For nearly 50 years, since our establishment in 1969, our commitment has been to the engineering and production of specialized bearing solutions. As a pioneer in China's special bearing industry and an inaugural "little giant" enterprise, we understand that the heart of durable machinery lies in its most critical components. Among these, the forklift combined roller bearing stands out as a fundamental element in material handling equipment, ensuring smooth operation, load stability, and overall safety. This comprehensive guide delves deep into the world of these indispensable bearings, offering detailed insights for maintenance professionals, procurement managers, and engineers.

Understanding the Forklift Combined Roller Bearing

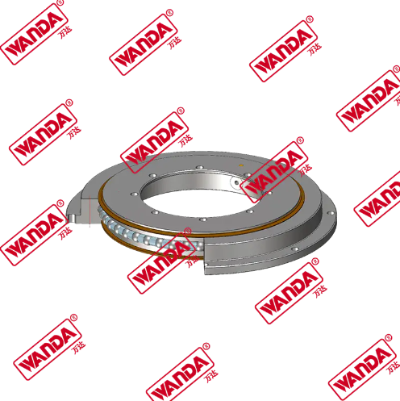

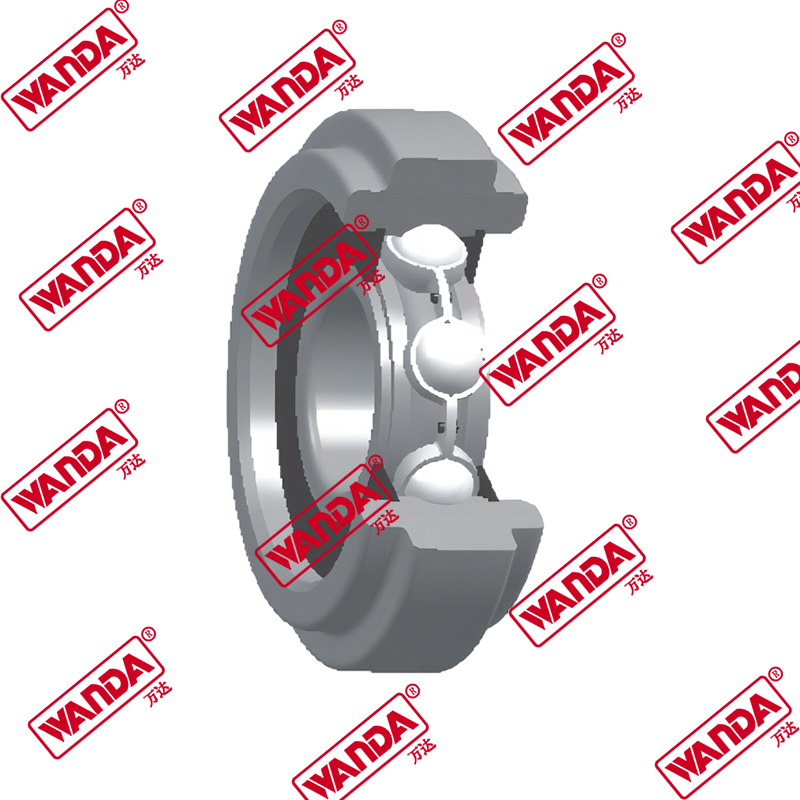

A forklift combined roller bearing is an integrated unit designed to handle both radial and axial (thrust) loads simultaneously. Unlike simple radial bearings, this combined functionality is crucial for the complex motion of forklift masts, which must lift loads vertically while also withstanding lateral forces during tilting and maneuvering.

Core Components and Design

Primary Structural Elements

- Outer Ring: Typically features a spherical or cylindrical raceway to house the rolling elements and facilitate alignment.

- Inner Ring: Often designed with two raceways to accommodate both radial rollers and thrust washers or balls.

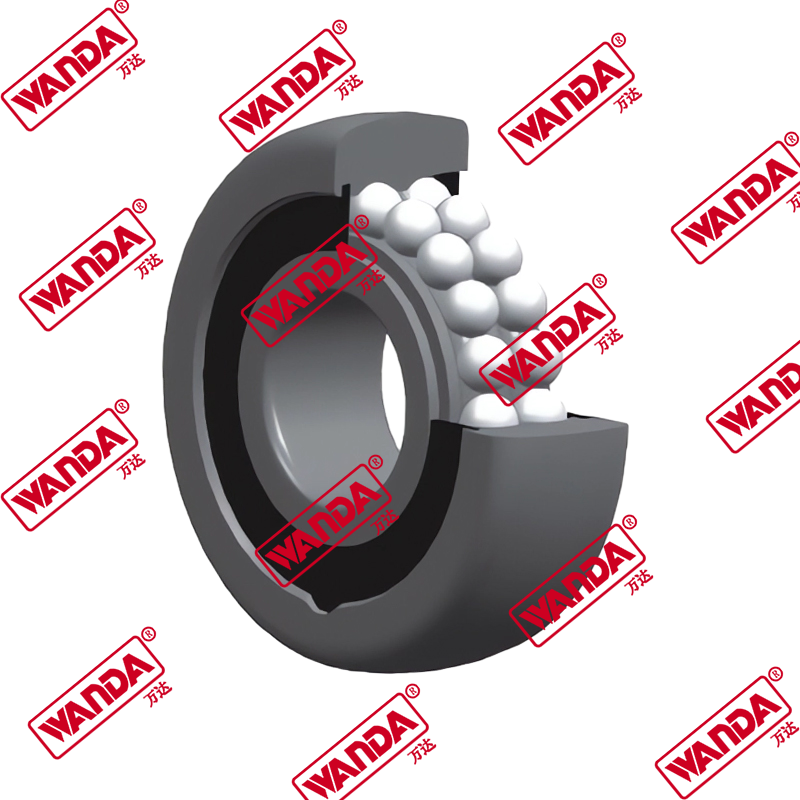

- Rolling Elements: A combination of cylindrical rollers for radial loads and thrust balls or needle rollers for axial loads.

- Cage or Separator: Maintains proper spacing between rolling elements to reduce friction and wear.

- Seals and Shields: Critical for protecting the internal components from contaminants like dust, moisture, and debris common in warehouse and industrial environments.

How It Works in a Forklift Mast

The bearing is typically installed at the connection points between the mast channels. As the hydraulic cylinders lift the inner channels, the combined bearings facilitate smooth vertical travel (radial load) while also managing the thrust forces generated when the mast tilts forward or backward (axial load). This dual-load capacity prevents binding and ensures precise, controlled movement of the load.

Selecting the Right Bearing: A Detailed Comparison

Choosing the correct forklift combined roller bearing is not a one-size-fits-all process. The optimal bearing varies significantly based on the forklift's application and duty cycle. For instance, a bearing suitable for light-duty electric forklifts in a clean environment is vastly different from one needed for a high-capacity diesel forklift in a lumber yard. The following table breaks down the key selection criteria to guide your choice.

| Selection Criteria | Standard-Duty Application | Heavy-Duty Application |

| Load Capacity | Designed for lower to medium load charts and regular indoor use. | Engineered for high-capacity lifting, frequent overloads, and intense shock loads. |

| Sealing Technology | Basic contact seals or shields adequate for controlled environments. | Advanced multi-lip seals or labyrinth seals are essential for wet, dusty, or abrasive conditions. |

| Material & Heat Treatment | Standard bearing steel with conventional hardening. | Alloy steel subjected to specialized carburizing or through-hardening processes for superior core toughness and surface hardness [1]. |

| Lubrication | Pre-greased with standard lithium-based grease. | Often requires high-performance, extreme-pressure (EP) grease, sometimes with re-lubrication features. |

| Ideal Use Case | Warehousing, retail distribution centers, light manufacturing. | Ports, steel mills, construction sites, lumber yards, mining operations. |

For a heavy duty combined roller bearing for forklift, the emphasis on enhanced sealing and material science is non-negotiable to prevent premature failure.

Step-by-Step Maintenance and Troubleshooting

Proactive maintenance is the most effective strategy to extend bearing life and avoid costly downtime.

Routine Inspection and Lubrication

Visual and Auditory Checks

- Look for visible cracks, rust, or pitting on bearing surfaces.

- Listen for grinding, popping, or scraping noises during mast operation.

- Check for excessive play or wobble in the mast channels.

Proper Lubrication Practices

Understanding how to lubricate a combined roller bearing on forklift correctly is vital. Incorrect lubrication is a leading cause of failure.

- Always use the grease type specified by the forklift or bearing manufacturer.

- Clean grease fittings thoroughly before applying new grease to avoid injecting contaminants.

- Apply grease until clean grease is seen purging from the seal, indicating old, contaminated grease has been displaced.

Identifying and Diagnosing Common Failures

Recognizing the early signs of wear in forklift mast bearings can prevent catastrophic mast failure.

- Uneven or Jerky Mast Movement: Often indicates brinelling (indentations on raceways) or contaminated grease.

- Excessive Mast "Chatter" or Lean: Suggests significant wear on the radial rollers, reducing load support.

- Inability to Hold Tilt Position: Points to wear in the thrust component of the bearing, allowing axial drift.

Executing a Safe Replacement

When repairs are necessary, following a structured forklift combined roller bearing replacement procedure ensures safety and longevity.

- Safety First: Lower the mast completely, secure the forklift, and disconnect the battery.

- Mast Disassembly: Carefully disassemble the mast sections according to the service manual. Use proper lifting equipment for mast channels.

- Bearing Removal: Use appropriate pullers to remove the old bearing. Avoid damaging the mast housing.

- Preparation and Installation: Clean the housing thoroughly. Press the new bearing squarely into place using a suitable tool, applying force to the correct ring (usually the one with the tight fit).

- Reassembly and Testing: Reassemble the mast, apply fresh grease, and perform a series of low-load function tests before returning to service.

Cost Considerations and Lifecycle Management

When evaluating the cost of replacing forklift mast bearings, it's imperative to consider Total Cost of Ownership (TCO). The cheapest bearing upfront can become the most expensive due to frequent failures, unplanned downtime, and potential collateral damage to the mast structure.

Factors Influencing Replacement Cost

- Bearing Quality and Specification: Precision-grade, heavy-duty bearings command a higher price but offer exponentially longer service life.

- Labor Intensity: Mast disassembly is labor-heavy. Replacing all bearings during one service event is often more economical.

- Downtime Impact: The cost of lost productivity often far exceeds the parts and labor costs.

Maximizing Bearing Lifespan

- Adhere strictly to the manufacturer's lubrication schedule and type.

- Implement regular operator training to avoid abusive practices like harsh tilting under load.

- Keep the mast clean from build-up of debris that can compromise seals.

Technological Advancements and Future Trends

Bearing technology is continuously evolving. Current research focuses on advanced materials like ceramic hybrids for reduced weight and friction, as well as integrated sensor technology. "Smart" bearings with embedded sensors can monitor temperature, vibration, and load in real-time, enabling predictive maintenance and preventing unexpected failures [2]. These innovations align with the industry's move towards IoT-connected material handling equipment.

Frequently Asked Questions (FAQ)

1. How often should I lubricate my forklift's combined roller bearings?

The interval depends entirely on the operating environment and frequency. A good baseline is to follow the forklift manufacturer's service manual, which typically recommends greasing every 150-250 operating hours. In extremely dusty or wet conditions, this interval should be shortened significantly.

2. Can I replace just one bearing, or should I do them all?

It is highly recommended to replace bearings in sets (at least per mast stage). If one bearing has failed due to wear, the others in the same assembly are likely nearing the end of their service life. Replacing all simultaneously ensures even load distribution and prevents immediate future downtime.

3. What is the most common cause of premature bearing failure?

Contamination is the leading cause. When seals fail or are inadequate, abrasive particles enter the bearing raceway, causing rapid wear and spalling. The second most common cause is improper lubrication, either using the wrong grease type, under-lubrication, or over-lubrication which can cause seal damage.

4. Are there visual signs that can warn me before a bearing completely fails?

Yes. Before catastrophic failure, you may observe increased mast play, visible grease leakage (indicating seal failure), fine metal particles in the purged grease, or a noticeable increase in operating noise during lifting and tilting cycles. These are clear signs of wear in forklift mast bearings.

5. Is the high cost of a premium heavy-duty bearing justified?

Absolutely. For demanding applications, a heavy duty combined roller bearing for forklift is an investment. It is engineered with superior materials, heat treatment, and sealing to withstand shock loads and harsh environments. The justification comes from drastically extended service intervals, reduced risk of unplanned mast failure, and protection of the more expensive mast structure itself.

The forklift combined roller bearing is a masterpiece of specialized engineering that plays an outsized role in the performance, safety, and profitability of material handling operations. From understanding the nuanced forklift combined roller bearing replacement procedure to mastering how to lubricate a combined roller bearing on forklift, informed maintenance is key. By learning to spot the early signs of wear in forklift mast bearings and investing in the correct specification—such as a heavy duty combined roller bearing for forklift when needed—operators can make smart decisions that positively impact the cost of replacing forklift mast bearings over the long term. With nearly five decades of specialization behind us, we continue to support industry excellence through innovation and precision in every component we engineer.

References

[1] Harris, T. A., & Kotzalas, M. N. (2006). *Essential Concepts of Bearing Technology* (5th ed.). CRC Press. (Reference on bearing material science and heat treatment processes).

[2] Tandon, N., & Choudhury, A. (2019). A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. *Tribology International, 129*, 405-428. (Reference on bearing condition monitoring and sensor technology).