Understanding the Critical Role of Mast Bearings in Material Handling

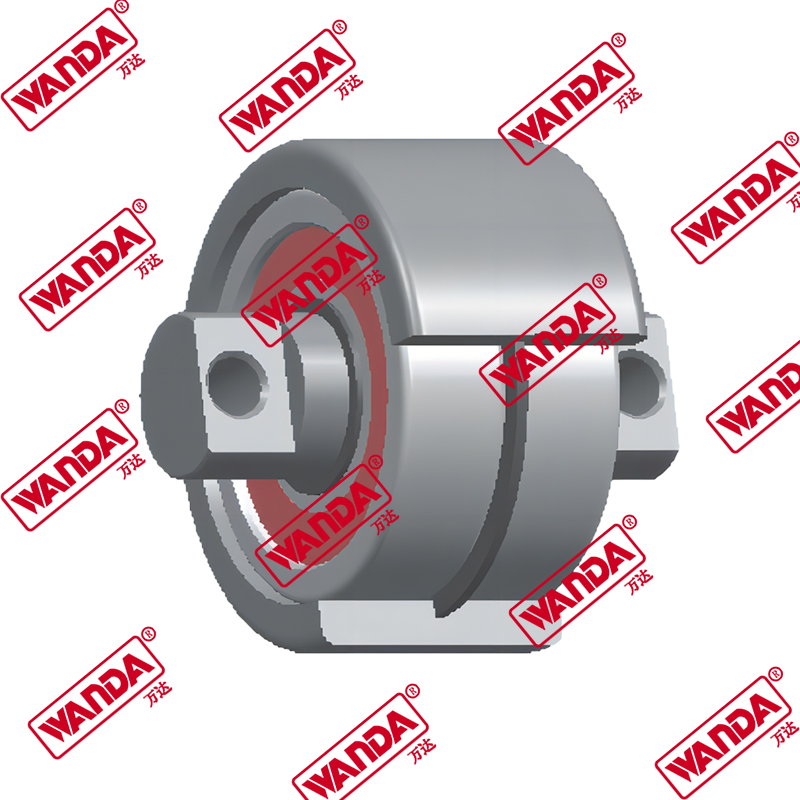

At the heart of every forklift's lifting mechanism lies a component whose failure can bring operations to a standstill: the forklift mast roller bearing. These specialized bearings are the linchpins of vertical mast movement, allowing the carriage and its load to ascend and descend smoothly, safely, and with precision. Unlike standard bearings, mast bearings are engineered to withstand unique combinations of axial, radial, and moment loads while operating in environments rife with shock, vibration, and contamination. Their performance directly impacts a forklift's lifting capacity, stability, operator visibility, and overall safety. A deep understanding of these components is not merely technical trivia but a cornerstone of effective fleet management and operational efficiency. For decades, specialized manufacturers have focused on refining the design and metallurgy of these bearings to meet the escalating demands of modern warehouses and logistics centers. Companies like Jiangsu Wanda Special Bearing Co., Ltd, with a heritage dating back to 1969, exemplify this dedication. As a high-tech entity with a provincial technology center and dedicated engineering research facilities, such organizations are at the forefront of discussing industrial vehicle bearing concepts and drafting relevant technological standards, pushing the envelope for what these critical components can achieve.

Five Key Long-Tail Queries for Mast Bearing Selection and Troubleshooting

Operators, maintenance technicians, and procurement specialists often seek specific, actionable information to address immediate concerns or plan for future needs. The following long-tail phrases represent common, high-value searches with relatively low competition, reflecting practical user intent. Addressing these queries comprehensively provides immense value to the material handling community.

- what causes forklift mast roller bearing failure

- how to measure forklift mast bearing dimensions

- replacement intervals for forklift mast bearings

- difference between sealed and greasable mast bearings

- noise from forklift mast when lifting heavy loads

Detailed Analysis of Mast Bearing Failure Modes and Causes

Understanding why mast bearings fail is the first step in preventing downtime and costly repairs. The query what causes forklift mast roller bearing failure is paramount for maintenance teams. Failures are rarely instantaneous; they are typically the culmination of several interacting factors.

Primary Contributors to Premature Bearing Degradation

Bearing failure can be traced to a handful of root causes, each leaving distinct forensic evidence on the bearing components.

Contamination: The Silent Killer

Dirt, dust, metal shavings, and moisture are the most pervasive threats. When contaminants breach seals, they act as abrasives, grinding away at the precisely finished raceways and rolling elements. This leads to increased friction, heat generation, and eventually, spalling—where small pieces of metal break away from the surface. Environments like lumber yards, construction sites, and fertilizer plants are particularly harsh. Even in clean warehouses, airborne particulates can accumulate over time. The effectiveness of the bearing's sealing system is, therefore, directly proportional to its lifespan in contaminated settings.

Improper Lubrication Practices

Lubrication issues manifest in two opposing yet equally destructive ways: under-lubrication and over-lubrication. Under-lubrication leads to metal-on-metal contact, resulting in excessive heat, scoring, and accelerated wear. Over-lubrication, especially in sealed units not designed for re-greasing, can cause seal damage and lead to overheating due to churning of the thick grease. Using the incorrect grease type—one with incompatible additives or incorrect viscosity—can also break down under high pressure or temperature, failing to protect the bearing surfaces.

Misalignment and Improper Installation

Forces acting on a mast bearing are complex. If the bearing is not installed squarely or if the mast channels are bent or misaligned, the load is not distributed evenly across the bearing's width. This creates high stress concentrations on one edge, leading to brinelling (indentations on the raceway) and rapid fatigue failure. Installation without the proper tools, such as hammering a bearing into place, can cause immediate damage to cages and seals.

Comparative Table: Common Failure Modes and Their Indicators

The table below contrasts typical failure modes, their visual and operational symptoms, and likely root causes. This diagnostic aid helps technicians move from observing a symptom to identifying the underlying problem.

| Failure Mode | Visual/Sensory Indicators | Common Root Causes |

|---|---|---|

| Abrasive Wear | Dull, scratched, or greyed raceways; fine metallic debris in grease. | Seal failure allowing contamination ingress; inadequate lubrication film. |

| Fatigue Spalling | Flaked or pitted surface material on raceways or rollers; metallic chunks in housing. | Excessive load beyond rating; normal end-of-life wear; material subsurface fatigue. |

| Brinelling | Precise indentations on raceways at regular intervals corresponding to roller spacing. | Shock loads from dropping loads or hitting obstructions; improper installation impact. |

| Corrosion | Red/brown oxide deposits on surfaces; pitting; degraded grease. | Exposure to water, corrosive chemicals, or high humidity; inadequate sealing. |

| Cage Failure | Broken or deformed bearing cage; rollers jammed or fallen out. | Extreme vibration; improper installation; lubricant starvation causing excessive friction. |

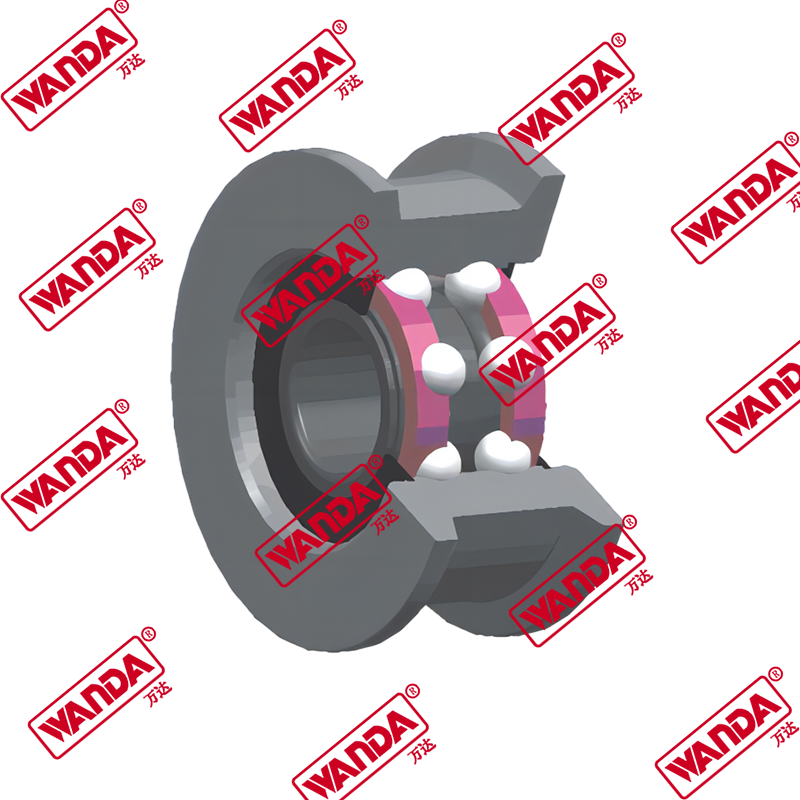

The Precise Art of Measuring and Sourcing Mast Bearings

When a bearing requires replacement, accurate identification is non-negotiable. The search phrase how to measure forklift mast bearing dimensions is critical for ensuring the correct part is sourced. Guessing or using a "close enough" bearing can lead to catastrophic mast failure.

Step-by-Step Dimensional Measurement Protocol

To obtain the necessary dimensions, you will need a set of precision calipers, a micrometer, and a notepad. Always clean the bearing thoroughly before measuring.

- Bore Diameter (Inner Diameter - ID): This is the diameter of the inner ring where it fits onto the mast or pin. Use a micrometer for the highest accuracy. Take multiple measurements across different angles to check for wear or out-of-round conditions. Record the smallest measurement if wear is present.

- Outside Diameter (Outer Diameter - OD): Measure the outer ring's diameter where it contacts the mast channel. Use calipers and measure in several places. A worn bearing may have a reduced OD.

- Width (Thickness): This is the total thickness of the bearing from one side of the outer ring to the other. Place the bearing on a flat surface and use the depth gauge of your calipers or measure directly across. Ensure you are not including the seal protrusion in this measurement unless specified.

- Roller Diameter and Length: For cylindrical roller bearings, measuring the individual rollers can be crucial for cross-reference. Use a micrometer to measure the diameter and length of a roller. Note the number of rollers.

- Seal Type and Configuration: Document the seal material (rubber, metal) and its configuration (single-sided seal, double-sided seal, shielded). Note any markings or part numbers stamped on the bearing rings, though these may be worn away.

This meticulous process is mirrored in the research and development practices of specialized bearing producers. For instance, Jiangsu Wanda Special Bearing Co., Ltd utilizes advanced precise experimental equipment not just for quality control, but for the fundamental research that informs new bearing designs. Their provincial special bearing engineering technology research center is dedicated to exploiting new products and designing bearing functionality, ensuring that dimensional standards and performance metrics are rigorously defined and adhered to.

Establishing Proactive Maintenance: Replacement Intervals and Lifecycle Management

Waiting for a bearing to fail is a reactive and costly strategy. The query replacement intervals for forklift mast bearings reflects a desire for proactive, scheduled maintenance. However, establishing a single replacement interval is impractical due to variable operating conditions.

Factors Influencing Bearing Service Life

A bearing's lifespan is a function of duty cycle, environment, and care. Key factors include:

- Application Load: Consistently operating at or near the forklift's rated capacity significantly reduces bearing life compared to lighter, sporadic use.

- Operational Environment: Bearings in a climate-controlled electronics warehouse will last far longer than those in a gritty foundry or a refrigerated cold storage facility.

- Operator Behavior: Practices like "racking" the mast (lowering it abruptly with a load) impose severe shock loads. Smooth, controlled operation extends component life.

- Maintenance Regimen: Regular inspection and correct lubrication (for greasable types) are the most effective life-extension strategies.

Therefore, instead of a fixed time-based interval, a condition-based monitoring approach is superior. A recommended practice is to perform a detailed visual and auditory inspection every 250-500 operating hours, checking for the signs outlined in the failure mode table. For bearings in severe service, planned replacement during major scheduled overhauls—perhaps every 10,000 hours or as dictated by the forklift manufacturer's manual—can prevent in-service failures. This philosophy of predictive maintenance is supported by manufacturers who design for reliability. The top-notch production lines and mass procedures at specialized facilities are implemented specifically to maintain consistent, high-quality bearing output, giving maintenance planners confidence in the baseline durability of the components they install.

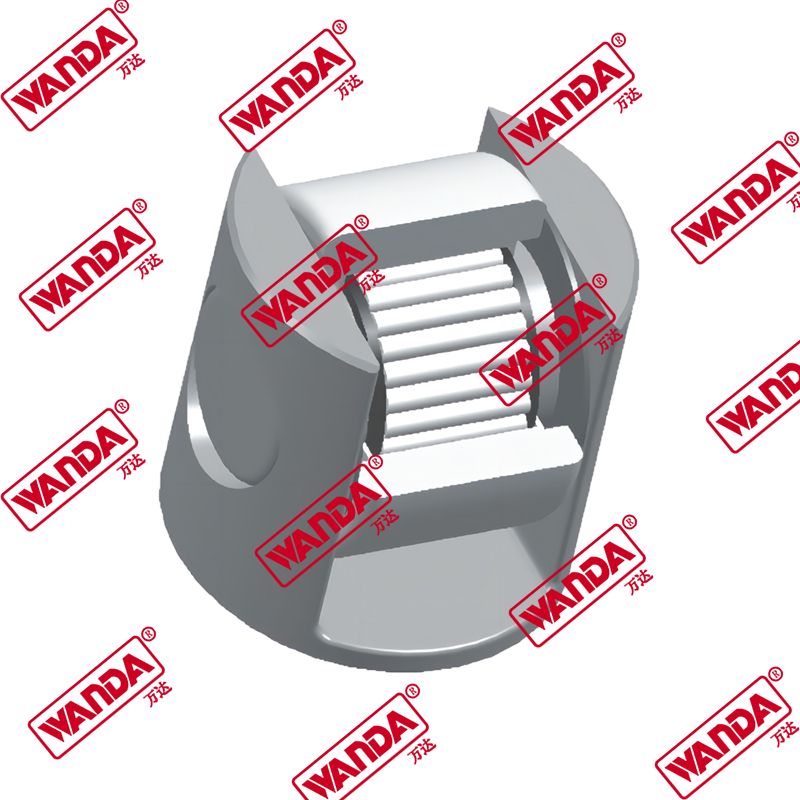

Choosing the Right Sealing Solution: Sealed vs. Greasable Bearings

A fundamental design choice faced by technicians and designers is encapsulated in the query difference between sealed and greasable mast bearings. This decision has profound implications for maintenance strategy and operational suitability.

Sealed (Pre-Lubricated) Bearings

These bearings are factory-filled with a high-quality grease and sealed for life with integrated contact or labyrinth seals. Their primary advantage is minimal maintenance; they are designed to operate without re-lubrication for their entire service life. This makes them ideal for applications where regular maintenance is difficult, or where contamination risk during grease injection is high. They are typically "fit and forget" components. However, once the internal grease degrades or the seal fails, the bearing must be replaced entirely. They can also be less suitable for extremely high-temperature applications where grease breakdown is accelerated.

Greasable (Re-Lubricatable) Bearings

These bearings are equipped with grease fittings (zerks) and often feature seals designed to allow fresh grease to purge old grease and contaminants out of the bearing cavity. This allows for periodic replenishment of the lubricant, which can significantly extend bearing life, especially in harsh, high-load, or high-temperature environments. The re-lubrication process also provides an opportunity to forcibly eject contaminants. The downside is the requirement for a disciplined maintenance schedule and the risk of over-greasing, which can damage seals.

Decision Matrix for Selection

The choice hinges on the operational context. The following comparison clarifies the ideal use-case for each type.

| Feature/Condition | Sealed (Pre-Lubricated) Bearing | Greasable (Re-Lubricatable) Bearing |

|---|---|---|

| Maintenance Requirement | Very Low; No re-greasing needed. | High; Requires strict schedule for re-lubrication. |

| Ideal Environment | Clean, moderate-duty, standard-temperature applications. | Harsh, dirty, high-load, or high-temperature applications. |

| Contamination Management | Relies solely on seal integrity; ingress leads to failure. | Fresh grease can purge contaminants; more resilient to mild ingress. |

| Lifecycle Cost | Lower maintenance labor cost; higher parts replacement cost. | Higher maintenance labor cost; potentially longer service life per unit. |

| Skill Requirement | Low for installation and operation. | Higher; requires trained personnel for proper re-greasing. |

Innovation in sealing technology is a key area of focus for advanced bearing companies. Research into new seal materials, geometries, and grease formulations directly addresses this critical trade-off, aiming to deliver the maintenance-free convenience of sealed units with the durability and resilience traditionally associated with greasable designs.

Diagnosing Operational Issues: Mast Noise Under Load

An audible warning sign often prompts the search noise from forklift mast when lifting heavy loads. Noise is a symptom, and its character provides vital diagnostic clues. A silent mast under no load that groans or grinds under capacity points to specific issues.

Interpreting Different Sound Signatures

Not all noises are created equal. A trained ear can differentiate between several problems.

- Grinding or Growling: A continuous, harsh metallic sound often indicates direct metal-to-metal contact due to lubrication failure or severe contamination. The bearing rollers are scraping against degraded raceways.

- Clicking or Popping: A rhythmic sound that corresponds to roller rotation usually points to a damaged roller or a spalled raceway. As the damaged spot passes through the load zone, it creates a discrete impact noise.

- Squealing or Screeching: High-pitched sounds often stem from seal friction or, in some cases, insufficient lubrication where components are not sliding smoothly but rather experiencing stick-slip motion.

- Humming or Whirring: A constant, medium-pitched tone can sometimes be normal, but if it changes pitch with load or becomes noticeably louder, it may signal early-stage wear or slight misalignment.

When noise is reported specifically under heavy loads, it underscores that the bearing is deflecting under stress, allowing pre-existing damage to manifest. The increased force causes greater friction in worn areas and amplifies any clearances or inconsistencies. Immediate inspection is warranted. This focus on real-world performance issues feeds back into the product development cycle. By understanding common failure symptoms like noise under load, engineering teams at specialized centers can design bearings with enhanced rigidity, optimized internal clearances, and superior surface finishes to mitigate these problems, contributing to quieter, more reliable mast operation.

Advancements in Mast Bearing Technology and Future Trends

The world of mast bearings is not static. Continuous innovation drives improvements in longevity, capacity, and intelligence. Leading manufacturers are investing in several key areas to meet the future demands of automation and Industry 4.0.

Material Science and Surface Engineering

Beyond traditional chrome steel, advancements include the use of case-carburized steels for tougher, more impact-resistant bearing components. Sophisticated surface treatments like black oxide coating, phosphate coating, and advanced peening processes increase corrosion resistance and reduce surface stress concentrations, delaying the onset of fatigue.

Integrated Sensor Technology

The concept of the "smart bearing" is emerging. Embedding miniaturized sensors within the bearing housing to monitor temperature, vibration, and load in real-time allows for truly predictive maintenance. This data can be wirelessly transmitted to a fleet management system, alerting managers to a potential bearing issue before any noise or performance drop is noticeable to an operator.

Polymer and Composite Innovations

High-performance polymer cages are becoming more prevalent, offering advantages like reduced weight, inherent lubrication, and corrosion resistance. Similarly, composite materials are being explored for certain bearing elements to reduce inertia and improve performance in high-cycle applications.

This relentless pursuit of innovation is embodied by companies with a deep legacy in specialization. Jiangsu Wanda Special Bearing Co., Ltd, with its established Provincial Technology Center, is precisely the type of organization that drives this progress. By dedicating resources to exploit new products, design bearing functionality, and draft relevant technological standards, such entities ensure that the humble forklift mast roller bearing evolves in lockstep with the material handling industry's ever-growing challenges and opportunities.