For over five decades, Jiangsu Wanda special bearing Co.,Ltd has been at the forefront of precision engineering, specializing in the research and production of high-performance special bearings. Our commitment to innovation, supported by a provincial technology center and advanced production lines, drives us to understand the critical components our products serve. Among these, the chain sheave stands out as a fundamental yet vital element in countless power transmission and lifting systems. This guide delves deep into the world of chain sheaves, offering expert insights to help you optimize performance and durability in your applications.

Understanding the Chain Sheave: More Than Just a Wheel

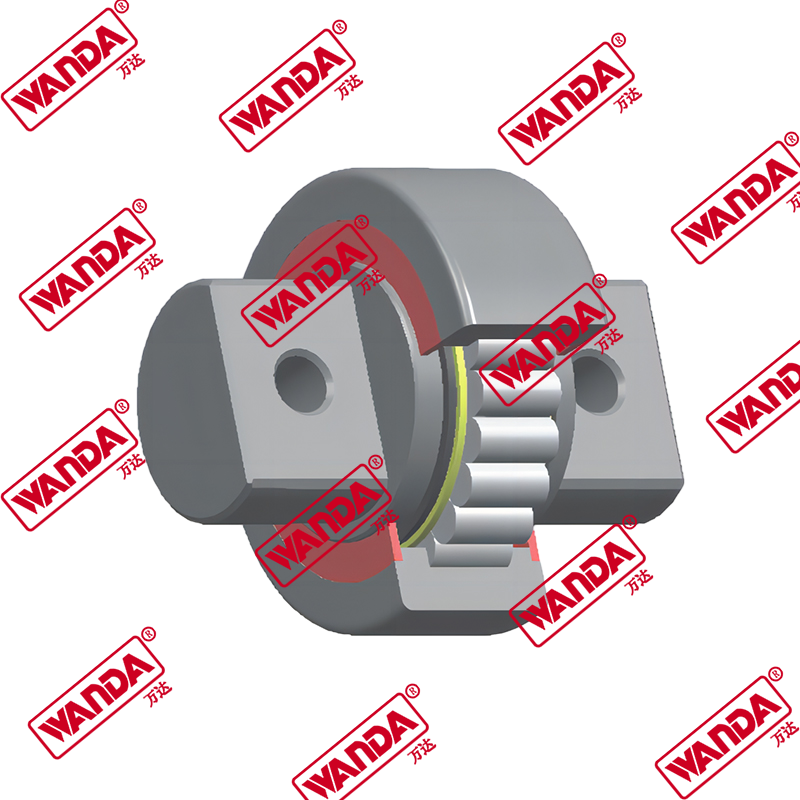

A chain sheave is a grooved wheel designed to guide and support a chain, ensuring efficient power transmission or load movement with minimal friction and wear. It is a cornerstone in systems ranging from industrial conveyors to complex lifting apparatus.

Core Components and Design Features

- Groove Profile: Precisely machined to match the chain's roller diameter and pitch, ensuring proper seating and engagement.

- Flange: Side rims that help keep the chain aligned on the sheave, preventing derailment.

- Bore & Hub: The central hole and surrounding structure that interfaces with the shaft, often incorporating keyways or locking mechanisms for secure mounting.

- Material & Construction: Typically made from high-strength materials like forged steel, ductile iron, or engineered polymers, chosen for durability and load capacity.

Selecting the Perfect Chain Sheave for Your System

Choosing the right sheave is paramount for system efficiency and longevity. An incorrect selection can lead to premature chain wear, increased energy consumption, and unexpected downtime.

Key Selection Criteria

Load Capacity and Chain Compatibility

The sheave must be rated for the system's maximum working load and dynamic forces. Calculating the load on a chain sheave involves considering the transmitted power, chain speed, and the angle of chain wrap. Incompatibility between chain and sheave pitch is a primary cause of rapid wear.

Material Considerations: Durability vs. Application

Material choice directly impacts performance. The difference between cast iron and forged steel sheaves is a critical decision point.

Forged steel sheaves offer superior tensile strength and impact resistance, making them ideal for high-load, high-shock environments like heavy lifting. Cast iron sheaves provide excellent wear resistance and vibration damping at a lower cost, suitable for steady-speed conveyor systems.

| Material | Key Advantages | Ideal Applications | Considerations |

|---|---|---|---|

| Forged Steel | High strength, good impact resistance, long fatigue life | Cranes, hoists, mining equipment, high-shock loads | Higher cost, typically heavier |

| Ductile Iron | Excellent strength-to-weight ratio, good wear resistance | Industrial drives, agricultural machinery | More brittle than forged steel under extreme impact |

| Cast Iron | Good wear properties, cost-effective, dampens vibration | Conveyors, low-speed drives, steady-state operations | Lower tensile strength, poor impact resistance |

| Engineered Polymers (e.g., Nylon) | Lightweight, corrosion-resistant, quiet operation | Food processing, packaging, clean environments | Lower load and temperature limits |

Specialized Sheave Types for Demanding Needs

For applications where standard sheaves fall short, specialized designs are essential. Selecting the right chain sheave for high-temperature applications requires materials that retain strength and resist thermal growth. Similarly, in corrosive environments like marine or chemical processing, understanding corrosion-resistant coatings for marine chain sheaves is crucial. These coatings, such as hot-dip galvanizing or specialized paints, form a barrier against moisture and salts, significantly extending service life.

Installation, Alignment, and Preventive Maintenance

Proper installation and routine care are as important as the initial selection. Misalignment is a leading cause of premature failure.

Step-by-Step Installation and Alignment

- Inspect Components: Check the sheave, shaft, and chain for any shipping damage or imperfections.

- Secure Mounting: Ensure the sheave is firmly seated on the shaft using the correct key and locking device. Avoid excessive force that could distort the bore.

- Precision Alignment: Use a straightedge or laser alignment tool to ensure the sheave is perfectly aligned with neighboring sprockets or sheaves. Proper maintenance tips for extending chain sheave life start with flawless alignment to prevent asymmetric wear.

- Tensioning: Apply the correct chain tension per manufacturer guidelines—neither too tight (causes bearing load) nor too loose (causes slippage and whip).

Developing a Proactive Maintenance Schedule

A consistent maintenance routine prevents costly failures.

- Visual Inspections: Regularly check for signs of wear, cracks, or deformation in the sheave groove.

- Lubrication: Follow a schedule to lubricate the sheave's bearing points, if applicable, to reduce friction.

- Chain & Sheave Wear Check: Measure chain elongation and inspect the sheave groove for hooking or grinding. Worn sheaves accelerate chain wear.

- Cleanliness: Keep sheaves free of abrasive debris and corrosive substances.

Troubleshooting Common Chain Sheave Problems

Recognizing early signs of trouble can save time and resources.

- Abnormal Noise (Squealing or Grinding): Often indicates misalignment, insufficient lubrication, or bearing failure.

- Rapid or Uneven Groove Wear: Caused by chain-sheave incompatibility, severe misalignment, or a worn chain running on a new sheave.

- Vibration: Can result from an unbalanced sheave, a bent shaft, or accumulated debris.

- Cracks or Fractures: Typically due to material defects, shock overloads, or extreme fatigue. Immediate replacement is necessary.

FAQs: Your Chain Sheave Questions Answered

1. How often should I inspect my chain sheaves?

We recommend a visual inspection during every routine machinery check (often weekly or monthly) and a detailed inspection with measurements at least every 500 operating hours or semi-annually, whichever comes first. Harsh environments demand more frequent checks.

2. Can I replace a chain without replacing the sheave?

It is not recommended. A worn sheave will quickly damage a new chain. Always inspect the sheave groove when replacing a chain. If wear is visible (e.g., a "hooked" groove profile), the sheave must be replaced concurrently to ensure system longevity.

3. What is the main cause of premature sheave wear?

The most common cause is misalignment between the sheave and the driving/driven components. Other major factors include using a chain with an incorrect pitch, over-tensioning, and operating in a dirty or corrosive environment without appropriate protection.

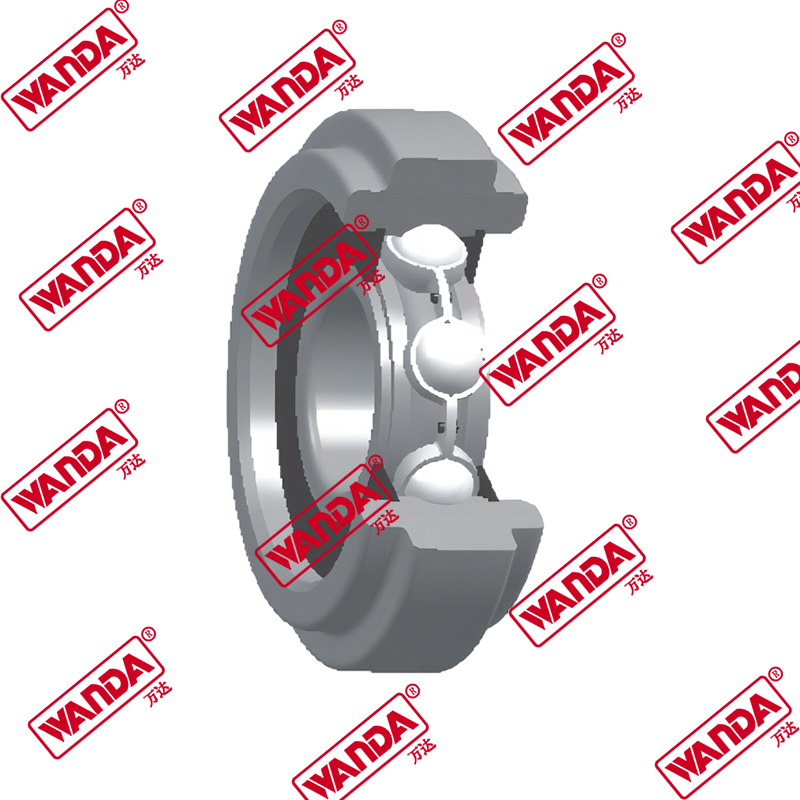

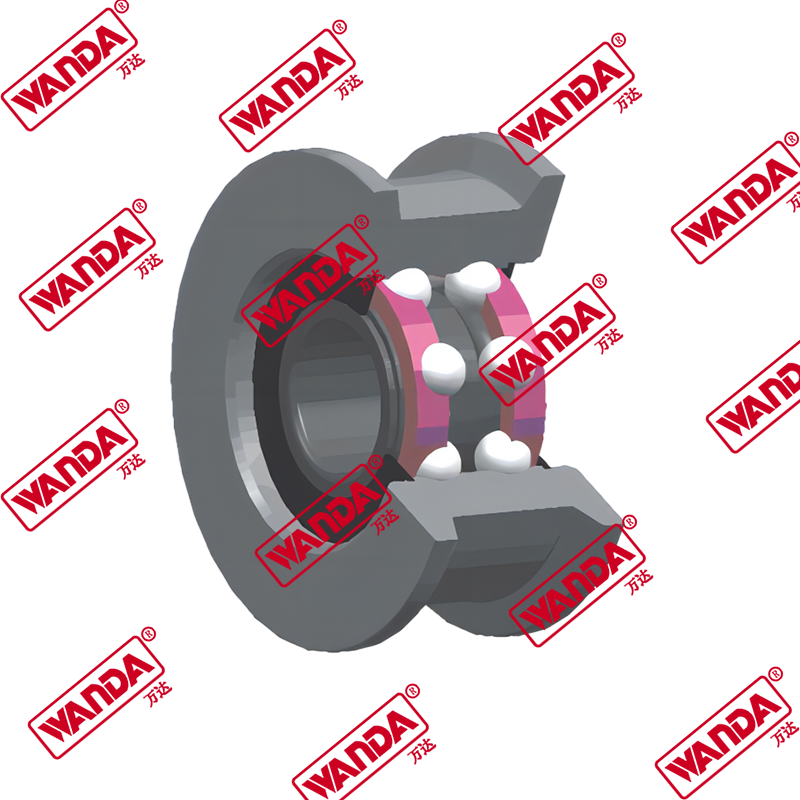

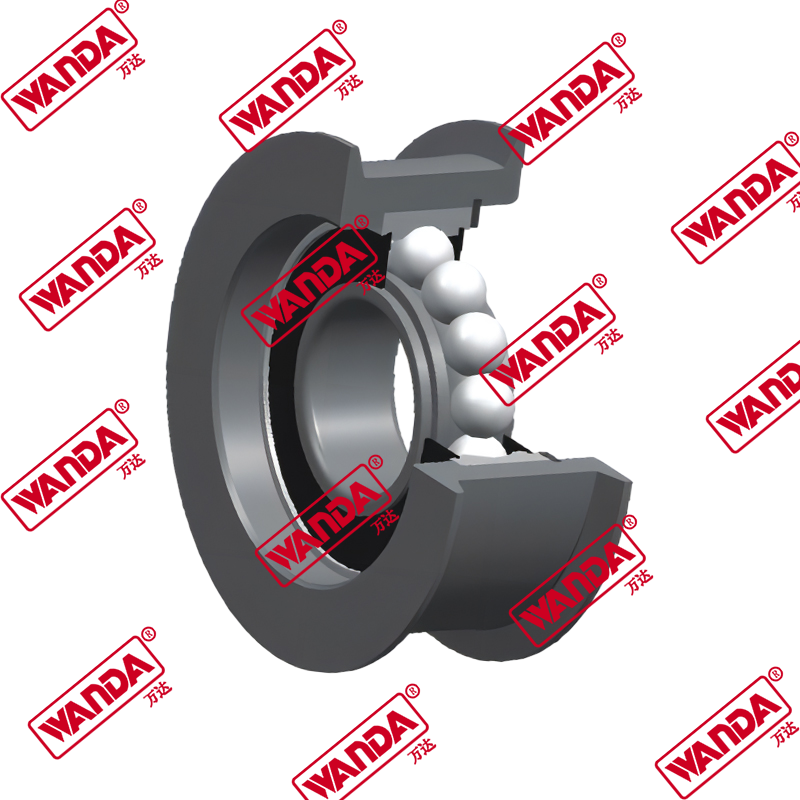

4. How do I choose between a sheave with a bushing and one with a bearing?

Bushed sheaves are simple, cost-effective, and suitable for low-speed, intermittent duty. Sheaves with integrated bearings (like ball or roller bearings) are designed for higher speeds, continuous operation, and heavier loads, as they significantly reduce rotational friction. The choice depends on your speed, load, and duty cycle requirements.

5. Are there industry standards for chain sheaves?

Yes. While specific to application, standards from organizations like the American Society of Mechanical Engineers (ASME) provide guidelines for dimensions, load ratings, and materials, especially for lifting and hoisting equipment. It is crucial to select sheaves that comply with relevant standards for your industry and application safety.

Conclusion: Partnering for Peak Performance

Selecting, installing, and maintaining the correct chain sheave is a precise science that directly impacts operational safety, efficiency, and cost. From understanding the critical difference between cast iron and forged steel sheaves to implementing maintenance tips for extending chain sheave life, every detail matters. For specialized challenges, such as calculating the load on a chain sheave in a unique configuration or specifying a chain sheave for high-temperature applications, expert consultation is invaluable. With decades of experience in precision bearing and component solutions, Jiangsu Wanda special bearing Co.,Ltd embodies the engineering excellence required to support these critical decisions, helping industries worldwide achieve reliable and enduring performance.