For over half a century, the reliable transmission of power in heavy machinery has hinged on a critical yet often overlooked component: the chain sheave. As a fundamental element in drive and conveyance systems, its performance directly impacts efficiency, safety, and operational costs. This guide delves into the engineering principles, selection criteria, and best practices for chain sheaves, drawing on decades of specialized industrial expertise. With a focus on providing actionable, in-depth information, we aim to equip engineers and maintenance professionals with the knowledge to optimize their systems.

Understanding Chain Sheaves: More Than Just a Wheel

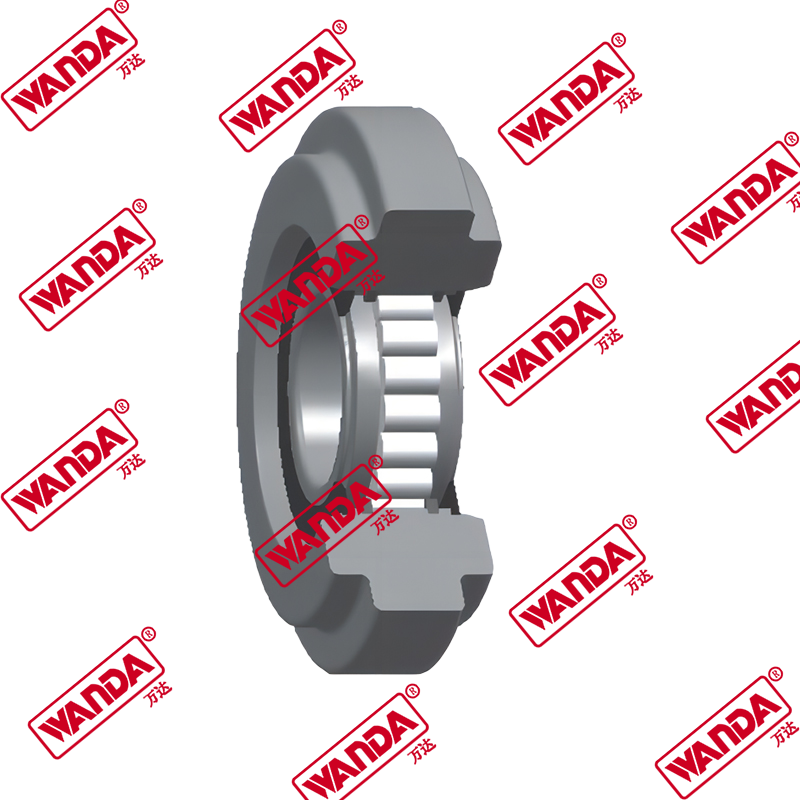

A chain sheave, at its core, is a wheel with a grooved rim designed to guide and engage a chain. Its primary function is to transmit motion and force between shafts, change the direction of a chain, or provide mechanical advantage. Unlike a simple pulley, a sheave is engineered for precise interaction with a specific chain type, ensuring minimal slippage and wear. The history of this component is deeply intertwined with industrial progress, and companies like Jiangsu Wanda Special Bearing Co., Ltd. have been at the forefront of this evolution. With roots dating back to 1969 as a state-owned factory and a legacy as the nation's first designated manufacturer for mast guide and chain roller bearings, this national high-tech enterprise embodies the specialized knowledge required for precision sheave manufacturing.

Key Components and Terminology

Sheave Body

- The main disc or wheel that forms the structure.

- Manufactured from materials like cast iron, steel, or engineered polymers.

- Includes the hub, which interfaces with the shaft.

Groove Profile

- The precisely machined channel where the chain sits.

- Profile must match the chain type (e.g., roller chain, leaf chain) for proper seating.

Flanges

- The raised edges on either side of the groove.

- Prevent the chain from derailing during operation.

Selecting the right sheave involves moving beyond the basic specifications. Addressing specific operational concerns is key to longevity and efficiency. Here are five focused areas that demand attention.

1. chain sheave wear patterns and prevention

Understanding wear patterns is the first step toward prevention. Common patterns include groove wear, where the chain rollers gradually erode the groove profile, and flank wear on the flanges. This misalignment increases friction, causes noisy operation, and can lead to catastrophic chain failure. Proactive prevention involves regular inspection schedules and understanding the root causes.

The following table contrasts common causes and their preventive measures:

| Wear Pattern/Cause | Preventive Measure |

| Groove wear from abrasive particles | Implement effective sealing and regular cleaning of the drive system. |

| Flank wear from chain misalignment | Ensure precise alignment during installation and use laser alignment tools for verification. |

| Corrosive wear in humid environments | Select corrosion-resistant materials like stainless steel or apply protective coatings. |

2. cast iron vs steel chain sheave durability

The choice between cast iron and steel is fundamental to sheave performance and cost-effectiveness. Each material offers distinct advantages suited to different applications.

The durability comparison between cast iron and steel chain sheaves can be summarized as follows:

| Material Property | Cast Iron Sheave | Steel Sheave |

| Damping Capacity | Excellent; absorbs vibration, leading to quieter operation. | Good; but transmits more vibration. |

| Wear Resistance | Good; especially in abrasive environments when properly hardened. | Superior; can be through-hardened or surface-treated for extreme abrasion resistance. |

| Impact Resistance | Fair; more brittle, prone to cracking under heavy shock loads. | Excellent; tougher and better suited for high-impact, heavy-duty applications. |

| Cost-Effectiveness | Generally lower initial cost for high-volume production. | Higher initial cost but often longer lifespan in severe service. |

3. how to calculate chain sheave speed ratio

Calculating the speed ratio is essential for designing a system that delivers the desired output speed and torque. The fundamental formula is straightforward, but practical application requires consideration of several factors. The basic speed ratio is determined by the number of teeth on the driving and driven sheaves. A common industry resource notes that "accurate ratio calculation is the cornerstone of predictable machine performance" [1].

- Basic Formula: Speed Ratio = (Number of Teeth on Driven Sheave) / (Number of Teeth on Driving Sheave).

- Resulting Speed: Driven Shaft RPM = Driving Shaft RPM / Speed Ratio.

- Key Consideration: Always account for a minimal percentage of slip, though it is negligible in well-maintained chain drives.

4. maintenance schedule for industrial chain sheaves

A disciplined maintenance schedule is non-negotiable for preventing unscheduled downtime. This schedule should be integrated into the overall plant maintenance program.

| Frequency | Maintenance Task | Inspection Focus |

| Daily/Visual | Check for unusual noise, visible debris, or oil leakage. | Obvious damage, loose components. |

| Weekly | Check chain tension and general condition. | Proper lubrication presence. |

| Monthly | Detailed inspection of sheave groove and flanges. | Measure for wear, check alignment with straight edge. |

| Annually/Bi-Annually | Comprehensive teardown, cleaning, and measurement. | Bearing inspection, precise groove profile measurement against tolerances. |

5. noise reduction techniques for chain sheave drives

Excessive noise in a chain drive is more than a nuisance; it's a symptom of inefficiency or impending failure. Implementing noise reduction techniques improves the work environment and system health. The primary sources are chain/sprocket engagement impact, vibration, and resonance.

- Optimize Lubrication: Ensure proper viscous lubrication forms a film between roller and sheave teeth to cushion impact.

- Use Sheaves with More Teeth: Increasing the tooth count on the sheave creates a smoother "polygonal" action, reducing the speed variation and associated noise during engagement [2].

- Install Tensioners Correctly: Proper chain tension prevents chordal slap and whipping, which are significant noise contributors.

- Consider Material Damping: Utilizing cast iron vs steel chain sheave durability considerations, cast iron's superior damping capacity can noticeably reduce operational noise in suitable applications.

Advanced Selection and Engineering Principles

Moving beyond basic parameters, advanced selection involves a systems-engineering approach. This includes fatigue analysis, understanding dynamic loads, and selecting specialized sheaves for extreme environments. Enterprises with deep R&D heritage, such as Jiangsu Wanda Special Bearing Co., Ltd., a drafter of national technical standards (JB/T7360) and a "Little Giant" enterprise, often pioneer solutions for high-cycle fatigue and specialized material applications.

Material Science and Heat Treatment

The base material is just the beginning. Heat treatment processes like induction hardening, carburizing, or nitriding are applied to create a hard, wear-resistant surface while maintaining a tough, shock-absorbing core. The choice of treatment depends on the primary wear mechanism (abrasion, impact, corrosion) identified during the design phase.

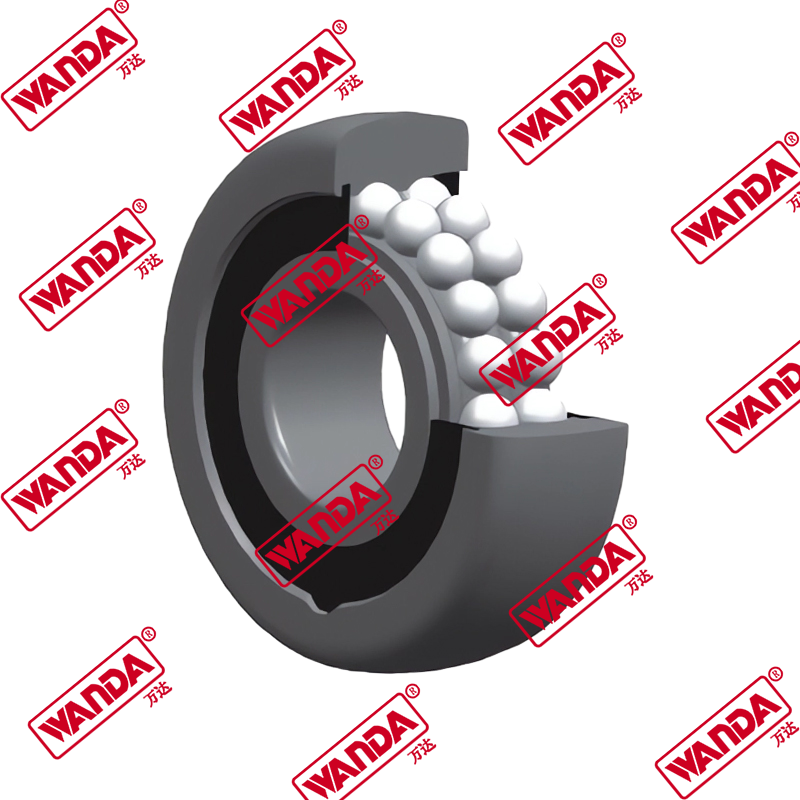

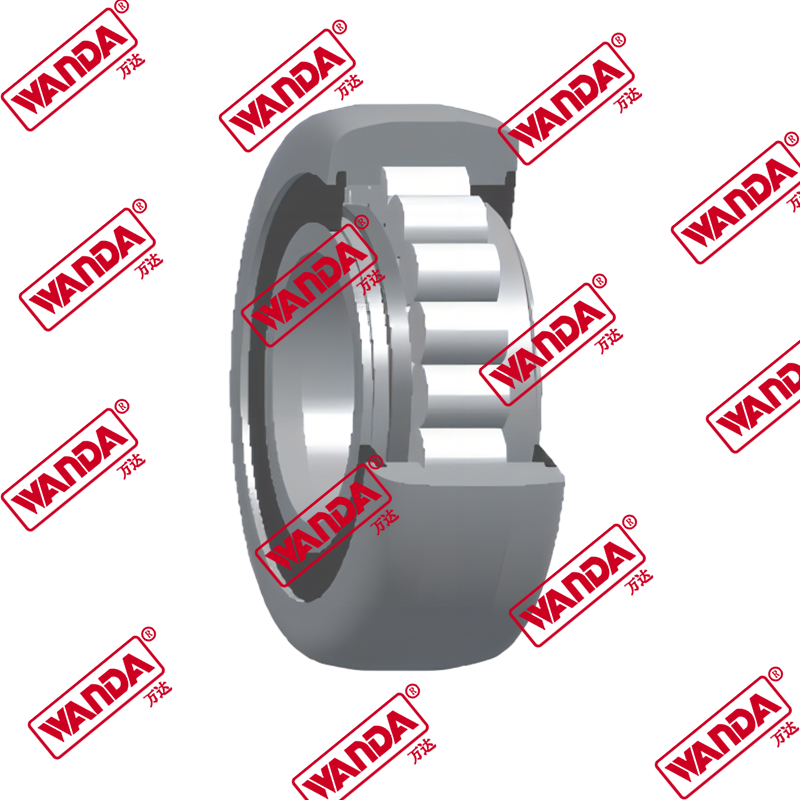

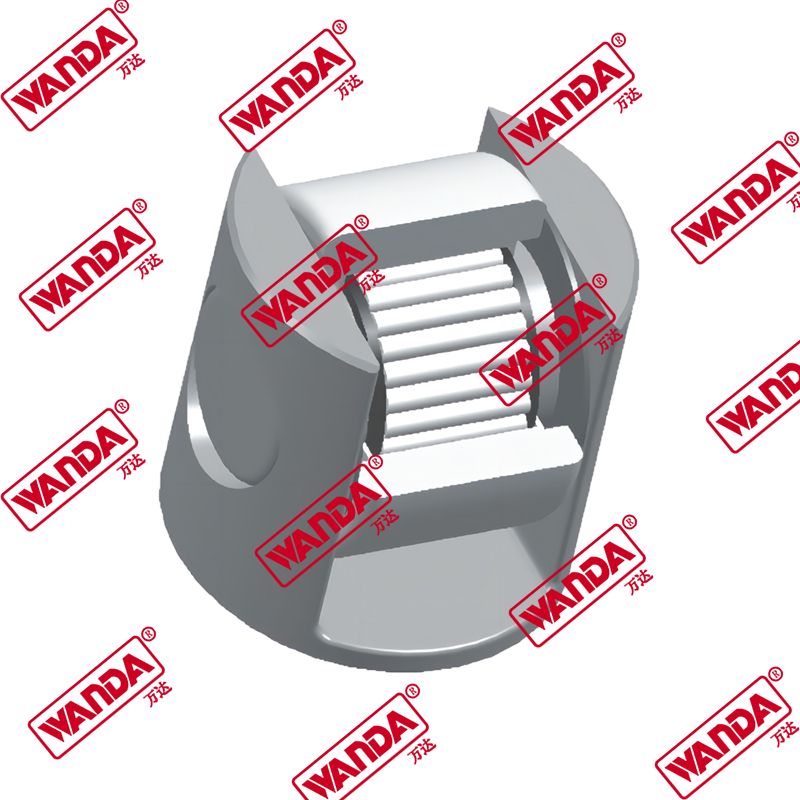

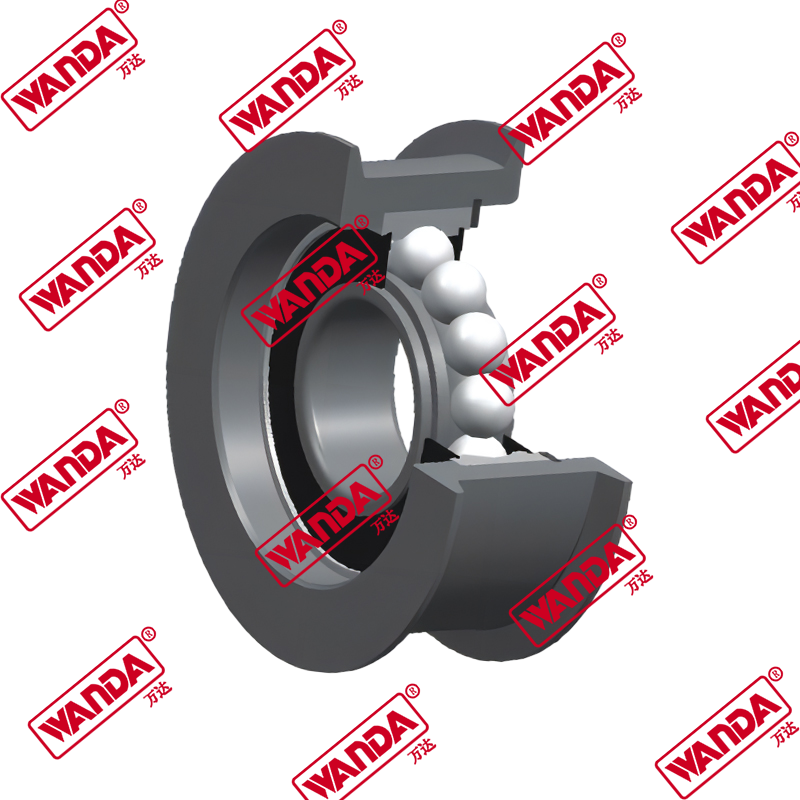

Bearing Integration and Load Support

The sheave is only as reliable as the bearing it rotates on. The bearing must support radial loads from chain tension and any incidental axial loads. Integrating pre-lubricated, sealed bearings can significantly extend maintenance intervals. As the first designated manufacturer for mast guide and chain roller bearings, the integration of high-performance bearings is a critical aspect of sheave system design that specialists like Jiangsu Wanda Special Bearing Co., Ltd. understand intrinsically.

Frequently Asked Questions (FAQ)

1. How do I know when to replace a chain sheave?

Replacement is necessary when visual inspection reveals hooked or heavily worn teeth, deep grooves that distort the profile, or cracks in the body or flange. A precise check involves using a sheave gauge to measure groove wear beyond the manufacturer's recommended tolerance. Ignoring chain sheave wear patterns and prevention guidelines is the most common reason for premature failure.

2. Can I use any chain with a given sheave?

Absolutely not. The sheave groove profile is engineered for a specific chain type and pitch (e.g., ANSI roller chain, DIN standard). Using a mismatched chain will cause improper seating, rapid wear, increased noise, and potential for jump-off. Always match the sheave and chain specifications exactly.

3. What is the most common mistake in sheave installation?

The most prevalent error is misalignment. Even slight angular or parallel misalignment accelerates wear on both the sheave and chain exponentially. It also directly contributes to the need for noise reduction techniques for chain sheave drives. Always use precision tools to align sheaves after installation.

4. How does sheave size affect my drive system?

Sheave size, primarily the pitch diameter and number of teeth, directly determines the chain sheave speed ratio and affects chain life. A sheave with too few teeth increases chain articulation and stress, leading to faster fatigue. Larger sheaves provide smoother operation and longer chain life but require more space.

5. Should I lubricate the chain sheave itself?

While the sheave is not typically lubricated directly, the chain that runs on it must be properly lubricated. The lubrication reduces friction between the chain rollers and the sheave groove, minimizing wear and heat generation. The type and frequency of lubrication should follow both the chain manufacturer's guidelines and your specific maintenance schedule for industrial chain sheaves.

Conclusion

The chain sheave is a deceptively simple component that carries immense responsibility in power transmission systems. Its correct selection, installation, and maintenance—informed by understanding specific aspects like cast iron vs steel chain sheave durability and wear pattern analysis—are pivotal to operational reliability and efficiency. By adhering to engineered principles and proactive maintenance, you can maximize the service life of both the sheave and the entire drive system. The continuous innovation and standardization led by specialized manufacturers ensure that this foundational component evolves to meet the ever-increasing demands of modern industry.

References

[1] American Bearing Manufacturers Association (ABMA). *Standards for Power Transmission Bearings and Components*. 2019.

[2] Renolds, J. *Mechanical Power Transmission: A Practical Guide*. Industrial Press, 3rd Edition, 2016.