The operational efficiency and safety of any materials handling fleet hinge significantly on the quality and timely replacement of its forklift spare parts. A forklift is a complex machine, and the demanding environments in which it operates mean that various components, from simple filters to intricate hydraulic systems, are subject to constant wear and stress. Ignoring signs of degradation or opting for substandard parts can lead to catastrophic downtime, expensive repairs, and significant safety risks. This guide is crafted to offer fleet managers, maintenance professionals, and procurement specialists a professional, in-depth perspective on best practices for sourcing, selecting, and maintaining high-quality replacement parts, ultimately maximizing the lifecycle and performance of their lift trucks. We delve into specific wear components and system failures to provide actionable, expert advice that goes beyond basic maintenance schedules.

Navigating the Complexities of Forklift Spare Parts Sourcing

Sourcing the right forklift spare parts is often a trade-off between cost, availability, and quality. Fleet managers must be adept at evaluating these factors to ensure that short-term savings do not translate into long-term operational headaches. Understanding the differences between part types and the implications of choosing one over the other is crucial for maintaining a reliable fleet. The purchasing decision directly impacts the machine's safety compliance, warranty validity, and overall cost of ownership. Professional sourcing involves meticulous cross-referencing, understanding the machine's specific build, and forecasting future parts needs based on operational hours and environment.

OEM vs Aftermarket: A Critical Look at Forklift Component Selection

The debate between Original Equipment Manufacturer (OEM) parts and aftermarket alternatives is perpetual in the materials handling industry. OEM parts are manufactured by or for the original company, guaranteeing a perfect fit and material specification that matches the original design, often coming with a reliable warranty. This precision is essential for critical, high-stress components. However, their cost is typically higher, and availability can sometimes be delayed. Aftermarket parts, conversely, are produced by third-party manufacturers. While they often present a significant cost saving, their quality and adherence to original specifications can vary widely. A professional approach requires a nuanced selection, choosing OEM for safety-critical components like steering linkages or hydraulic cylinders, and perhaps considering high-quality, reputable aftermarket options for non-critical, high-wear items like filters or certain seals, provided thorough vetting is conducted. This strategic selection ensures both operational integrity and cost management.

- OEM Advantages: Guaranteed fit, factory-level performance, superior material quality, often backed by a comprehensive warranty.

- Aftermarket Advantages: Lower purchase price, wider range of suppliers, potentially quicker availability for common parts.

- Selection Strategy: Prioritize safety and system integrity; use OEM for load-bearing and control systems; consider quality aftermarket for consumables.

- Risk Mitigation: Always verify aftermarket suppliers' quality certifications and return policies before procurement.

When considering brake shoes, for example, the material composition and bonding strength are paramount for safety.

| Component Attribute | OEM Forklift Brake Shoes | Aftermarket Forklift Brake Shoes |

| Friction Material Consistency | High, meeting exact manufacturer specifications. | Variable, can range from excellent to poor. |

| Durability and Lifespan | Maximized longevity, designed for specific duty cycle. | Often reduced lifespan, leading to more frequent replacement. |

| Warranty Coverage | Typically included and robust. | Varies significantly; often minimal or non-existent. |

The Hidden Costs of Poor Quality Parts: Why Longevity Matters

The immediate savings offered by cheap, low-quality forklift spare parts are almost always offset by hidden, long-term costs. A substandard part fails prematurely, triggering another round of maintenance, procurement, and, critically, unplanned downtime. For components within a complex system, such as a transmission seal or a pump gasket, a single failure can lead to cascading damage across the entire assembly. This necessitates replacing major, expensive components that could have been saved by using the correct, high-quality part initially. Furthermore, poorly fitting or inferior parts can compromise the machine's performance, leading to higher fuel/energy consumption and reduced lifting capacity, which impacts overall fleet productivity. Fleet managers must calculate the Total Cost of Ownership (TCO) for parts, prioritizing reliability and longevity over the initial purchase price to maintain a lean and efficient operation. This includes factoring in labor time for re-work and lost productivity due to operational interruptions.

- Downtime Expense: Unplanned breakdowns directly halt operations, incurring significant costs in lost productivity and rescheduled work.

- Cascading Damage: A cheap seal failure can lead to internal component contamination, requiring full rebuilds of transmissions or engines.

- Increased Labor: Frequent part failures mean more hours spent on repetitive repairs rather than preventative maintenance.

- Safety Risk: Substandard brake or steering components pose an immediate and serious risk to operators and warehouse staff.

Deep Dive into Common Forklift System Failures and Parts Solutions

Understanding the specific failure modes of different forklift systems allows for targeted preventative maintenance and the precise sourcing of the correct forklift spare parts. System failures are rarely instantaneous; they are typically preceded by subtle symptoms that, if noticed and addressed early, can save significant repair costs. Professional maintenance teams focus on component lifespan forecasting, using operating conditions and hour meters to anticipate wear-out and schedule replacements proactively. This proactive approach is particularly critical for systems like electric motors and hydraulics, which are essential for the lift truck's primary functions. Being fluent in the diagnostics of these complex systems is a hallmark of an expert maintenance professional.

Mastering the Maintenance of Electric Forklift Motor Brushes Replacement Guide

Electric forklifts rely heavily on their DC or AC drive motors, and in DC motors, carbon electric forklift motor brushes replacement guide is a fundamental yet often overlooked maintenance task. The brushes conduct electricity between the stationary and rotating parts of the motor, and over time, friction causes them to wear down. Allowing brushes to wear past their recommended limit can lead to severe damage to the commutator or slip rings, turning a simple, inexpensive replacement into a costly motor rebuild. Regular inspection of the brush length and spring tension is crucial for maintaining efficient current transfer, which directly impacts the truck's speed and torque. A worn brush can cause sparking, overheating, and erratic performance, all detrimental to the motor’s health and the battery’s charge efficiency. Proper selection of replacement brushes, ensuring they are the correct grade of carbon for the motor's specifications, is essential for optimal conductivity and lifespan.

- Inspection Interval: Check brushes every 250-500 operating hours, depending on the duty cycle and manufacturer's recommendation.

- Critical Limit: Replace brushes before they reach the manufacturer’s minimum length to prevent commutator damage.

- Installation Tip: Ensure the new brush slides freely in the holder and the spring pressure is adequate for continuous contact.

- Post-Replacement: Monitor motor temperature and performance immediately after replacement to confirm proper seating.

Identifying the early warning signs of excessive brush wear can prevent major motor service.

| Symptom | Underlying Issue | Recommended Action |

| Visible excessive sparking (arcing) at the commutator. | Brushes worn too short or improper spring tension. | Immediate brush inspection and replacement; check commutator surface. |

| Loss of torque or reduced top speed. | Poor current transfer due to worn or stuck brushes. | Check brush length and ensure free movement in the brush holder. |

| Overheating of the motor casing. | Excessive resistance from poor brush contact or arcing. | Replace brushes; inspect the armature and field windings. |

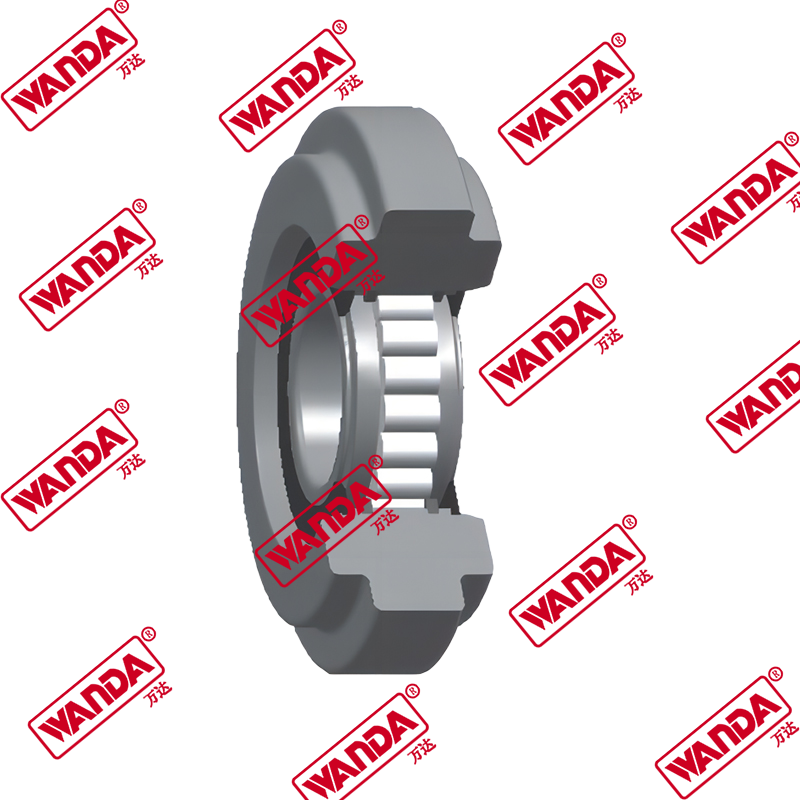

Diagnosing and Preventing Common Reasons for Forklift Hydraulic Pump Failure

The hydraulic system is the powerhouse of the forklift, responsible for lifting, tilting, and steering. The hydraulic pump is at its core, and understanding the common reasons for forklift hydraulic pump failure is paramount for minimizing downtime. The vast majority of pump failures stem from fluid contamination, which can be caused by external dirt ingress through worn seals or by internal contamination from component wear (metal shavings). Contaminated fluid acts as an abrasive, rapidly wearing down the pump’s internal gears, vanes, or pistons. Another significant cause is cavitation, which occurs when air enters the pump, often due to low fluid levels or leaks in the suction line. Cavitation creates damaging vapor bubbles that implode inside the pump, eroding metal surfaces. To maximize the life of this expensive forklift spare part, meticulous fluid cleanliness (using the correct filters and replacement schedule) and immediate attention to any external leaks are non-negotiable professional maintenance requirements.

- Contamination: Use high-quality, manufacturer-specified hydraulic fluid and replace filters religiously.

- Cavitation: Regularly check fluid reservoir levels and inspect all suction lines for air leaks.

- Overheating: Ensure the hydraulic fluid cooler is clean and functioning to prevent fluid breakdown.

- Alignment: For externally mounted pumps, verify that the drive coupling alignment is correct to prevent bearing strain.

A professional diagnosis can pinpoint the exact cause of a hydraulic pump issue, guiding the correct repair.

| Failure Cause | Symptom | Professional Solution |

| Fluid Contamination (Particulate) | Loud grinding noise; erratic or slow function. | Replace pump; flush the entire hydraulic system and replace all filters. |

| Cavitation (Air Ingress) | Pumping unit is exceptionally noisy (rattling/vibrating). | Locate and seal suction line leak; top off or replace fluid. |

| Seal/Gasket Failure | External leakage or internal bypass (loss of pressure). | Replace faulty seals; inspect fluid for emulsification or cross-contamination. |

Proactive Maintenance Strategies for Key Wear Parts

Effective fleet management shifts the focus from reactive repair to proactive maintenance, especially concerning high-wear forklift spare parts. Components like brakes, mast rollers, and starter solenoids are critical to safety and operation and have predictable failure curves based on usage. By adhering to a rigorous inspection schedule and replacing parts based on condition rather than failure, companies can drastically reduce unplanned service events. This section examines the longevity and selection aspects of these key wear items, providing professional guidance on condition monitoring and replacement timing. Employing condition-based monitoring, such as measuring friction material thickness or roller play, is a far superior approach to simply waiting for a component to fail mid-shift. This strategy requires trained technicians and a reliable inventory of quality forklift spare parts.

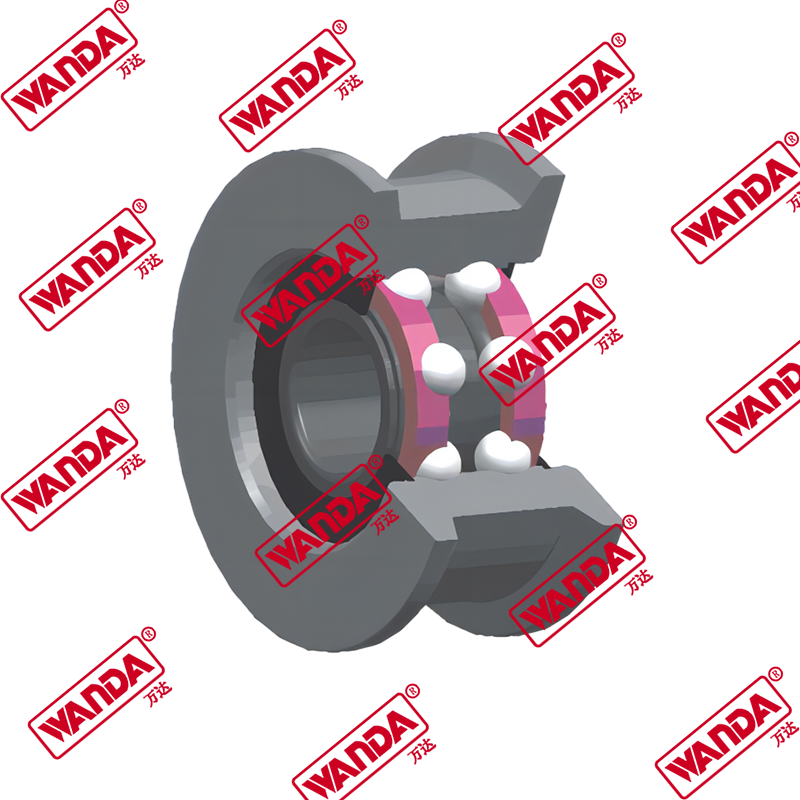

Evaluating Durability: OEM vs Aftermarket Forklift Brake Shoes Durability Comparison

Safety and stopping power are non-negotiable, making the OEM vs aftermarket forklift brake shoes durability comparison a high-stakes decision. As noted, the quality of the friction material and its bonding agent is the primary determinant of brake shoe lifespan and performance. OEM shoes are manufactured with materials rigorously tested to withstand the high temperatures and pressures of repetitive forklift braking cycles, offering a predictable, longer service life and consistent coefficient of friction throughout their wear. Aftermarket options, while cheaper, often use less robust materials that wear down faster or fail to maintain friction consistency, especially under heavy load or in damp conditions. While the initial cost saving of aftermarket shoes may seem appealing, the necessary increase in replacement frequency, coupled with the labor cost for each replacement, often makes the OEM option the more economical and certainly the safer choice in the long run. Professional procurement requires a comprehensive view of the lifecycle cost, not just the unit cost.

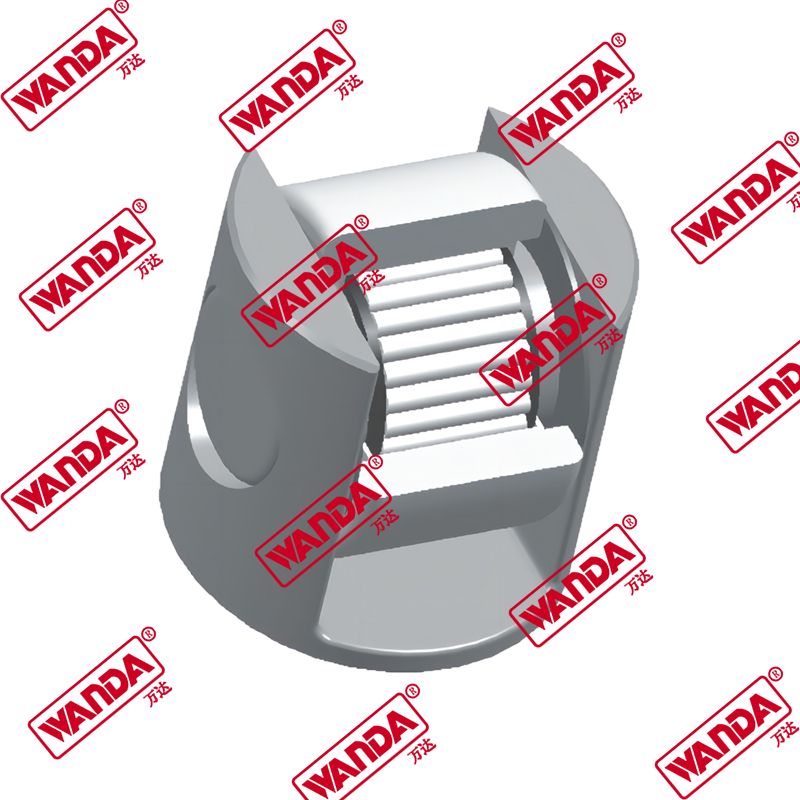

When to Service: How Often to Replace Forklift Mast Bearings and Rollers

The mast system bears the load and facilitates the vertical movement of the forks, making its components essential for safe operation. Knowing how often to replace forklift mast bearings and rollers is a key aspect of mast maintenance, though this is rarely a fixed time interval; it is typically condition-based. Mast bearings and rollers should be inspected during every scheduled preventative maintenance (PM) service, looking for signs of flat spots, excessive lateral or vertical play (slack), and damaged seals. Excessive play indicates worn bearings that can compromise mast stability, leading to load instability and potentially a dropped load. The operating environment heavily influences their life—dusty, abrasive conditions accelerate wear. Instead of a calendar schedule, professional maintenance relies on precise measurement of free play and careful visual inspection. Any roller that shows binding, excessive noise, or physical damage should be replaced immediately, and it is generally advisable to replace rollers and bearings in pairs or sets to ensure even load distribution and prevent uneven wear on the mast channels.

- Inspection Focus: Check for side-to-side (lateral) and front-to-back (heel-toe) movement of the mast channels.

- Lubrication: Follow the manufacturer’s specific lubrication recommendations; using the wrong grease can attract more dirt.

- Wear Sign: A "thunk" or noticeable shudder during lifting or lowering is a critical indicator of excessive roller play.

- Replacement Grouping: Always replace all related rollers/bearings on one stage of the mast to maintain even loading.

A structured inspection checklist ensures all critical areas of the mast assembly are evaluated.

| Inspection Area | Critical Condition Sign | Impact of Neglect |

| Roller Surface | Flat spots, pitting, or visible metal fatigue. | Increased friction; premature wear on the mast rails. |

| Bearing Seals | Cracked, missing, or extruded seals. | Loss of lubrication and ingress of abrasive dust/water. |

| Lateral/Vertical Play | Movement exceeding manufacturer specification (slop). | Load instability; risk of mast binding or structural failure. |

Troubleshooting Electrical Issues: Addressing Forklift Starter Solenoid Problems

The starter solenoid is a relatively inexpensive but vital component, acting as a high-current relay that connects the battery to the starter motor. Knowing how to perform basic troubleshooting forklift starter solenoid problems is a valuable skill for minimizing initial electrical downtime. Common solenoid failures include internal coil burnout, pitting of the internal contacts, or corrosion at the external terminals, all of which prevent the solenoid from closing the circuit and engaging the starter. If the operator turns the key and only hears a single, loud "click," this often indicates the solenoid coil is engaging, but the internal contacts are corroded or pitted and cannot pass the necessary high current to the starter motor. A professional troubleshooting sequence involves checking the battery voltage (the most common issue), then tracing the control circuit to the solenoid, and finally checking the high-current path. Replacement of this specific forklift spare part is usually straightforward, but proper terminal cleaning and tightening are non-negotiable to prevent future failures due to resistance and heat.

FAQ (Frequently Asked Questions)

What is the single most critical factor in choosing forklift replacement parts?

The single most critical factor in choosing forklift spare parts is ensuring specification accuracy and compatibility. This goes beyond merely matching the make and model; it involves verifying the part number against the specific Serial Number or Product Identification Number (PIN) of the lift truck, especially for internal components like engine, transmission, or hydraulic system parts. Different production years or regions may have slight variations in components that appear identical. A professional parts manager must consult the manufacturer’s parts manual, cross-reference the exact specifications (e.g., fluid capacity, pressure rating, material grade), and prioritize quality over cost for any part that is safety-critical or integral to a major system. Installing an incorrect part, even if it physically fits, can lead to immediate system failure, void warranties, and potentially compromise the machine's operational safety standards.

How does preventative maintenance on the electrical system affect overall lift truck lifespan?

Preventative maintenance (PM) on the electrical system—including batteries, cables, starters, and the electric forklift motor brushes replacement guide—profoundly affects the overall lift truck lifespan and operational efficiency. For internal combustion (IC) trucks, a robust electrical system ensures reliable starting, preventing excessive strain on the starter motor and battery. For electric trucks, PM is even more critical; proper battery maintenance (charging cycles, watering, cleaning terminals) is the primary determinant of the truck's overall lifespan, as the battery pack is the single most expensive component. Regular inspection of wiring harnesses for chaffing, cleaning high-current connections to reduce resistance and heat, and timely attention to components like the forklift starter solenoid problems prevent cascading failures. By reducing resistance and ensuring optimal power transfer, electrical PM maximizes the component efficiency, reduces thermal stress, and thereby extends the usable life of major, expensive assemblies.

Is it always necessary to replace a complete assembly when only a small component fails?

No, it is not always necessary to replace a complete assembly when only a small component fails, but the decision requires a professional cost-benefit analysis of repair versus replacement (R&R). For non-critical sub-assemblies, replacing a single, small forklift spare part (like a seal, a bearing, or a fuse) is often the most economical choice. However, for complex or high-stress assemblies—such as hydraulic cylinders, transmissions, or drive axles—the labor cost to fully disassemble, install the small part, reassemble, and test often exceeds the cost of a factory-remanufactured or new replacement assembly, which typically comes with a new warranty. When a failure is due to contamination or wear (e.g., internal damage from common reasons for forklift hydraulic pump failure), only replacing the small part often leaves the underlying cause or latent damage unaddressed, leading to a quick recurrence of the failure. Professionals prioritize assemblies when the small component failure has likely caused systemic damage, or when the R&R labor cost is disproportionately high.