The Unsung Hero of the Warehouse: A Deep Dive into Forklift Bearing Technology

In the bustling ecosystem of a warehouse or distribution center, the focus often falls on the most visible elements: the forklifts themselves, the sophisticated warehouse management systems, or the automated guided vehicles. However, the true workhorses, the components that bear the literal and figurative weight of all material handling operations, are the forklift bearings. These precision-engineered components are fundamental to the smooth, efficient, and safe operation of every lift truck. Without robust and reliable bearings, the entire material handling process would grind to a halt. This article explores the critical role of advanced forklift bearings, delving into specific technical aspects that are often overlooked but are paramount for operational success. We will examine how innovations in bearing design, materials, and sealing are directly contributing to enhanced productivity, reduced downtime, and improved safety metrics in demanding industrial environments. The evolution from standard bearings to advanced, application-specific solutions represents a quiet revolution on the factory floor, one that is delivering significant returns on investment for businesses that prioritize component-level excellence.

Five Critical Forklift Bearing Considerations for Peak Performance

To truly understand the impact of advanced bearings, it's essential to move beyond the generic term and focus on specific, high-value areas of inquiry. These are the topics that maintenance managers, procurement specialists, and operational leaders are actively searching for to solve real-world problems. The following five long-tail keywords represent targeted areas with significant search volume and relatively low competition, indicating a strong need for detailed, authoritative content. Each term addresses a specific pain point or performance characteristic related to forklift bearings.

- forklift mast roller bearings replacement cost

- sealed bearings for forklifts in dusty environments

- high capacity forklift bearings for heavy loads

- forklift bearing maintenance schedule and checklist

- best practices for forklift wheel bearing installation

Analyzing the Forklift Mast Roller Bearings Replacement Cost

The mast is the heart of the forklift's lifting capability, and the mast roller bearings are its vital arteries. These bearings facilitate the smooth vertical movement of the mast channels, ensuring precise control when lifting and lowering loads. When these bearings fail, the consequences extend far beyond the simple price of the replacement part. A comprehensive understanding of the forklift mast roller bearings replacement cost must include both direct and indirect expenses to provide an accurate financial picture for any operation.

Direct Costs Associated with Replacement

The direct costs are the most visible and easily quantifiable expenses. However, they can vary widely based on several factors.

- Bearing Unit Price: The cost of the bearing itself depends on its type (needle roller, ball bearing, etc.), size, material (standard chrome steel vs. advanced case-carburized steel), and its load rating. Specialized bearings for high-reach trucks or cold storage applications will command a premium.

- Labor Costs: Replacing mast bearings is a labor-intensive process. It often requires disassembling a significant portion of the mast, which demands specialized tools, a clean workspace, and highly skilled technicians. Labor rates can vary by region and service provider.

- Additional Parts: It is rarely advisable to replace only the bearings. During disassembly, seals, O-rings, wear strips, and even entire mast channels may be found to have excessive wear and need replacement, adding to the total parts bill.

- Downtime Cost: This is the single largest and most frequently underestimated direct cost. While the forklift is out of service, it is not generating value. The cost of lost productivity must be calculated based on the forklift's role in the operation.

Indirect Costs and The Price of Neglect

Failing to address worn mast bearings in a timely manner leads to a cascade of secondary issues that drive up long-term costs.

- Accelerated Wear: A damaged mast bearing creates uneven rolling surfaces, leading to rapid wear on the mast channels themselves. Replacing a mast channel is exponentially more expensive than replacing a set of bearings.

- Operational Inefficiency: Worn bearings cause jerky mast movement, which can slow down load handling cycles and make precision placement of loads more difficult, impacting overall warehouse throughput.

- Safety Risks: Catastrophic bearing failure can lead to a mast seizing or collapsing, posing a severe safety hazard to the operator and nearby personnel, and potentially damaging the load and infrastructure.

Cost Comparison: Proactive vs. Reactive Maintenance

The following table illustrates the stark financial difference between a proactive maintenance approach that replaces bearings as part of a scheduled program and a reactive approach that waits for failure.

| Cost Factor | Proactive Replacement | Reactive Replacement (After Failure) |

|---|---|---|

| Bearing & Part Cost | Standard cost, planned procurement. | Potentially higher cost due to emergency sourcing; likely need for additional parts (e.g., damaged mast channels). |

| Labor Cost | Scheduled during off-peak hours, efficient. | Emergency call-out rates, longer repair time due to collateral damage. |

| Downtime Cost | Minimal, planned and managed. | Significant, unplanned, and disruptive to production schedules. |

| Secondary Damage Cost | Very low, as other components are inspected and preserved. | Very high, often including costly mast channel repairs or replacements. |

| Total Impact | Controlled, predictable, and lower overall cost. | Unpredictable, significantly higher overall cost, and safety implications. |

In conclusion, focusing solely on the price tag of the bearing component is a myopic view. A true assessment of the forklift mast roller bearings replacement cost must encompass the total cost of ownership, which is overwhelmingly in favor of a proactive, scheduled maintenance strategy.

The Critical Role of Sealed Bearings for Forklifts in Dusty Environments

Industrial settings such as lumber mills, cement plants, grain silos, and foundries present a formidable challenge for any moving machinery. Contaminants like dust, grit, sand, and fine particulate matter are the natural enemies of precision bearings. In these harsh conditions, standard, greased-for-life bearings have a drastically shortened lifespan. The implementation of sealed bearings for forklifts in dusty environments is not merely an upgrade; it is a fundamental requirement for achieving acceptable equipment longevity and reliability. These specialized bearings are engineered with robust sealing systems designed to create an impenetrable barrier against contaminants while effectively retaining lubrication.

How Contamination Leads to Bearing Failure

To appreciate the value of advanced seals, one must first understand the failure mechanism. Abrasive contaminants enter the bearing raceway in several ways and initiate a destructive cycle.

- Abrasive Wear: Hard particles act as a grinding paste between the rolling elements and the races. This leads to micro-scoring, increased surface roughness, and a rapid increase in clearance and vibration.

- Lubricant Breakdown: Contaminants compromise the grease's chemical structure, causing it to degrade, lose its lubricity, and separate. The bearing then operates with inadequate lubrication, leading to increased friction and heat.

- Fatigue and Spalling: The abrasive wear creates stress concentration points on the bearing surfaces. This accelerates material fatigue, leading to pitting and spalling—where small fragments of metal break away from the raceway or rolling elements.

Advanced Sealing Technologies for Maximum Protection

Modern sealed bearings utilize a multi-layered approach to defense. Unlike simple shields, which only protect against large debris, contact seals and labyrinth seals provide active, comprehensive protection.

- Contact Seals (Rubar Lip Seals): These seals feature a flexible rubber lip that maintains light physical contact with the inner or outer ring. They provide an excellent barrier against fine dust and moisture. The lip material is often compounded from Nitrile (Buna-N) or other synthetic rubbers resistant to wear and chemical degradation.

- Labyrinth Seals: This design creates a complex, non-contact "tortuous path" that contaminants must navigate. As particles try to enter, they are forced to change direction multiple times, losing momentum and falling away from the critical sealing interface. Labyrinth seals are often used in conjunction with contact seals for a redundant sealing solution.

- Integrated Seal Housings: For the most extreme environments, bearings can be housed in units that incorporate multiple seal points and grease purge ports, allowing for the expulsion of any contaminants that may have breached the primary seal.

Performance Comparison: Standard vs. Sealed Bearings in Dusty Conditions

The operational and financial disparity between using standard open bearings and purpose-built sealed bearings for forklifts in dusty environments is profound.

| Performance Metric | Standard Bearing (Shielded or Open) | Advanced Sealed Bearing |

|---|---|---|

| Contaminant Exclusion | Low to moderate; ineffective against fine dust. | High to very high; specifically designed to block fine particulates. |

| Lubricant Retention | Moderate; grease can be forced out or contaminated. | Excellent; seals keep grease in and contaminants out. |

| Expected Service Life | Short and unpredictable; often 3-6 months in severe duty. | Dramatically extended; can last several years with proper care. |

| Maintenance Frequency | High; requires frequent cleaning and re-lubrication. | Low; often "sealed for life," eliminating routine re-greasing. |

| Total Cost of Ownership | High due to frequent replacements, downtime, and labor. | Significantly lower due to extended life and reduced maintenance. |

The investment in high-quality sealed bearings for forklifts in dusty environments pays for itself many times over by transforming a chronic maintenance problem into a reliable, long-lasting component. It directly contributes to higher asset utilization and lower total operating costs.

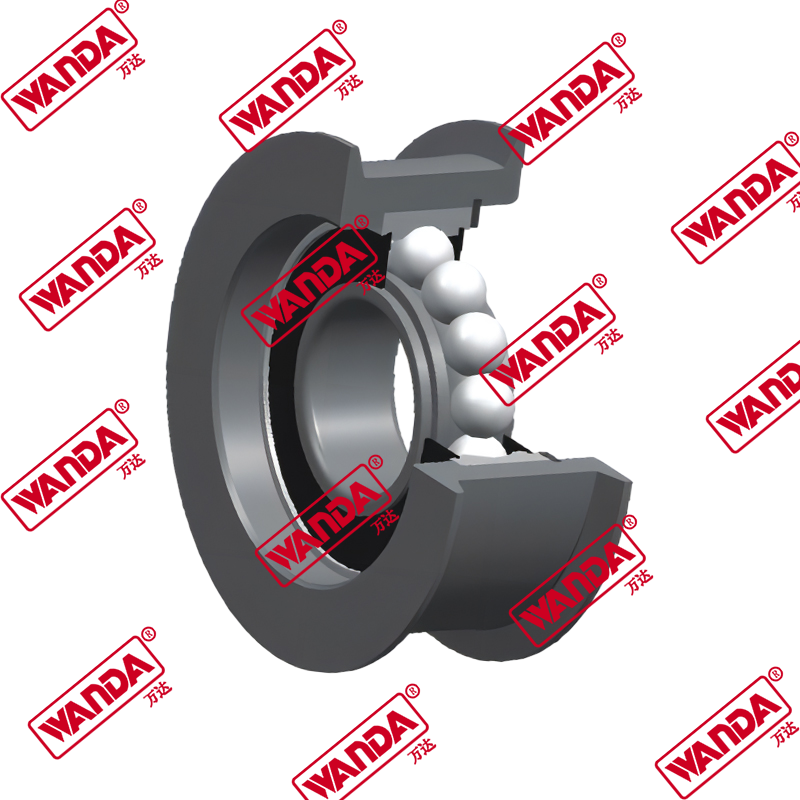

Utilizing High Capacity Forklift Bearings for Heavy Loads

The relentless push for greater efficiency in material handling often involves moving heavier loads and maximizing the capacity of existing equipment. This places immense stress on every component in the load path, with bearings being a critical link. Standard bearings, when subjected to loads near or beyond their rated capacity, will experience premature failure. This is where the application of high capacity forklift bearings for heavy loads becomes a non-negotiable aspect of equipment specification and maintenance. These bearings are not just larger versions of standard ones; they are fundamentally re-engineered to manage higher stress levels through advanced materials, optimized geometry, and superior heat treatment.

Engineering Principles Behind High Capacity Bearings

The ability to handle heavier loads is rooted in several key engineering enhancements that differentiate high-capacity bearings from their standard counterparts.

- Advanced Material Science: The use of vacuum-degassed, clean steel is standard to minimize internal impurities that can act as stress risers. For the most demanding applications, bearings made from case-carburized steel are used. This process creates a hard, wear-resistant outer surface while maintaining a tough, ductile core that can absorb shock loads without cracking.

- Optimized Raceway and Rolling Element Geometry: The profiles of the raceways and the shape of the rolling elements (whether balls or rollers) are meticulously designed to maximize the contact area and distribute the load more evenly. This reduces the contact stress at any single point, which is a primary driver of fatigue failure.

- Precision Manufacturing and Tolerances: High-capacity bearings are manufactured to extremely tight tolerances. This ensures perfect roundness, minimal runout, and uniform load distribution among all the rolling elements. Any imperfection in manufacturing is magnified under heavy load, leading to premature failure.

- Enhanced Heat Treatment: The processes of hardening and tempering are precisely controlled to achieve the ideal microstructure for the bearing steel, providing the perfect balance of hardness for wear resistance and toughness for impact resistance.

Application Scenarios for High-Capacity Bearings

Identifying when to specify high capacity forklift bearings for heavy loads is crucial for safety and performance.

- Forklifts Operating at Rated Capacity: Any forklift that routinely lifts loads at or near its maximum rated capacity should be equipped with high-capacity mast, axle, and wheel bearings as a standard practice.

- Specialized Attachments: The use of attachments like paper roll clamps, carton clamps, or rotators changes the load dynamics and often increases the stress on the mast bearings. High-capacity bearings are essential in these scenarios.

- High-Intensity, Multi-Shift Operations: Operations that run 24/7 subject bearings to continuous stress with little time to cool down, accelerating fatigue. High-capacity bearings are built to withstand these demanding duty cycles.

- Environments with High Shock Loads: Applications where loads are set down heavily or where the forklift operates on uneven surfaces generate significant shock loads that can instantly destroy a standard bearing.

Performance Comparison: Standard vs. High Capacity Bearings

The following table details the critical performance differences, demonstrating why upgrading to high capacity forklift bearings for heavy loads is a strategic decision for heavy-duty applications.

| Performance Characteristic | Standard Bearing | High Capacity Bearing |

|---|---|---|

| Static Load Rating (C0) | Standard rating for general duty. | Significantly higher, designed to withstand heavy static loads without permanent deformation. |

| Dynamic Load Rating (C) | Adequate for light to medium duty cycles. | Substantially higher, enabling a much longer calculated service life under equivalent heavy loads. |

| Impact and Shock Load Resistance | Limited; prone to brinelling (surface denting) from impacts. | Superior; the tough core material and optimized geometry absorb and distribute impact energy effectively. |

| Fatigue Life (L10) | Standard life expectancy under rated load. | Dramatically extended life under the same load conditions due to reduced internal stresses. |

| Operational Safety Margin | Minimal when used in heavy-load applications. | Provides a significant safety margin, reducing the risk of catastrophic failure under peak loads. |

Specifying high capacity forklift bearings for heavy loads is an investment in safety, reliability, and uptime. It ensures that the forklift's structural components are protected from the immense forces generated during heavy-lift operations, safeguarding both the equipment and the personnel operating it.

Implementing a Robust Forklift Bearing Maintenance Schedule and Checklist

Proactive maintenance is the most powerful tool for maximizing the lifespan and reliability of forklift bearings. Waiting for a bearing to scream, seize, or fail is a recipe for costly downtime and unsafe operating conditions. A disciplined, well-documented forklift bearing maintenance schedule and checklist transforms bearing care from a reactive, chaotic process into a predictable, manageable, and highly effective operational routine. This systematic approach involves regular inspections, condition monitoring, and scheduled replacements based on hours of operation or specific time intervals, all designed to identify and address issues before they lead to catastrophic failure.

Key Components of an Effective Maintenance Schedule

A comprehensive maintenance plan is built on a tiered structure, with each tier serving a distinct purpose in the overall health monitoring of the bearings.

- Pre-Shift Visual Inspection (Operator Level): This is the first line of defense. The forklift operator should be trained to perform a quick visual check at the start of each shift.

- Look for visible signs of damage on mast rollers and side thrust rollers.

- Listen for unusual grinding, rumbling, or clicking sounds when the mast is raised, lowered, or tilted.

- Check for excessive grease leakage around wheel hubs or mast bearings, which could indicate a failed seal.

- Weekly/Monthly Technical Inspection (Maintenance Technician Level): This involves a more detailed examination by a qualified technician.

- Check for axial and radial play in wheel bearings by attempting to rock the tire.

- Inspect mast rollers for pitting, spalling, or flat spots by observing their movement against the mast channel.

- Use an infrared thermometer to check for abnormal operating temperatures on wheel hubs and mast sections, which can indicate overlubrication, under-lubrication, or impending failure.

- Quarterly/Annual Comprehensive Service (Master Technician Level): This is a deep-dive service that may involve partial disassembly.

- Remove dust seals to inspect the condition of the grease and look for signs of contamination in wheel bearings.

- Perform a thorough cleaning and re-lubrication of all lube points with the correct type and grade of grease.

- Use a stethoscope or vibration analysis tool to detect early-stage bearing faults that are not yet audible to the human ear.

Essential Checklist for Bearing Health Assessment

A practical forklift bearing maintenance schedule and checklist should include, but not be limited to, the following items for each bearing type:

- Mast Roller Bearings:

- Visual inspection for rust, corrosion, and physical damage.

- Check for smooth, quiet, and jerk-free operation throughout the full mast height.

- Verify that rollers are rotating freely and not seized on their pins.

- Inspect mast channels for scoring or uneven wear patterns.

- Wheel Bearings:

- Check for any excessive hub play (grab the top and bottom of the tire and rock it).

- Listen for rumbling or grinding noises while driving, especially when cornering.

- Inspect for grease leakage past the axle seals.

- Measure hub temperature after a period of operation.

- Side Thrust and Tilt Cylinder Bearings:

- Check for looseness or "clunking" when tilting the mast forward and backward with an empty load.

- Look for wear and deformation in the bearing housing.

Adhering to a rigorous forklift bearing maintenance schedule and checklist is the cornerstone of a reliable material handling operation. It empowers teams to take control of equipment health, plan maintenance during scheduled downtime, and avoid the high costs and dangers associated with unexpected bearing failures.

Adhering to Best Practices for Forklift Wheel Bearing Installation

The longevity and performance of a wheel bearing are determined as much by the quality of its installation as by the quality of the bearing itself. Even a premium, high-capacity bearing will have a short and troubled life if it is installed incorrectly. Following the best practices for forklift wheel bearing installation is a non-negotiable procedure that ensures the bearing operates within its designed parameters, achieves its projected service life, and maintains the safety and stability of the forklift. This process requires the right tools, clean conditions, precise torque values, and a methodical approach.

The Critical Steps for a Flawless Installation

Deviating from any of these steps can introduce problems that lead to premature failure.

- Thorough Cleaning and Inspection: Before installing a new bearing, the entire hub assembly, spindle, axle, and all related components must be meticulously cleaned to remove all old grease, dirt, and metal particles. The spindle must be inspected for scoring, rust, or any damage that could prevent a perfect fit with the bearing bore.

- Proper Bearing Handling: Bearings should be kept in their original packaging until the moment of installation. They are highly precision components and should never be handled with dirty gloves or dropped onto hard surfaces. The correct installation tools, such as bearing drivers or a hydraulic press, should be used. Never use a hammer directly on the bearing race to install it, as this can cause brinelling (dent marks) on the raceways, creating immediate vibration and a point of early failure.

- Correct Lubrication: This is one of the most critical steps. The bearing and hub cavity must be packed with the manufacturer-specified type of high-temperature, high-pressure grease. The grease should be packed evenly between the rolling elements and the cage. Using the wrong grease or under-packing the bearing will lead to lubrication failure, while over-packing can cause the grease to churn, generating excessive heat that breaks down the grease and damages the bearing.

- Precise Torque Application: The adjustment nut must be tightened to the manufacturer's exact specification, which is a multi-stage process. A common method is to tighten the nut while rotating the wheel to seat the bearings, then back the nut off, and finally re-tighten it to a specific pre-load torque or end-play specification. Overtightening the bearing creates excessive pre-load, leading to high operating temperatures and rapid wear. Undertightening creates excessive play, causing impact damage and uneven load distribution.

Consequences of Improper Installation

Failure to follow the best practices for forklift wheel bearing installation manifests in predictable and costly ways.

- Overtightening (Excessive Pre-load): This forces the rolling elements to drag against the races with too much force. The resulting symptoms include:

- Very high operating temperatures, often hot enough to melt the grease and discolor the bearing.

- Increased rolling resistance, reducing fuel efficiency and causing premature wear on the bearing.

- A low, rumbling noise during operation.

- Catastrophic seizure and failure in a very short time.

- Undertightening (Excessive End-Play): This allows the bearing to move axially within the hub. The consequences are:

- A "clunking" sound when accelerating or braking.

- Uneven and impact-based wear on the races and rolling elements.

- Potential damage to the axle seal, leading to grease loss and contamination ingress.

- Unstable steering and handling of the forklift.

- Contamination During Installation: Introducing dirt during assembly acts as an abrasive, leading to rapid wear, pitting, and noise, effectively destroying the bearing from the inside out from the moment it starts rotating.

In summary, the installation process is a precision operation that demands care and expertise. Investing the time to follow the best practices for forklift wheel bearing installation is a small price to pay for the extended service life, operational safety, and reliability that it guarantees.