Forklift Bearing performance directly affects the safety, efficiency, and service life of industrial vehicles. In modern logistics, manufacturing, and warehousing environments, forklifts operate under high loads, frequent start-stop cycles, and complex motion patterns. Selecting the right bearing solution is critical for maintaining operational stability and minimizing downtime.

Understanding Forklift Bearing Requirements

Load Characteristics in Forklift Operations

Dynamic and Static Load Conditions

- Forklifts experience alternating loads during lifting, lowering, and transportation.

- Mast movement generates combined radial and axial forces.

- Long-term static loads occur when forklifts remain stationary with elevated cargo.

Load Comparison

Different forklift components experience varying load types and intensities.

| Component | Main Load Type | Load Intensity |

| Mast System | Radial + Axial | Very High |

| Wheels | Radial | High |

| Steering System | Axial | Medium |

Operating Environment Challenges

- Dust, vibration, and impact forces accelerate wear.

- Temperature variations affect lubrication stability.

- Corrosive environments require enhanced material protection.

Types of Forklift Bearings and Functional Differences

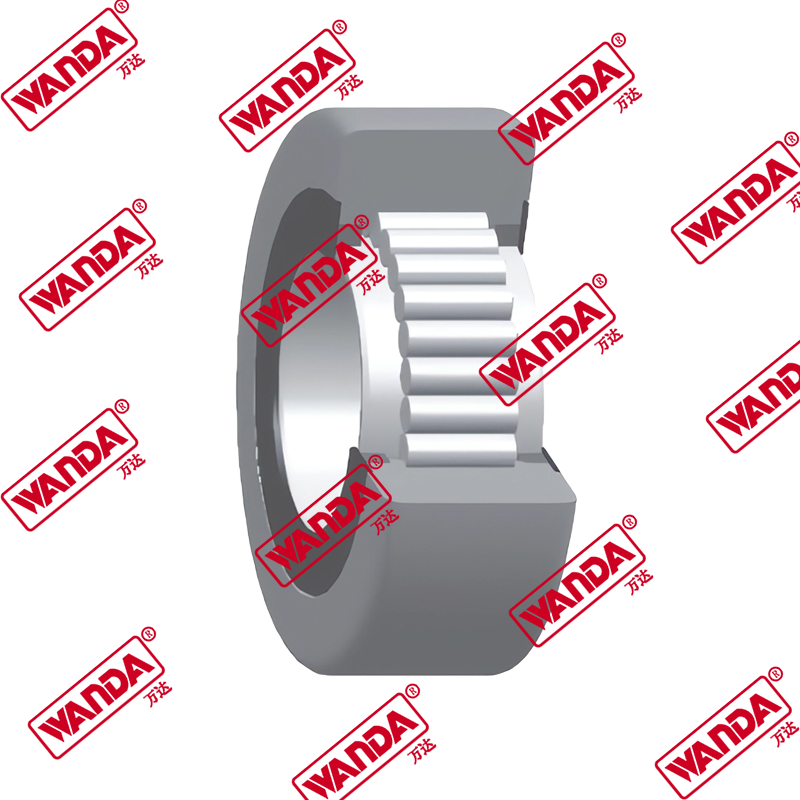

Mast Bearings

- Mast bearings guide vertical lifting motion.

- They must support heavy loads with minimal deformation.

- forklift mast bearing solution designs focus on high stiffness and wear resistance.

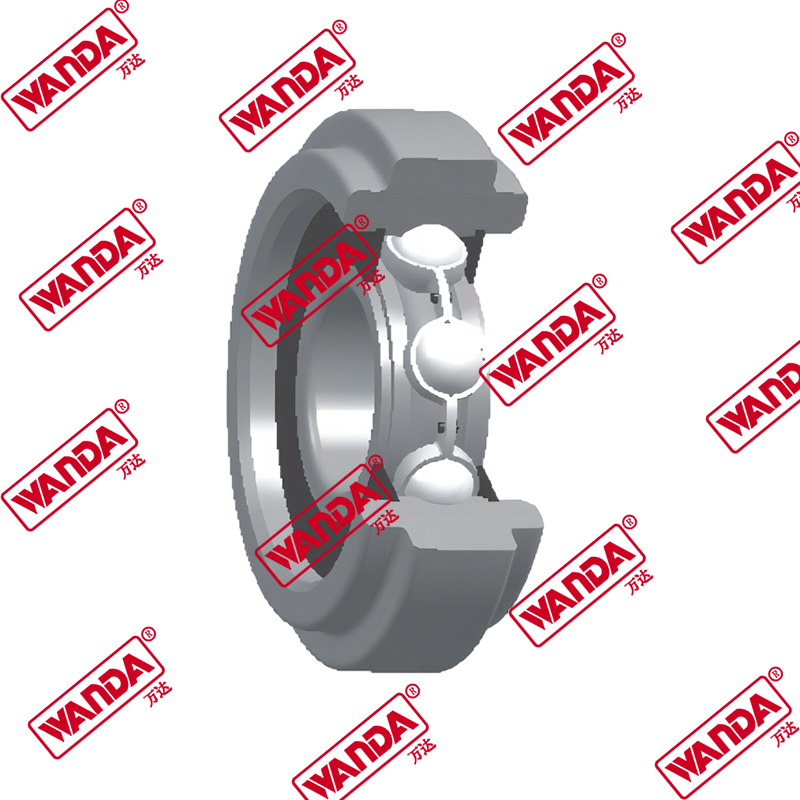

Wheel and Axle Bearings

- Wheel bearings support continuous rolling under heavy loads.

- They must resist shock and uneven ground conditions.

- heavy duty forklift bearing structures improve durability in harsh operations.

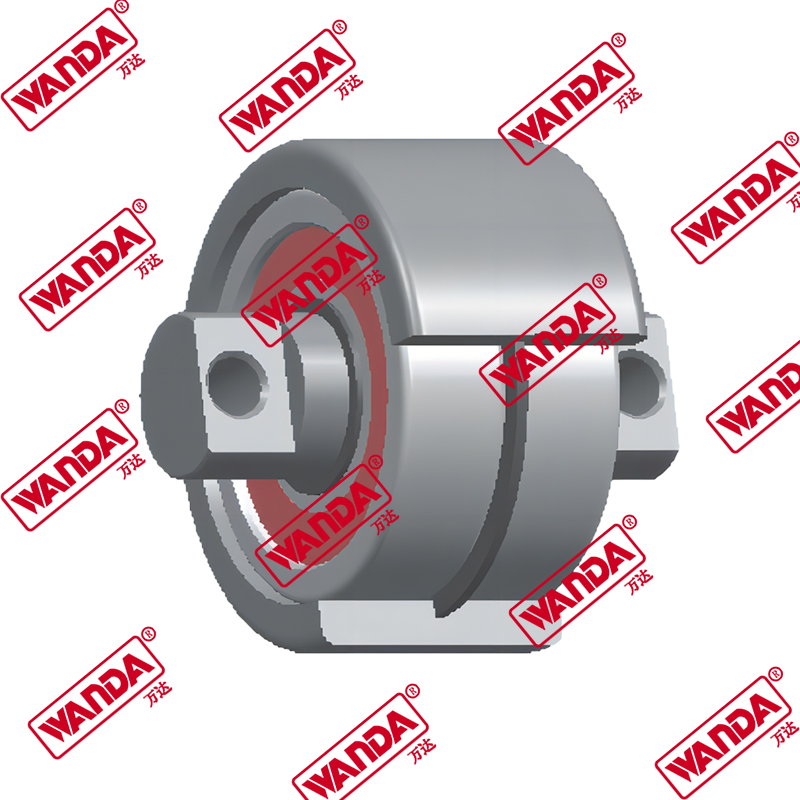

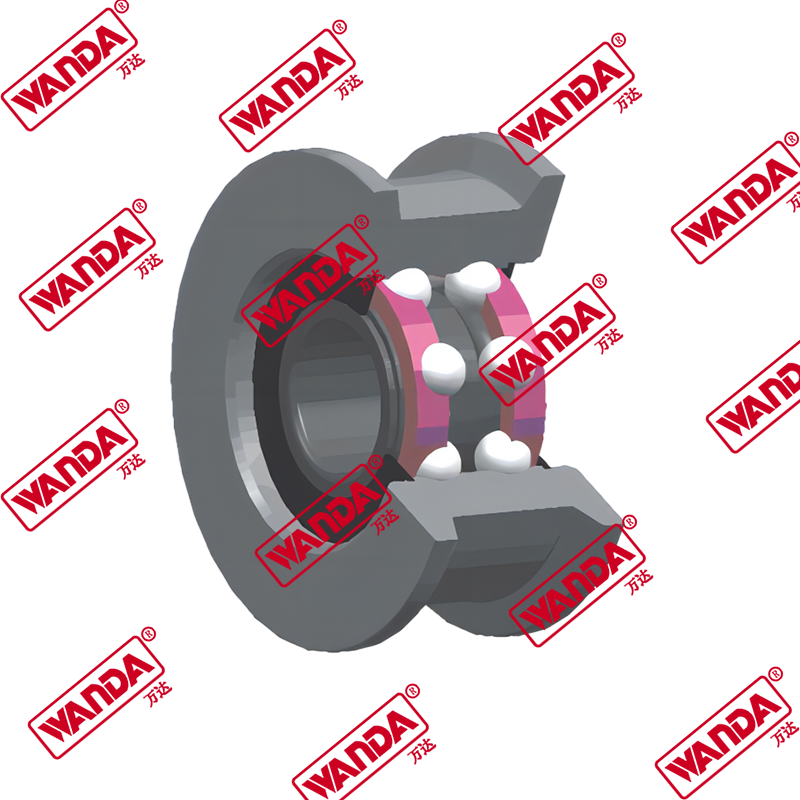

Thrust and Slewing Bearings

- These bearings manage axial forces during steering and lifting.

- They enhance stability and smooth rotational motion.

Key Performance Factors for Forklift Bearings

Load Capacity Comparison

Higher load capacity improves safety margins and reduces fatigue damage.

| Bearing Design | Load Capacity | Application Suitability |

| Standard Design | Moderate | Light-duty forklifts |

| Reinforced Design | High | Heavy industrial use |

Wear Resistance and Service Life

- Optimized heat treatment enhances surface hardness.

- Advanced lubrication grooves reduce friction.

- forklift bearing for high load applications focuses on long-term reliability.

Precision and Stability

- High precision minimizes vibration.

- Stable operation protects surrounding components.

Engineering and Manufacturing Approach at Jiangsu Wanda special bearing Co.,Ltd

Research and Experimental Capabilities

- Provincial technology center supports bearing innovation.

- Advanced experimental equipment validates performance.

- Engineering teams focus on industrial vehicle bearing design.

Production Process Control

- Mass production lines ensure consistency.

- Precision machining maintains dimensional accuracy.

- Strict inspection systems safeguard quality.

Bearing Function Design for Industrial Vehicles

- Load distribution optimization reduces stress concentration.

- Custom geometries match specific forklift structures.

- custom forklift bearing manufacturer capability enables tailored solutions.

Forklift Bearing Selection Guide

Matching Bearings to Load and Motion

- Identify maximum lifting capacity.

- Analyze motion frequency and direction.

- Consider environmental exposure.

Standard vs Custom Bearing Solutions

| Solution Type | Flexibility | Performance Optimization |

| Standard Bearing | Limited | General-purpose |

| Custom Bearing | High | Application-specific |

Future Trends in Forklift Bearing Technology

High-Load and Long-Life Designs

- Improved material fatigue resistance.

- Optimized internal geometry.

Standardization and Performance Optimization

- Development of industry standards.

- Enhanced compatibility across forklift models.

Frequently Asked Questions

1. What is the most critical factor when selecting a forklift bearing?

Load capacity and operating conditions are the primary factors.

2. How do mast bearings differ from wheel bearings?

Mast bearings handle combined loads, while wheel bearings mainly support radial forces.

3. Why are custom forklift bearings important?

Custom designs ensure optimal performance for specific load and motion requirements.

4. How does bearing precision affect forklift stability?

Higher precision reduces vibration and improves control accuracy.

5. What role does bearing design play in service life?

Optimized design minimizes wear and extends operational lifespan.