Introduction: Importance of Forklift Bearing Selection

Choosing the right Forklift Bearing is crucial for ensuring optimal performance and minimizing downtime in industrial forklift operations. As forklifts increasingly handle heavy loads and operate across multi-shift schedules, selecting a bearing that aligns with both operational demands and mechanical standards is essential. According to the latest report by Verified Market Reports, the global forklift bearing market is projected to reach a valuation of USD 1.9 billion by 2025, indicating strong growth driven by warehouse automation and industrial fleet expansion.

Source: Verified Market Reports

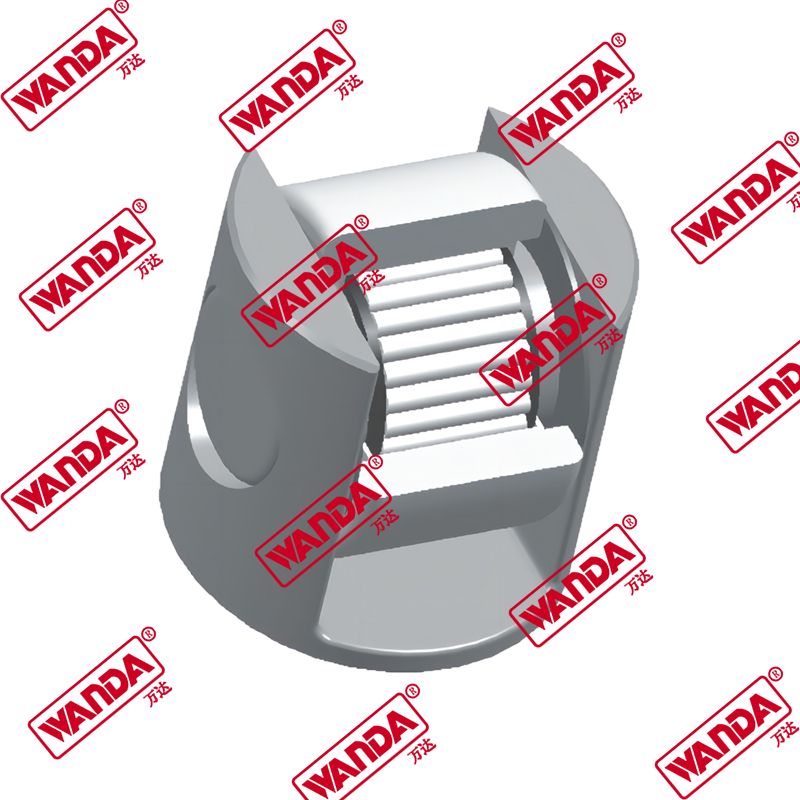

Established in 1969, Jiangsu Wanda Special Bearing Co., Ltd (Former Rugao Wanda Special Bearing Company) is a high-tech company dedicated to researching and producing special bearings. With advanced experimental equipment, top-notch production lines, and Provincial technology centers, we focus on designing bearings for industrial vehicles, developing new products, and drafting relevant technical standards. This foundation enables us to support B2B buyers and engineering teams in selecting the most suitable Forklift Bearing for their equipment.

Understanding Long-Term Performance Requirements

Load Capacity and Safety Margins

Accurate forklift bearing load capacity calculation is critical to ensure reliability under varying operational loads. Using standards such as ISO 281, engineers can determine the dynamic and static ratings of bearings and match them to forklift duty cycles. Additionally, ISO 17956:2025 offers guidance on evaluating static safety under tilt and misalignment, ensuring bearings can tolerate real-world conditions.

Source: ISO 281 & ISO 17956 Standards

Expected Bearing Life

Life prediction for bearings is a key consideration. The rolling bearing life prediction forklift methodology considers load, speed, lubrication, and environmental conditions to estimate service life. By integrating these calculations, engineers can optimize maintenance schedules and reduce unexpected failures, improving overall forklift uptime.

Key Technical Factors in Bearing Selection

Bearing Tolerance and Fit Considerations

Adhering to forklift bearing tolerance standards ensures that bearings perform consistently. Proper tolerance selection influences vibration, noise, heat generation, and overall mechanical efficiency. ISO 492 provides reference classes for bearing tolerance, enabling precise fitting to shafts and housings.

| Factor | High Precision Bearings | Standard Precision Bearings |

| Tolerance | ISO Class 2/4 (tight) | ISO Normal/6 (looser) |

| Application Suitability | High RPM & critical motion systems | General industrial conveyors & low RPM |

| Cost Implication | Higher | Lower |

Materials, Lubrication, and Environmental Factors

- Material hardness and fatigue life under combined radial/axial load

- Sealing systems to resist debris, moisture, and dust ingress

- Lubrication strategy: synthetic vs. mineral oils, critical for high-duty forklifts

- Temperature resistance and corrosion prevention in warehouse environments

Comparing Bearing Types for Forklift Applications

Forklifts utilize several bearing types depending on load and subsystem requirements. Tapered roller bearings are common in wheel hubs for high radial and axial loads, while deep groove ball bearings are used in lighter rotational elements. Needle roller bearings suit gearbox shafts where compact size and high load capacity are needed. Each bearing type presents trade-offs in performance, maintenance, and cost.

| Bearing Type | Typical Application | Performance Trait |

| Deep Groove Ball Bearing | Idle shafts & light rotation | Low friction, cost-effective |

| Tapered Roller Bearing | Wheel hub & high radial loads | High combined load capacity |

| Needle Roller Bearing | Gearbox intermediate shafts | Low profile, high load capacity |

Maintenance and Lifecycle Planning

Following an industrial forklift bearing maintenance schedule is vital for extending bearing life and preventing operational interruptions. Maintenance planning includes periodic lubrication, vibration monitoring, and inspection for wear. For heavy-duty environments, bearings may need more frequent checks to ensure longevity and reliability.

Heavy Load Environment Considerations

Selection for forklift bearing selection for heavy load environments requires evaluating load peaks, shock resistance, and thermal expansion. Bearings in these conditions should offer reinforced materials and optimized sealing to minimize failure risk under extreme duty cycles.

Selecting the right Forklift Bearing requires integrating load calculations, tolerance standards, lifecycle predictions, and maintenance planning. By leveraging industry standards and a data-driven approach, companies can reduce operational costs, enhance equipment reliability, and extend service life. With over 50 years of experience, Jiangsu Wanda Special Bearing Co., Ltd provides technical support and engineering insights to help B2B buyers make informed bearing decisions.

Frequently Asked Questions

- Q1: What criteria determine the best bearing for heavy-duty forklift use?

A1: Selecting the best bearing for heavy-duty forklifts requires considering load capacity, bearing type, tolerance, material hardness, and lubrication. Engineers often calculate forklift bearing load capacity calculation using ISO 281 standards to ensure the bearing can withstand peak radial and axial loads under operational conditions. Bearings designed for heavy-duty environments typically employ reinforced materials and robust sealing systems.

- Q2: How do industry standards affect forklift bearing selection?

A2: Industry standards provide a reference framework for performance, tolerance, and safety. For example, ISO 492 specifies bearing tolerance classes, while ISO 17956:2025 helps assess static safety under misalignment. Adhering to these standards ensures that selected Forklift Bearings meet operational requirements and reduce the risk of premature failure.

- Q3: What maintenance schedule maximizes bearing life?

A3: A structured industrial forklift bearing maintenance schedule includes periodic lubrication, vibration analysis, temperature monitoring, and inspection for wear. Bearings in high-load or harsh environments may require more frequent maintenance, while light-duty applications may allow longer intervals. Following these schedules improves service life and minimizes unexpected downtime.

- Q4: How does bearing clearance influence forklift performance?

A4: Bearing clearance affects friction, heat generation, noise, and load distribution. Tight clearance increases precision and reduces vibration but may raise operating temperatures, while loose clearance accommodates misalignment but can reduce efficiency. Evaluating forklift bearing tolerance standards ensures the proper fit for each shaft and housing.

- Q5: What are the differences between bearing types in forklift systems?

A5: Different bearing types serve specific functions in forklifts. Deep groove ball bearings are suitable for light rotation and low friction, tapered roller bearings handle high radial and axial loads in wheel hubs, and needle roller bearings provide compact solutions for gearbox shafts. Understanding the application environment helps in forklift bearing selection for heavy load environments and ensures optimal performance and lifespan.