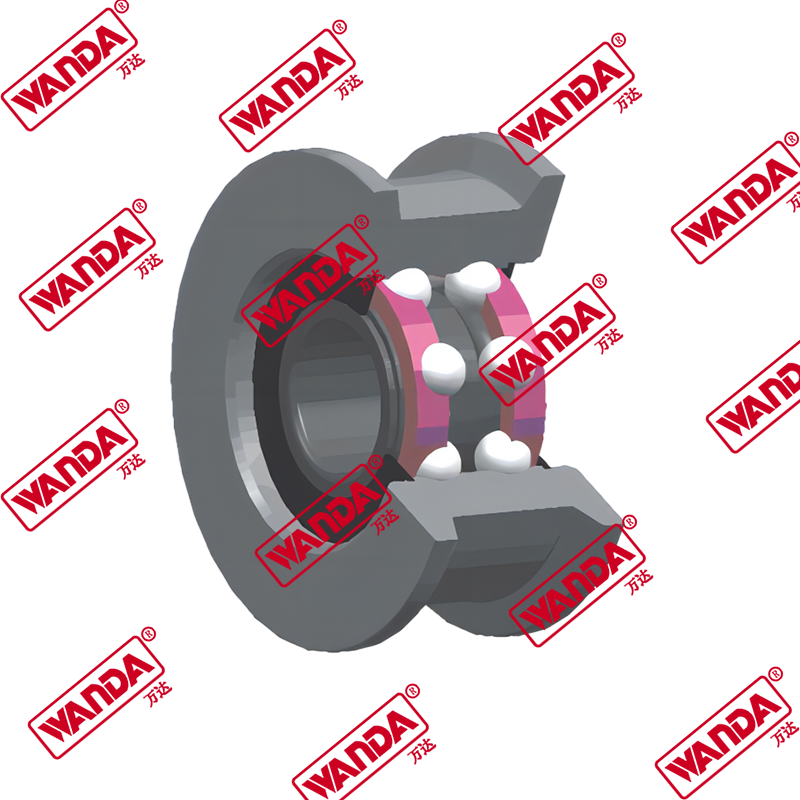

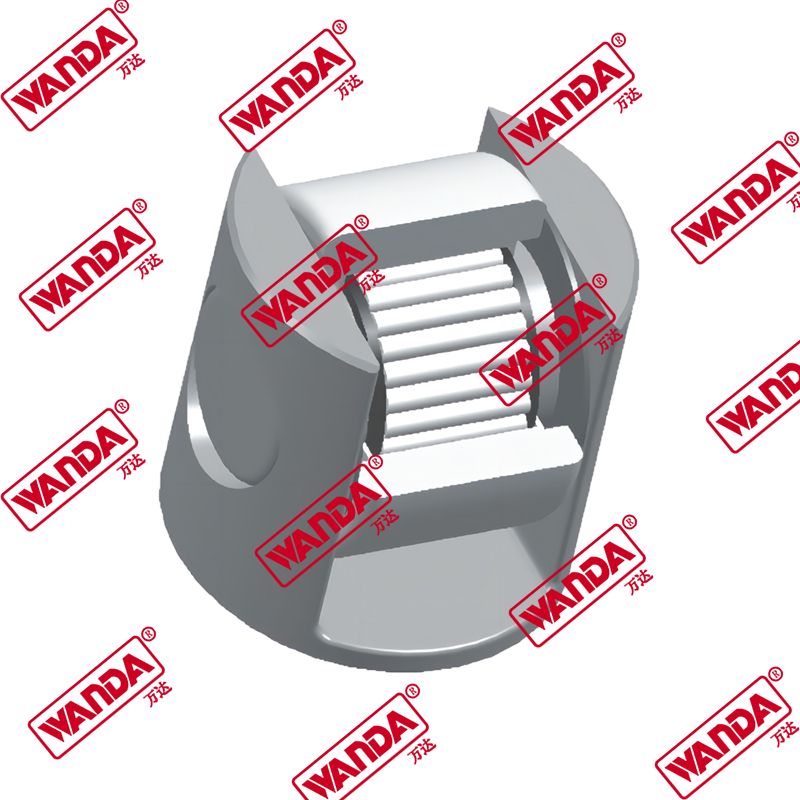

What Are Combined Roller Bearings and How Do They Function?

Forklift combined roller bearings represent an engineering solution specifically designed for the unique demands of material handling equipment. Unlike standard bearings that typically handle either radial or axial loads, combined roller bearings are precision-engineered to manage both types of forces simultaneously. This dual-capability makes them ideally suited for forklift mast applications where vertical movement (radial loads) and tilting forces (axial loads) constantly interact. The bearing's design incorporates two distinct raceways: one for radial rollers that support the mast's weight during lifting operations, and another for thrust rollers that absorb forces generated during load manipulation and mast tilting. This integrated approach eliminates the need for multiple bearing assemblies, simplifying mast design while enhancing overall reliability. The compact nature of these components allows for more efficient use of space within the mast structure, contributing to better visibility for operators without compromising lifting capacity or stability.

Key Advantages of Properly Maintained Combined Bearings

Investing in high-quality combined roller bearings and maintaining them properly delivers substantial operational benefits that extend far beyond simple component replacement. Well-functioning bearings contribute to smoother mast operation, reducing the jerky movements that can destabilize loads and create safety hazards. The precision engineering of these components ensures consistent performance across the entire lifting range, enabling operators to handle tasks with greater confidence and control. Additionally, properly lubricated and aligned bearings significantly reduce energy consumption by minimizing friction throughout the mast system. This efficiency gain translates to extended battery life in electric forklifts and reduced fuel consumption in internal combustion models. Perhaps most importantly, reliable bearings dramatically decrease the likelihood of catastrophic mast failure, which represents one of the most costly and disruptive incidents in material handling operations. The preventive approach to bearing maintenance ultimately preserves the entire mast structure by ensuring forces are properly distributed and absorbed.

Identifying Bearing Issues Before They Cause Downtime

Signs of Worn Out Forklift Mast Bearings

Recognizing the early indicators of bearing wear represents the first line of defense against unplanned downtime. Technicians and operators should remain vigilant for specific symptoms that signal developing bearing problems. Abnormal noises during operation often provide the earliest warnings, with grinding, popping, or crunching sounds suggesting compromised rolling elements or raceways. Visible mast misalignment or uneven movement during lifting and lowering sequences frequently indicates uneven bearing wear that requires immediate attention. Increased operational resistance, manifested as hesitant mast movement or uneven lifting speeds, typically points to lubrication breakdown or contamination. Excessive play or wobble in the mast structure when loads are elevated often signals advanced bearing wear that has created dangerous clearances. Operators may also report decreased lifting smoothness or a general degradation in forklift handling characteristics. Regular inspection protocols should specifically target these indicators, with documentation of any changes over time to establish wear patterns and predict remaining service life.

Diagnostic Procedures for Bearing Assessment

Implementing systematic diagnostic procedures enables maintenance teams to accurately assess bearing condition and plan interventions before failures occur. Visual inspection should examine bearing surfaces for scoring, pitting, discoloration from overheating, or visible deformation of rolling elements. Operational testing under controlled conditions helps identify performance deviations, with particular attention to startup characteristics and consistency across the lifting range. Measurement of mast clearances at multiple points provides quantitative data on wear progression, with comparisons to manufacturer specifications determining whether tolerances remain acceptable. Lubricant analysis can reveal contamination issues or breakdown of protective properties before visible symptoms emerge. For comprehensive assessment, disassembly inspection remains the definitive method for evaluating internal bearing condition, though this requires equipment downtime. The most effective maintenance programs combine multiple diagnostic approaches to build a complete picture of bearing health and anticipate replacement needs during planned maintenance windows rather than emergency repairs.

Selecting the Right Bearings for Your Application

Heavy Duty Combined Roller Bearings Specifications

Selecting appropriate bearings for specific operational requirements demands careful consideration of technical specifications and performance characteristics. Heavy-duty applications present particular challenges that standard bearings cannot adequately address, making specification understanding essential for optimal performance. Load capacity represents the most critical consideration, with dynamic load ratings indicating performance under operating conditions and static load ratings defining maximum capacity when stationary. Bearing dimensions must precisely match mast requirements, with even minor deviations potentially causing improper load distribution or accelerated wear. Material composition significantly influences durability, with case-hardened steel offering superior resistance to impact loads and deformation. Seal effectiveness determines contamination resistance, with multi-layer seals providing enhanced protection in demanding environments. Temperature tolerance becomes crucial in applications involving extreme ambient conditions or intensive operation cycles. The table below compares key specification considerations for standard versus heavy-duty combined roller bearings:

| Specification | Standard Bearings | Heavy-Duty Bearings |

|---|---|---|

| Dynamic Load Rating | Moderate (sufficient for light applications) | High (designed for intensive operation) |

| Impact Resistance | Limited protection against shock loads | Enhanced design for high-impact environments |

| Seal Configuration | Basic single-layer seals | Multi-layer, labyrinth-style seals |

| Material Hardness | Standard hardening processes | Deep case hardening for extended service life |

| Temperature Range | Standard industrial range | Extended range for extreme conditions |

Matching Bearing Capabilities to Operational Demands

Beyond basic specifications, successful bearing selection requires alignment with specific operational parameters and environmental conditions. Applications involving frequent heavy loads or rapid cycling demand bearings with enhanced dynamic capacity and superior heat dissipation characteristics. Environments with high contamination potential, such as lumber processing or recycling facilities, necessitate bearings with advanced sealing systems to exclude abrasive particles. Operations experiencing significant impact loads, common when handling irregular-shaped materials, benefit from bearings specifically engineered with increased radial clearance and tougher material compositions. Temperature extremes, whether from environmental conditions or intensive operation, require careful consideration of thermal expansion characteristics and lubricant compatibility. Operations with limited maintenance opportunities should prioritize bearings with extended lubrication intervals and superior contamination resistance. The most effective selection process involves documenting operational parameters, environmental challenges, and maintenance constraints before evaluating bearing options against these specific requirements rather than relying solely on generic specifications.

Proper Bearing Installation and Maintenance Protocols

Forklift Combined Roller Bearing Installation Guide

Correct installation procedures fundamentally influence bearing performance and service life. The process begins with comprehensive preparation, including verification of replacement part compatibility, inspection of mating components for wear or damage, and thorough cleaning of the work area to prevent contamination. Proper tool selection proves critical, with specialized bearing pullers, presses, and alignment tools ensuring controlled installation without component damage. The mounting surface requires meticulous preparation, with verification of dimensional accuracy and surface finish before proceeding. Bearing seating demands particular attention, with controlled pressure application ensuring square, gradual installation without cocking or binding. Post-installation verification should confirm free rotation without roughness or binding, proper axial and radial clearances, and correct alignment with mating components. The final step involves initial lubrication according to manufacturer specifications, ensuring immediate protection upon startup. Following methodical installation procedures prevents premature failures and establishes the foundation for extended service life, making this investment in proper technique one of the most valuable maintenance activities.

Lubrication Requirements for Combined Roller Bearings

Proper lubrication represents perhaps the single most important factor in maximizing combined roller bearing service life. The lubricant serves multiple essential functions: separating metal surfaces to minimize wear, dissipating heat generated during operation, protecting against corrosion, and excluding contaminants. Selecting the appropriate lubricant type requires consideration of operational speed, load characteristics, temperature range, and environmental conditions. Grease lubrication typically suits most forklift applications, offering simplified maintenance and effective contamination exclusion. However, specific formulations vary significantly in performance characteristics, with lithium-complex greases providing excellent all-around performance while synthetic options offer superior temperature resistance. Application frequency and quantity must balance sufficient lubrication with the risk of overheating from overfilling. The table below compares lubrication approaches for different operational conditions:

| Operational Condition | Recommended Lubricant Type | Application Frequency | Special Considerations |

|---|---|---|---|

| Standard Operation | Lithium-complex grease | According to manufacturer intervals | Monitor for consistency changes |

| High Temperature | Synthetic high-temperature grease | More frequent than standard | Watch for thermal breakdown |

| High Moisture | Calcium-sulfonate complex grease | Standard intervals | Enhanced corrosion protection |

| Heavy Load/Slow Speed | High-viscosity extreme pressure grease | Standard intervals | Enhanced film strength |

| Food Processing | NSF H1 registered synthetic grease | More frequent application | Reduced service life expectancy |

Implementing a Proactive Bearing Replacement Strategy

Replacement Combined Roller Bearings for Mast Assembly

Strategic replacement of combined roller bearings before failure occurs represents the most effective approach to minimizing unplanned downtime. Rather than waiting for obvious symptoms of complete bearing failure, proactive replacement during scheduled maintenance windows prevents the cascading damage that often occurs when bearings deteriorate during operation. Sourcing appropriate replacement bearings requires careful attention to specifications, with particular focus on dimensional accuracy, load ratings, and material quality. Compatibility with existing mast components proves essential, as even minor deviations can create improper loading patterns that accelerate wear throughout the system. When planning replacements, consider upgrading to bearings with enhanced features if operational demands have increased since original equipment selection. Proper inventory management ensures replacement availability when needed, particularly for older equipment where sourcing components might require longer lead times. Documentation of replacement dates, operating hours, and observed conditions establishes valuable historical data for refining future maintenance schedules and predicting bearing life under specific operational conditions.

Developing a Comprehensive Bearing Management Program

Transitioning from reactive repairs to proactive bearing management requires systematic planning and consistent implementation. An effective program begins with comprehensive equipment documentation, including bearing specifications, historical performance data, and failure records where available. Establishment of inspection protocols ensures consistent assessment across the equipment fleet, with standardized reporting facilitating trend analysis. Maintenance scheduling should integrate bearing inspection, lubrication, and replacement activities with other preventive maintenance tasks to minimize total downtime. Staff training ensures proper installation techniques, accurate diagnosis of developing issues, and consistent lubrication practices. Inventory management balances the cost of maintaining replacement bearings against the potentially substantial expense of unexpected downtime. Performance monitoring tracks key metrics including mean time between failures, bearing-related downtime costs, and maintenance labor requirements. The most successful programs continually refine their approach based on performance data, adapting inspection frequencies, lubrication schedules, and replacement thresholds to match actual operational conditions and bearing performance characteristics.

Maximizing Equipment Uptime Through Bearing Excellence

The strategic approach to forklift combined roller bearing selection, maintenance, and replacement delivers substantial operational benefits that directly impact productivity and profitability. By understanding bearing fundamentals, recognizing early warning signs of wear, implementing proper installation procedures, and maintaining optimal lubrication, equipment managers can dramatically extend component life and prevent unexpected failures. The comprehensive approach outlined—from initial specification review through proactive replacement planning—transforms bearings from potential failure points into reliability assets. Organizations that master these practices gain competitive advantage through increased equipment availability, reduced repair costs, and enhanced operational safety. The investment in bearing excellence returns multiplied benefits throughout the material handling operation, making this specialized knowledge genuinely valuable for maintenance professionals committed to operational excellence.