Understanding the Basics of Combined Roller Bearings in Forklifts

When you aim to maximize the performance and durability of a forklift, understanding the role of a Forklift Combined Roller Bearing becomes essential. In many forklifts, wheels and axle assemblies must withstand heavy loads, frequent starts and stops, lateral forces, and sometimes harsh environments. A combined roller bearing is designed to offer robust load‑bearing capacity, handle both radial and axial loads, and provide smoother operation. Using the correct bearing type helps ensure that the forklift operates reliably under stress, reduces wear on components, and improves overall safety. In this section we explore what exactly a combined roller bearing is, and why it often outperforms simpler bearing types in industrial forklift applications.

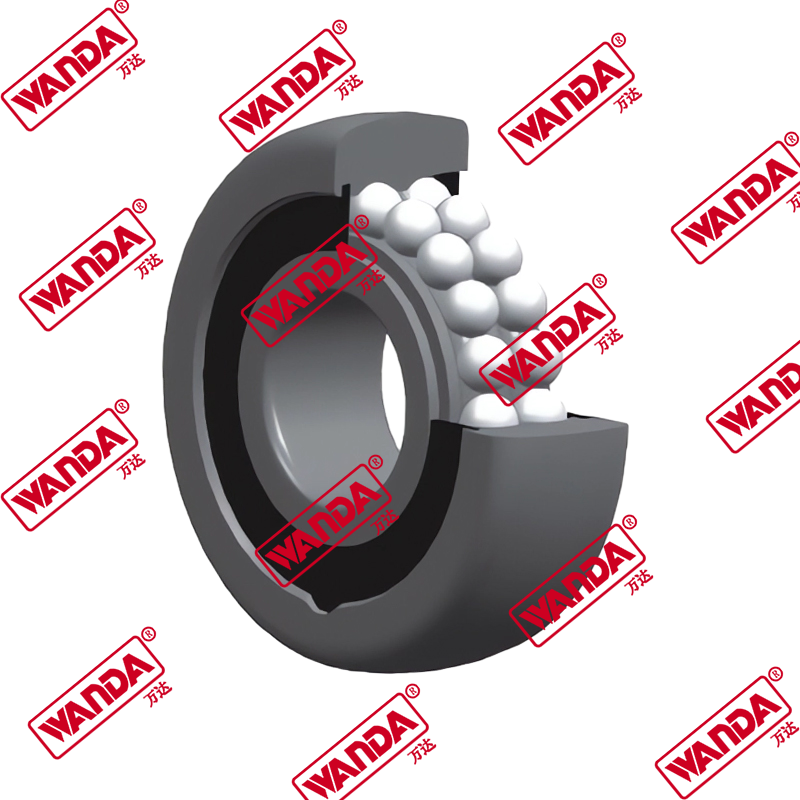

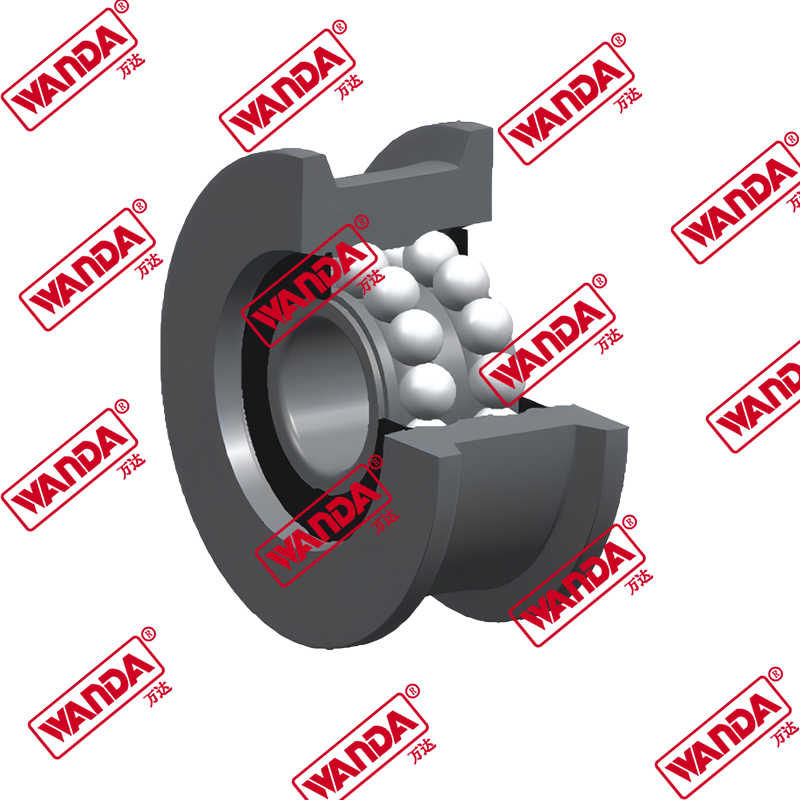

- What is a “Forklift Combined Roller Bearing”? — This type of bearing integrates multiple rolling elements (such as cylindrical rollers) and bearing races configured to handle both radial and thrust loads at the same time. In forklifts, this means the bearing supports the weight of the load and resists side or axial stresses that occur during turning or uneven loading.

- Key Advantages Compared to Other Bearing Types — Compared to simple ball bearings or plain bearings, combined roller bearings offer:

- Higher load capacity (both radial and axial).

- Improved durability under heavy or repetitive loads.

- Better alignment capabilities and smoother rotation under load.

- Reduced maintenance frequency and longer service intervals when properly installed and maintained.

How to Select the Right Bearing: Load, Dimensions, and Specifications

Interpreting “forklift combined roller bearing load capacity specifications”

Selecting an appropriate bearing for a forklift involves more than just matching a part number — you must interpret the load capacity specifications correctly. The term forklift combined roller bearing load capacity specifications refers to documented maximum radial loads, axial loads, and combined load ratings under certain operating conditions. For forklift operators and maintenance planners, understanding these specifications is critical to avoid overloading, premature failure, or safety hazards. Properly interpreting these values ensures the bearing can support both the static weight of the load and dynamic stresses from movement, turning, and uneven terrain.

- Check the manufacturer’s specified maximum radial load (the vertical load supported under static or moving conditions).

- Check the axial (thrust) load capacity — important when the forklift turns, shifts or lifts unevenly.

- Consider dynamic load ratings — real-world operations rarely remain static. Shock, vibration, and load swings require safety margins.

- Apply a safety factor based on usage: for frequent heavy-use forklifts, choose a bearing with load capacity 20–30% above expected maximum loads.

Matching Bearing Dimensions and Forklift Requirements

Beyond load ratings, the physical dimensions and geometry of a bearing must align with the forklift’s axle, wheel hub, and suspension setup. When using a Forklift Combined Roller Bearing, precise dimensional matching ensures correct load distribution, proper alignment, and safe operation. Failing to match diameters, widths, or bearing race geometry may cause uneven load, excess friction, misalignment, and premature wear — undermining the benefits of the combined roller bearing design. Therefore, it's vital to cross‑reference bearing dimension charts with forklift axle specifications before replacement or upgrade.

- Measure axle shaft diameter, hub bore diameter, and bearing seat width.

- Verify inner and outer diameter (ID/OD) tolerances match forklift design specs.

- Check bearing width and clearance — inadequate width can lead to overload; excess width may cause misalignment.

- Ensure correct bearing orientation and race alignment to handle both radial and axial loads properly.

Installation and Maintenance Best Practices

Step-by-step “forklift combined roller bearing installation procedure”

Proper installation of a combined roller bearing is as crucial as selecting the right one. A well-executed installation reduces risk of bearing failure, ensures optimal performance, and extends service life. The term forklift combined roller bearing installation procedure refers to the recommended step‑by‑step process to mount the bearing correctly in the forklift’s wheel hub or axle assembly. Skipping steps or improper handling — such as using excessive force, misaligning components, or neglecting lubrication — can lead to uneven load distribution, increased wear, overheating, or even catastrophic bearing failure. Below is a general, professional installation guideline for forklift combined roller bearings.

- Inspect all components (axle shaft, hub, bearing seat) for wear, corrosion, or damage before installation.

- Clean and deburr the shaft and hub bore to ensure a smooth fit.

- Align bearing correctly with respect to inner and outer races, ensuring correct orientation for both radial and axial load handling.

- Apply the appropriate industrial-grade grease or lubricant suited for heavy‑load forklift bearings.

- Press or seat the bearing using a proper hydraulic or mechanical press — avoid hammering directly on bearing races or rollers.

- After installation, rotate the wheel/hub assembly by hand to check for smooth motion and absence of binding or roughness.

- Re‑check torque on all related fasteners (hubs, axle nuts) to manufacturer recommended specs.

Recommended “forklift combined roller bearing maintenance schedule”

Once installed, regular maintenance is vital to ensure long-term performance and safety of a Forklift Combined Roller Bearing. A structured forklift combined roller bearing maintenance schedule helps detect early signs of wear, prevent unexpected downtime, and prolong bearing life. Maintenance frequency depends on usage intensity, load weights, and operating environment (e.g. dust, moisture, temperature). For heavy-duty forklifts in industrial environments, adopting a periodic inspection every few weeks or months — along with lubrication, cleaning, and load checks — can significantly extend bearing lifespan and reduce costly breakdowns.

- Inspect bearings visually once every month: look for discoloration, corrosion, or visible wear on housing and seals.

- Check lubrication levels regularly — top up or replace grease if contaminated or degraded.

- Monitor bearing temperature during operation: excessive heat may indicate overload, misalignment, or lubrication failure.

- Record vibration or noise levels — unusual vibrations or grinding noises may signal early bearing failure.

- Perform full bearing inspection (including bearing removal and internal roller/race inspection) every 6–12 months, depending on usage.

Identifying and Preventing Common Bearing Failures

“forklift combined roller bearing common failure causes” — What to watch out for

Even the best-quality bearing can fail prematurely if conditions are unfavorable. Understanding forklift combined roller bearing common failure causes is key for maintenance teams and forklift operators to proactively prevent damage and downtime. Frequent culprits include overload, improper installation, inadequate lubrication, contamination, and misalignment — situations that stress the bearing beyond its intended capacity or compromise its structural integrity. By being aware of these causes, maintenance crews can implement preventive measures and detect early warning signs before failures escalate into expensive repairs or safety hazards.

- Overloading — regularly operating beyond the bearing’s load capacity leads to excessive stress on rollers and races, causing deformation or cracking.

- Poor lubrication or contaminated lubricant — insufficient grease or use of wrong lubricant reduces lubrication film, accelerates wear, increases friction and heat.

- Misalignment or improper seating — if bearing inner or outer races are not perfectly seated, load distribution becomes uneven, causing edge stress.

- Environmental contamination — dust, water, chemical exposure or debris entering the bearing can damage rollers or races, leading to pitting or corrosion.

- Shock loads or abrupt impacts — sudden jolts, frequent starts/stops or rough terrain can cause fatigue or spalling on bearing surfaces.

How to Prolong Bearing Life and Prevent Downtime

Preventive practices and proper usage can greatly extend the lifespan of a Forklift Combined Roller Bearing. By combining correct installation, regular maintenance, load monitoring, and environmental protection, operators can mitigate many of the risk factors that lead to premature failure. Emphasizing preventive maintenance also reduces long‑term operating costs and enhances forklift reliability — key goals for any warehouse or industrial operation. Below are practical strategies to extend bearing life and minimize unplanned downtime.

- Ensure each bearing is chosen according to correct load capacity and forklift specifications.

- Follow the installation procedure strictly — use correct tools, alignment, lubrication, and torque settings.

- Implement the maintenance schedule without skipping inspections, lubrication checks, and cleaning.

- Protect bearings from contamination: use proper seals, shields, and keep operating environment clean.

- Monitor operational conditions — avoid abrupt overloads, heavy shock loads, and operate forklifts smoothly.

- Train operators and maintenance staff about warning signs (noise, heat, vibration) and encourage immediate inspection when detected.

Cost-benefit Analysis: Performance, Durability, and Lifespan

When evaluating whether to use a Forklift Combined Roller Bearing, many maintenance managers weigh up initial cost, installation complexity, maintenance requirements, lifespan, and overall performance benefits. Although combined roller bearings may have higher upfront cost compared to simpler bearings, their advantages — higher load capacity, longer lifespan, smoother operation, and reduced downtime — often justify the investment. Over time, fewer replacements, less maintenance labor, and improved forklift availability translate into lower total cost of ownership. In high‑usage or heavy‑load forklift applications, this cost‑benefit equation tends to favor combined roller bearings.

- Initial cost vs. lifespan — higher investment upfront, but longer service intervals reduce frequency and cost of replacements.

- Maintenance overhead vs. reliability — with regular maintenance, combined bearings reduce unexpected failures and downtime costs.

- Performance under load vs. safety & productivity — better load handling and smoother motion improve operational safety and efficiency.

- Total cost of ownership (TCO) — when factoring bearing costs, labor, downtime, and replacements over time, combined roller bearings often show superior long-term value.

FAQ

What is the difference between a combined roller bearing and a standard bearing for a forklift?

A combined roller bearing — referred to above as Forklift Combined Roller Bearing — is engineered to handle both radial (vertical/weight) and axial (side‑to‑side or thrust) loads simultaneously. Standard bearings (like simple ball bearings or plain bearings) often handle either radial or axial loads, or have limited capacity for one type. The combined design makes the bearing more versatile and robust, especially under the mixed stresses present in forklift operations (lifting heavy loads, turning, shocks, lateral forces). This dual-capability reduces wear, improves stability, and enhances safety compared to standard bearing solutions.

How often should a forklift bearing be inspected or re‑lubricated?

The inspection and lubrication frequency depends on usage intensity, load weights, and environmental conditions. For a forklift using a Forklift Combined Roller Bearing in a moderately busy warehouse, a good baseline is:

- Visual inspection: once per month — check for exterior wear, contamination, seal integrity.

- Lubrication check: every 1–3 months — ensure grease remains clean and at proper volume.

- Full internal inspection (bearing removal and roller/race examination): every 6–12 months, or sooner if the forklift is under heavy use or in harsh conditions.

These intervals align with a standard forklift combined roller bearing maintenance schedule. However, in heavy‑duty or high‑cycle operations, more frequent checks may be warranted to prevent unexpected bearing failure.

What are the signs that a forklift combined roller bearing may be failing?

Common warning signs include:

- Unusual noises — grinding, rumbling, or clicking during wheel rotation.

- Increased vibration or wobbling of wheels, especially under load or during turning.

- Excessive heat generated around the wheel hub or bearing housing after operation.

- Visible leakage of lubricant, or contamination (dust, metal particles) around bearing seals.

- Uneven wear on tires or forklift axles, indicating misalignment or uneven load distribution.

When any of these symptoms appear, it’s wise to remove and inspect the bearing internally — check rollers, races, lubricant condition — because they may indicate early stages of damage related to the common failure causes described earlier.

Is it worth upgrading to combined roller bearings if the forklift currently uses simple bearings?

In many cases, yes. Upgrading to a Forklift Combined Roller Bearing can significantly improve load capacity, durability, and reliability — especially for forklifts used in heavy‑load, high‑usage, or harsh environments. The investment typically pays off through fewer replacements, reduced maintenance downtime, smoother operation, and enhanced safety. Before upgrading, ensure that axle and hub dimensions match the bearing specifications, and follow correct installation procedures. For warehouses or operations where forklift reliability and uptime are critical, the upgrade often results in lower total cost of ownership over time, despite higher initial cost.