In the world of power transmission and material handling, the humble chain sheave plays a pivotal role. Often overlooked, this crucial component is essential for the smooth, efficient, and safe operation of countless industrial systems. This comprehensive guide delves into the intricacies of chain sheaves, exploring their function, types, selection criteria, and maintenance best practices. Whether you're an engineer specifying components or a maintenance professional ensuring operational continuity, understanding the nuances of chain sheaves is key to optimizing performance and longevity.

What is a Chain Sheave? Core Function and Design

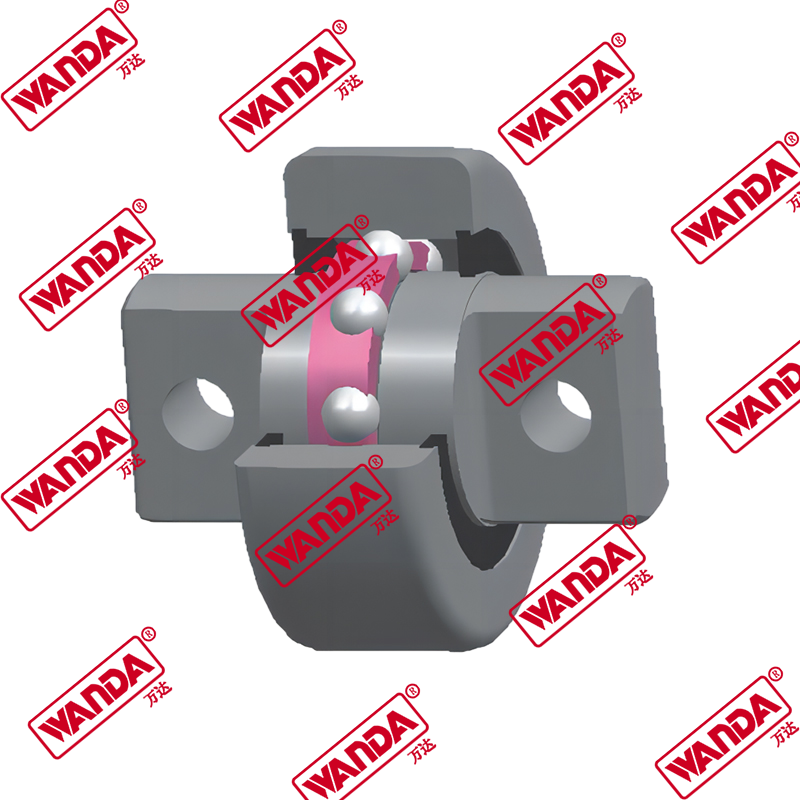

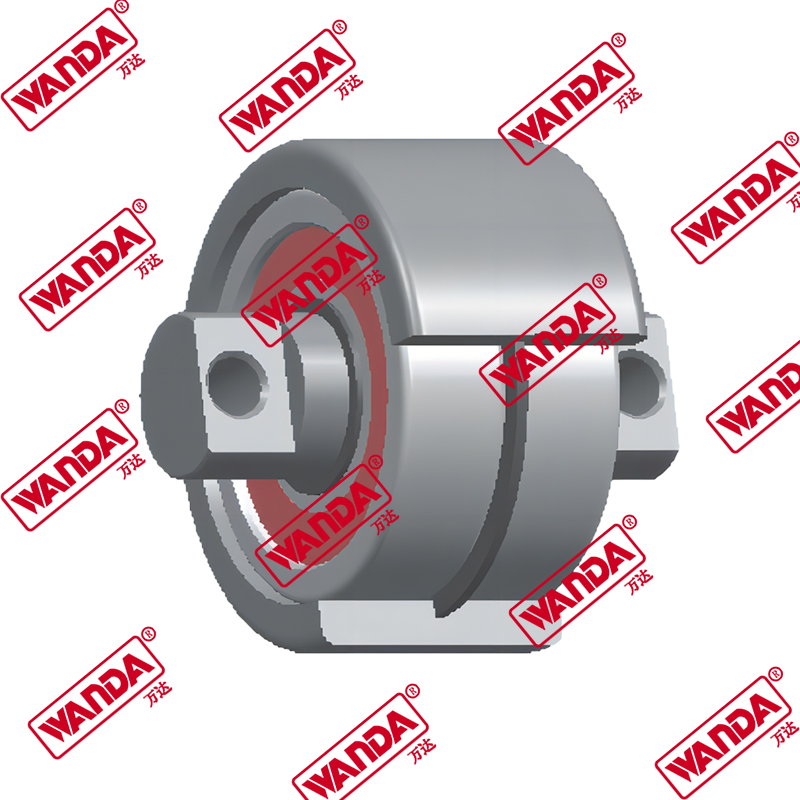

A chain sheave, commonly referred to in conjunction with pulley systems, is a wheel with a grooved rim designed to guide and support a chain. Its primary function is to change the direction of force or transmit power within a drive system while minimizing friction and wear on the chain links. Unlike gears that mesh with teeth, a sheave provides a track for the chain to run along, with the chain's rollers sitting in the groove.

Key Components and Materials

- The Groove: Precisely machined to match the chain's profile, ensuring proper seating and alignment.

- The Hub/Bore: The central hole that allows the sheave to be mounted on a shaft via a bushing, bearing, or direct fit.

- The Web/Plate: The body connecting the rim to the hub, designed for strength and sometimes weight reduction.

- Common Materials: Cast iron, ductile iron, steel, and sometimes engineered polymers, chosen based on load, environment, and required durability.

How to Choose the Right Chain Sheave Size and Pitch

Selecting the incorrect size or pitch is a leading cause of premature chain failure and system inefficiency. The chain pitch (the distance between pin centers) must perfectly match the sheave groove pitch.

- Step 1: Identify Chain Pitch: Measure the distance between three consecutive pins and divide by two for accuracy.

- Step 2: Match Sheave Specification: The sheave must be explicitly rated for that chain pitch (e.g., ANSI 40, 60, 80).

- Step 3: Determine Diameter: Larger sheave diameters reduce chain articulation and bending stress, enhancing life. Minimum recommended diameters are specified by chain manufacturers.

How to choose the right chain sheave for heavy load applications requires additional considerations. Beyond pitch, focus on material strength (e.g., high-grade steel), robust web design, and bearing capacity. For instance, the engineering teams at Jiangsu Wanda Special Bearing Co., Ltd leverage their provincial technology center to design sheaves that meet extreme load specifications, ensuring the groove profile maintains integrity under stress.

Difference Between a Chain Sheave and a Sprocket

This is a fundamental point of confusion. While both are wheels used with chains, their interaction differs significantly.

| Feature | Chain Sheave | Sprocket |

|---|---|---|

| Engagement | Guides and supports the chain; the chain rollers ride in the groove. | Drives the chain via positive engagement; teeth mesh with the chain links. |

| Primary Function | Change direction, provide support, take up slack (idler role). | Transmit torque and motion (driver role). |

| Design Focus | Groove profile, wear resistance, smooth operation. | Tooth form, precise pitch, strength for power transmission. |

| Common Analogy | Like a guide rail for a train. | Like a gear for a bike chain. |

Understanding this distinction is crucial for proper system design and troubleshooting.

Signs of Wear and When to Replace a Chain Sheave

Proactive maintenance prevents catastrophic failure. Regular inspection for these signs is essential:

- Groove Wear: The most common issue. Look for a "hooked" or widened groove profile, which allows the chain to sit too high or become misaligned.

- Cracking or Fractures: Check the web and rim for hairline cracks, especially in high-stress or impact applications.

- Bearing/Bore Wear: Excessive play between the sheave and its shaft leads to vibration and misalignment.

- Surface Pitting or Corrosion: Indicates material fatigue or unsuitable material for the environment.

Ignoring wear leads to rapid chain degradation. Common problems with conveyor chain sheaves and solutions often stem from such wear. A worn groove on a conveyor idler sheave causes the chain to "wander," leading to edge damage and potential derailment. The solution is a scheduled replacement program using sheaves made from wear-resistant materials.

Maintenance Tips for Long-Lasting Chain Sheaves

Extending sheave life is cost-effective and improves overall system reliability.

- Alignment is Paramount: Misaligned sheaves impose side loads, causing uneven wear. Use a straightedge or laser aligner.

- Proper Lubrication: While the chain needs lubrication, excess grease/dirt can accumulate in sheave grooves, acting as an abrasive. Keep grooves clean.

- Correct Tension: Over-tensioning increases bearing load and wear; under-tensioning causes slippage and chatter. Follow manufacturer specs.

- Regular Cleaning: Remove abrasive contaminants like sand, metal dust, and old, caked lubricant from the groove.

Following a disciplined maintenance schedule is the best practice for longevity.

Cost-Benefit Analysis: Standard vs. Custom Engineered Sheaves

The choice between off-the-shelf and custom sheaves depends on application demands.

| Consideration | Standard Sheave | Custom Engineered Chain Sheave |

|---|---|---|

| Lead Time & Cost | Lower cost, immediate availability. | Higher initial cost and longer lead time for design/manufacture. |

| Application Fit | Suitable for common, standard applications. | Optimized for unique loads, space constraints, harsh environments, or extreme duty cycles. |

| Performance | Adequate for general purposes. | Superior performance, efficiency, and lifespan in specific conditions. |

| Total Cost of Ownership | May be higher if failures are frequent. | Often lower due to reduced downtime, maintenance, and replacement frequency. |

For non-standard applications, a custom engineered chain sheave designed by specialists like Jiangsu Wanda Special Bearing Co., Ltd can provide a superior return on investment. Their engineering research center focuses on exploiting new products and functions, creating solutions where standard components fail.

Advanced Considerations and Industry Trends

The evolution of chain sheaves is intertwined with broader industrial advancements.

The Role of Precision Manufacturing in Sheave Performance

Tolerances matter. A precisely machined groove ensures even load distribution across the chain rollers. Advanced manufacturing techniques, such as CNC machining and robotic welding, allow for consistency and complex geometries unattainable with older methods. This precision directly correlates to reduced vibration and noise levels[1].

Material Science and Special Coatings

Beyond standard metals, developments in material science offer enhanced options.

- Through-Hardened Steels: Provide consistent hardness throughout the material, resisting deformation.

- Specialized Coatings: Treatments like nitriding or applying thin, dense chrome layers can dramatically increase surface hardness and corrosion resistance, a key factor for chain sheave applications in harsh environments such as mining, marine, or chemical processing.

Integration with Modern Bearing Technology

The sheave is only as good as its connection to the shaft. Integrating advanced bearing solutions is critical. Companies like Jiangsu Wanda Special Bearing Co., Ltd utilize their expertise in special bearing design to create integrated sheave-and-bearing assemblies. These units offer:

- Pre-lubricated and sealed designs for maintenance-free operation.

- Superior alignment and load-handling characteristics.

- Compact designs that save space and simplify installation.

Frequently Asked Questions (FAQ)

1. What is the main purpose of a chain sheave?

The primary purpose of a chain sheave is to guide and support a chain, typically changing its direction of travel in a power transmission or conveying system. It acts as an idler to maintain proper chain tension and alignment, reducing wear and ensuring smooth operation.

2. How often should I inspect my chain sheaves?

Inspection frequency depends on the operating environment and duty cycle. For critical or high-use applications, a visual inspection should be conducted weekly. A detailed inspection, including measuring groove wear and checking for cracks, should be part of a monthly or quarterly preventative maintenance schedule.

3. Can I use a chain sheave that has a slightly different pitch than my chain?

No. Using a mismatched pitch is one of the fastest ways to destroy both the chain and the sheave. It causes improper seating, extreme stress on chain links and rollers, and leads to rapid, catastrophic failure. Always ensure exact pitch compatibility.

4. What are the benefits of a custom-engineered sheave?

Custom sheaves offer optimized performance for specific challenges. Benefits can include extended service life in abrasive or corrosive settings, unique mounting solutions for space-constrained designs, weight reduction for dynamic systems, and integration with specialized bearings or seals.

5. How does material choice impact a sheave's performance in wet or corrosive conditions?

Material choice is critical. Cast iron may corrode quickly. Stainless steel offers excellent corrosion resistance but can be costlier. Ductile iron with a protective coating is a common balance. For severe conditions, engineered polymers or heavily coated metals are specified to prevent rust and material degradation, ensuring reliability[2].

The chain sheave is a deceptively simple component whose correct selection and maintenance are vital for system health. From understanding the difference between a chain sheave and a sprocket to recognizing signs of wear and when to replace a chain sheave, informed decisions prevent downtime and save costs. Whether opting for a standard model or investing in a custom engineered chain sheave for heavy load applications or harsh environments, partnering with a knowledgeable manufacturer with deep engineering resources is invaluable. With over five decades of expertise, Jiangsu Wanda Special Bearing Co., Ltd embodies the specialized knowledge and manufacturing capability required to deliver solutions that keep industry moving reliably and efficiently.

References

[1] Smith, J., & Patel, R. (2021). "The Impact of Machining Tolerances on Vibration in Power Transmission Systems." *Journal of Mechanical Design and Reliability*, 15(3), 45-52.

[2] International Council for Machinery Lubrication (ICML). (2020). *Guidelines for Component Selection in Corrosive Environments*. ICML Press.