The Unsung Hero of Material Handling: Forklift Chain Pulleys

At the heart of every forklift's lifting mechanism lies a critical yet often overlooked component: the chain pulley system. This assembly is far more than a simple wheel for a chain; it is a precision-engineered nexus where design decisions directly translate into operational performance, safety, and cost. The intricate relationship between the pulley's design characteristics and the forklift's ability to lift loads smoothly, hold them steady, and do so efficiently is a subject of profound importance for warehouse managers, maintenance engineers, and procurement specialists. A deep understanding of this relationship allows for better equipment selection, proactive maintenance, and optimized operational protocols. This article will dissect the key design elements of forklift chain pulleys, tracing their direct impact on two paramount metrics: load stability and lifting efficiency. We will explore how factors like material composition, groove geometry, bearing systems, and manufacturing tolerances create a ripple effect across the entire material handling process. By the end, you will recognize that the choice of a heavy duty forklift pulley replacement is not a mere maintenance task, but a strategic decision impacting your bottom line.

Decoding the Anatomy of a Forklift Chain Pulley

Before assessing impact, one must understand the components. A forklift chain pulley is a deceptively complex part designed to guide, support, and transmit force through the lift chain.

Core Components and Their Functions

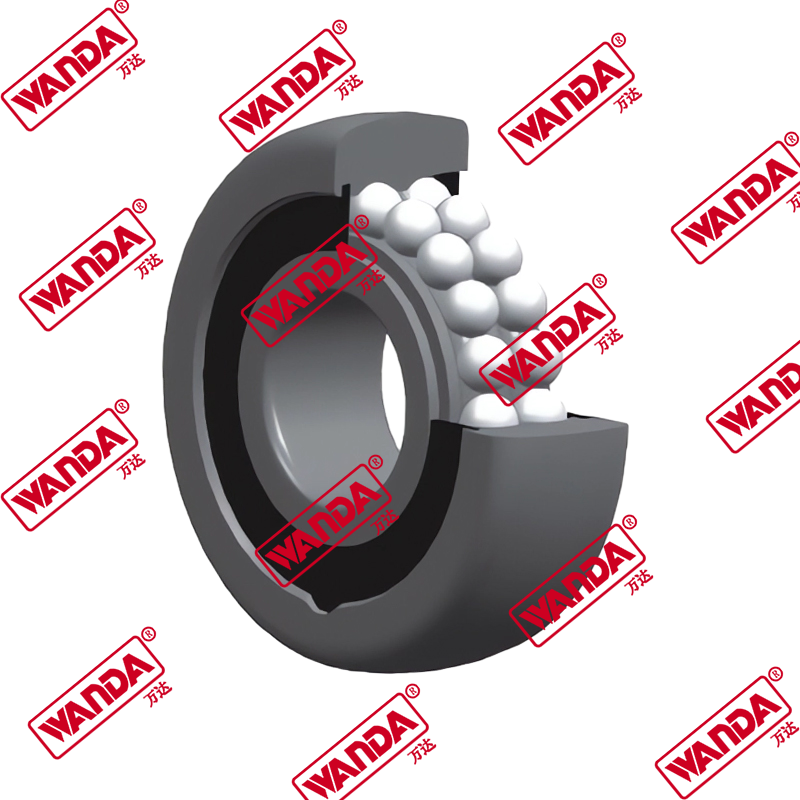

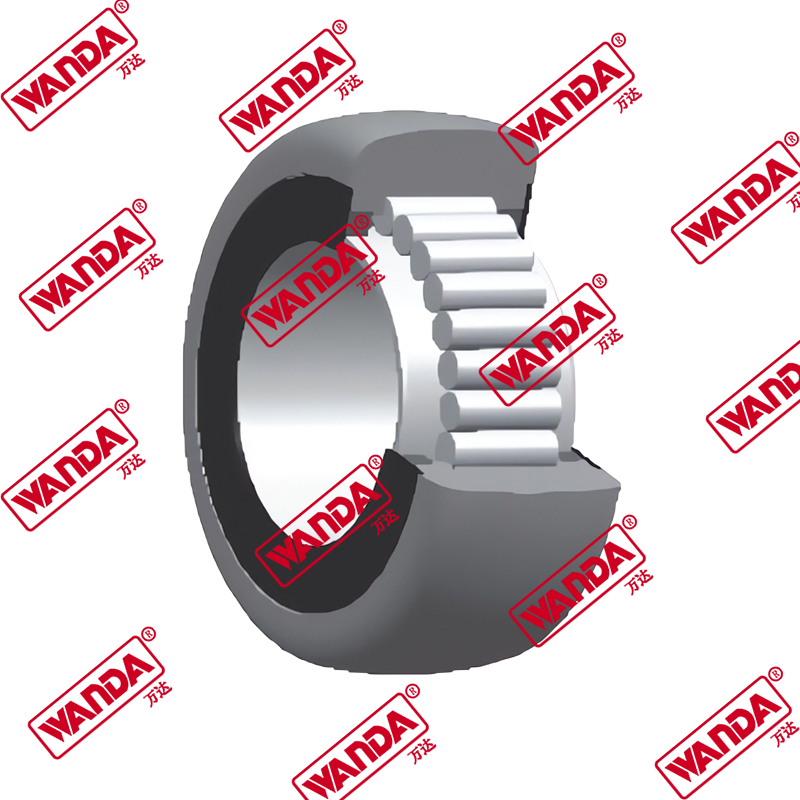

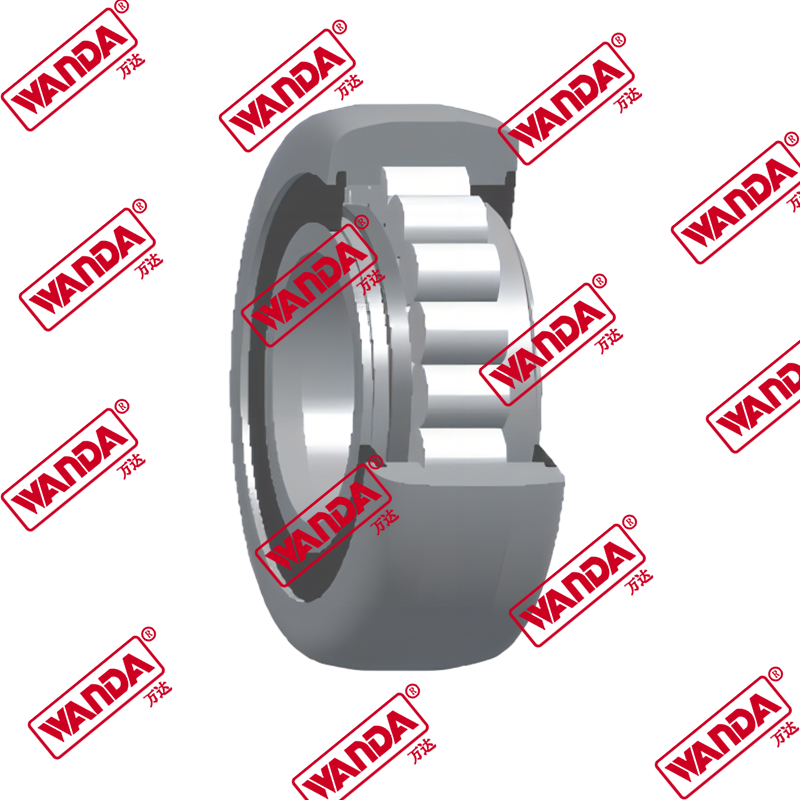

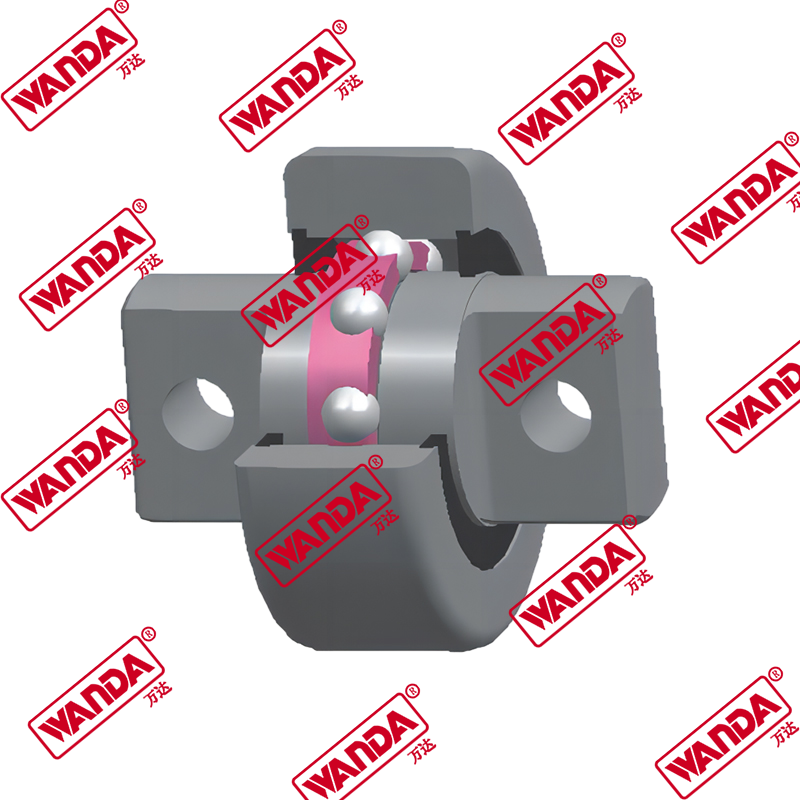

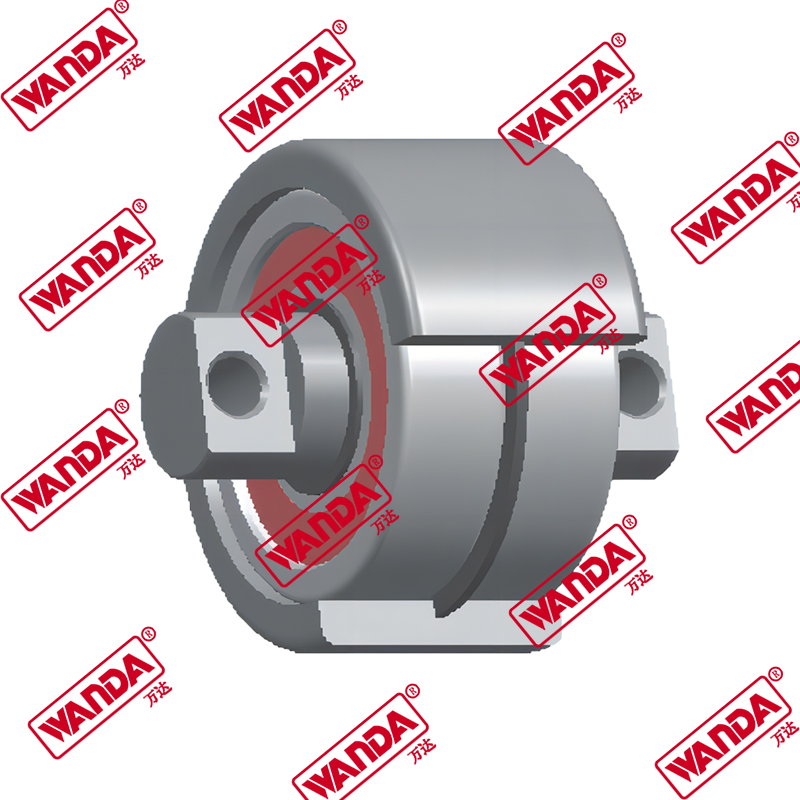

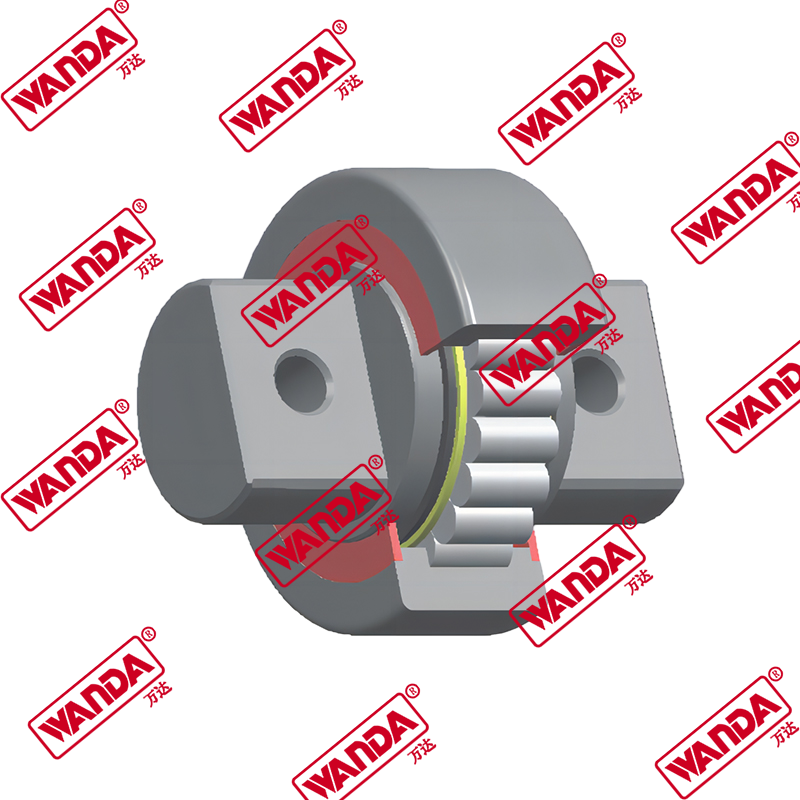

The primary elements include the sheave (the grooved wheel), the hub, the bearing assembly, and often a integrated guard or flange. The sheave's groove must precisely match the chain's profile to ensure proper seating and force distribution. The hub connects the sheave to the axle or mast, while the bearing system facilitates smooth rotation under immense radial and axial loads. Each of these components presents a series of design choices that collectively define the pulley's performance envelope.

Material Science in Pulley Construction

The selection of material is the first and most fundamental design decision. It dictates strength, wear resistance, weight, and ultimately, the lifespan of the pulley under specific operating conditions.

Forged Steel vs. Ductile Iron vs. Composite Polymers

Different materials offer distinct trade-offs between durability, cost, and performance. Forged steel pulleys provide the highest tensile strength and resistance to deformation under shock loads, making them ideal for high capacity forklift lifting systems. Ductile iron offers excellent wear resistance and good machinability at a potentially lower cost than forged steel, but may not handle extreme impact loads as well. Composite or polymer pulleys are lightweight and corrosion-resistant, reducing noise and chain wear, but they have lower temperature thresholds and load capacities. The choice must align with the forklift's duty cycle; a lumber yard handling uneven loads needs the robustness of forged steel, while a food processing plant might prioritize the corrosion resistance of composites.

The following table contrasts these material properties:

| Material | Key Advantages | Key Limitations | Ideal Application Context |

|---|---|---|---|

| Forged Steel | Exceptional tensile strength, high impact resistance, handles shock loads well. | Heavier, can be prone to corrosion if not coated, generally higher cost. | Extreme duty cycles, uneven loads (e.g., scrap metal, construction). |

| Ductile Iron | Excellent wear resistance, good machinability, good strength-to-weight ratio. | Less impact-resistant than forged steel, can be brittle in extreme cold. | General warehousing, manufacturing with consistent loads. |

| Composite/Polymer | Lightweight, corrosion-proof, reduces noise and chain wear, low maintenance. | Lower load capacity, sensitive to high temperatures and UV degradation. | Clean environments (food, pharmaceuticals), light-to-medium duty. |

The Direct Link Between Pulley Design and Load Stability

Load stability refers to the load's resistance to tilting, swaying, or shifting during lifting, lowering, and transport. A stable load is a safe load. The chain pulley is a primary contributor to this stability through its control of chain movement and tension.

Groove Profile Precision and Chain Engagement

The geometry of the pulley groove is paramount. A well-designed groove cradles the chain links securely, preventing lateral movement (side-to-side sway) and ensuring the force is transmitted axially along the chain. An imprecise or worn groove allows the chain to seat improperly, leading to micro-movements that amplify into visible load sway, especially when the mast is extended. This is why a wear-resistant forklift pulley groove is not just about longevity; it's a critical safety feature. The groove's surface finish also matters; a smooth, hardened surface minimizes friction, allowing the chain to articulate freely without sticking or jerking, which can initiate pendulum motions in the load.

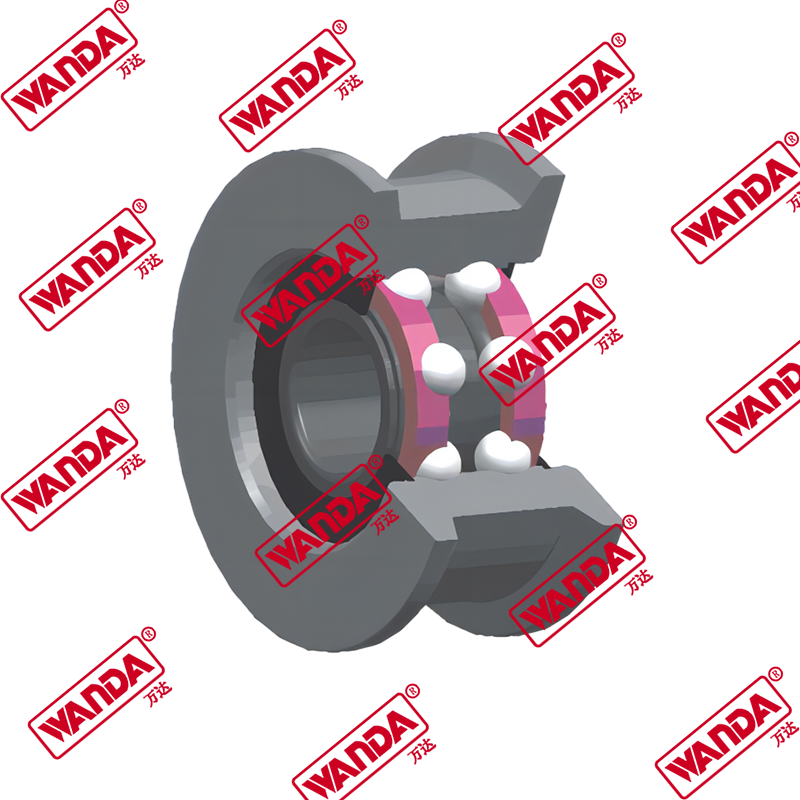

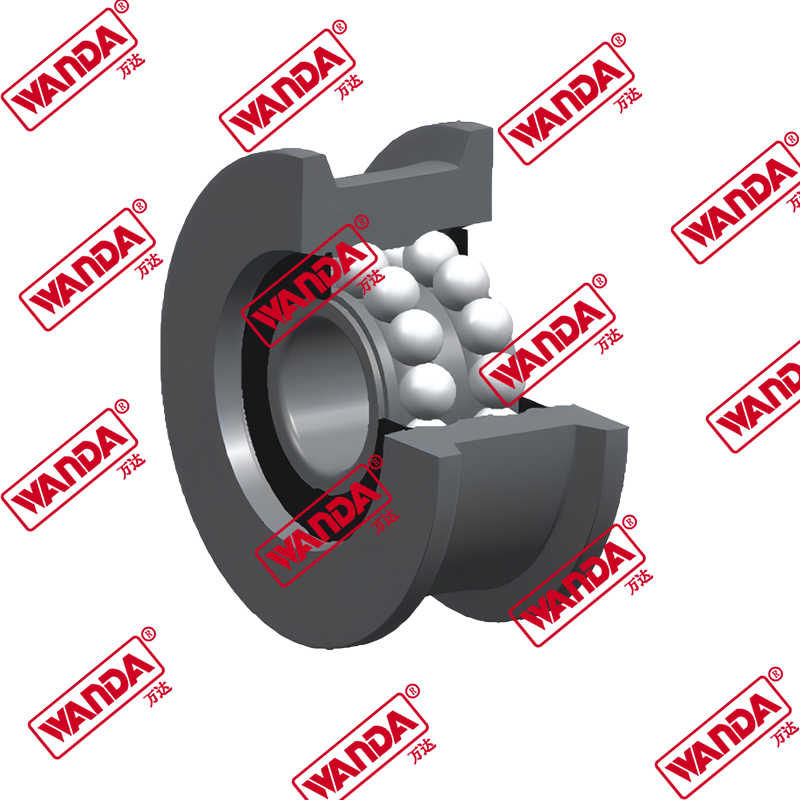

Bearing Integrity and Smooth Operation

The quality and condition of the pulley bearings are directly proportional to the smoothness of lift initiation and descent. Worn or poorly sealed bearings introduce resistance and "stick-slip" motion—a phenomenon where the chain movement is hesitant and jerky. This jerkiness is directly transmitted to the load carriage and forks, causing the load to shake at the start or stop of movement. Sealed, lubricated-for-life bearings or high-grade roller bearings ensure buttery-smooth rotation, enabling precise, gradual acceleration and deceleration of the chain, which is fundamental for keeping loads, particularly those with a high center of gravity, perfectly stable.

System Rigidity and Mast Alignment

A pulley must be mounted within a rigid system. The pulley housing and mast structure must prevent flex under load. If the pulley axle or mounting points deflect, the alignment between the chain and the groove is compromised. This misalignment forces the chain to rub against the groove's flange, creating uneven wear, increased friction, and potentially causing the chain to "walk" or derail. Such instability directly threatens load security. Therefore, the design of the pulley hub and its integration into the mast is as important as the pulley itself. Regular inspection for forklift chain pulley alignment issues is a key preventative maintenance step to preserve stability.

Optimizing Lifting Efficiency Through Pulley Engineering

Lifting efficiency encompasses speed, energy consumption, and component longevity. An efficient system lifts faster with less motor strain, uses less energy, and reduces wear on the chain and other drivetrain parts.

Reducing Friction: The Efficiency Multiplier

Friction is the enemy of efficiency. Every bit of friction in the pulley system converts useful motor power into wasted heat and wear. Design choices that minimize friction have a compound positive effect. This starts with the materials and surface treatments mentioned earlier. Furthermore, the pulley's diameter is a key factor. A larger diameter pulley reduces the chain's bending angle as it engages and disengages, which significantly lowers the energy lost to chain articulation (internal link friction). While larger pulleys may have spatial constraints within the mast, their use is a hallmark of efficient forklift pulley and chain systems. The bearing selection, again, plays a starring role. Low-friction bearings reduce the torque required to initiate pulley rotation, allowing the hydraulic motor to work easier and consume less fuel or electricity per lift cycle.

Weight and Rotational Inertia Considerations

The pulley's mass affects how quickly the lifting system can respond. A lighter pulley (like a composite one) has lower rotational inertia, meaning it can accelerate and decelerate more quickly with less energy. This can contribute to slightly faster cycle times in applications involving many short lifts. However, this must be balanced against strength requirements. The pursuit of lightweight design must not compromise the groove's resistance to deformation or the hub's structural integrity. Engineers often use finite element analysis to design pulleys that are light yet strong, removing material from non-critical areas while reinforcing high-stress zones.

Durability and Total Cost of Ownership

Efficiency is measured over the long term, not just at peak performance when new. A pulley that wears out quickly loses its precise groove geometry, increasing friction and instability, which in turn forces the motor to work harder. This leads to a vicious cycle of increased energy consumption and accelerated wear on the much more expensive lift chain. A durable pulley, perhaps with a hardened groove surface or superior bearing seals, maintains its optimal performance characteristics for thousands of hours. This directly contributes to sustained lifting efficiency and lower total cost of ownership. When selecting a forklift mast pulley specification guide, one must consider not just the initial price, but the specification of materials and tolerances that guarantee enduring performance.

Selecting the Right Pulley: A Guide for Optimal Performance

Choosing the correct chain pulley is a systematic decision that should be based on operational data and future requirements, not just a like-for-like replacement.

Cross-Referencing Specifications and Tolerances

Never assume compatibility. Use the equipment's model number and a reliable forklift mast pulley specification guide to identify the exact part. Pay close attention to:

- Sheave Diameter and Groove Profile: Must match the chain size and type exactly.

- Bore Size and Keyway Specifications: Must fit the mast's axle perfectly to avoid misalignment.

- Load Rating: The pulley's rated capacity should meet or exceed the forklift's maximum lift capacity.

- Bearing Type and Seal Rating: Sealed bearings (e.g., with an IP rating) are essential for dirty or wet environments.

Installing an underspecified or incompatible pulley, even if it fits physically, is a direct compromise on stability, efficiency, and safety.

The Importance of Professional Installation and Maintenance

Even the best-designed pulley will fail if installed incorrectly. Proper installation ensures perfect alignment, correct bearing pre-load (if applicable), and secure fastening. Post-installation, a regimen of periodic inspection for wear, smooth rotation, and forklift chain pulley alignment issues is crucial. Listening for unusual noises during operation and checking for shiny wear marks on the chain or groove flanges can provide early warnings. Proactive replacement of a pulley showing signs of a wear-resistant forklift pulley groove breaking down is far more economical than reacting to a chain derailment or motor failure. Ultimately, viewing the pulley as part of an integrated efficient forklift pulley and chain system prompts holistic maintenance, ensuring that every heavy duty forklift pulley replacement contributes to the system's overall health and performance for years to come.