For over five decades, since our establishment in 1969, Jiangsu Wanda Special Bearing Co., Ltd. has been at the forefront of specialized bearing technology. As a high-tech company with a Provincial Technology Center and advanced production lines, we are dedicated to researching, designing, and producing high-performance bearings for industrial applications. This deep expertise is directly applied to critical components like the forklift chain sheave, a pivotal element in the mast system of forklifts. This comprehensive guide will delve into the function, selection, and maintenance of this essential component, ensuring your operations run smoothly and efficiently.

Understanding the Forklift Chain Sheave

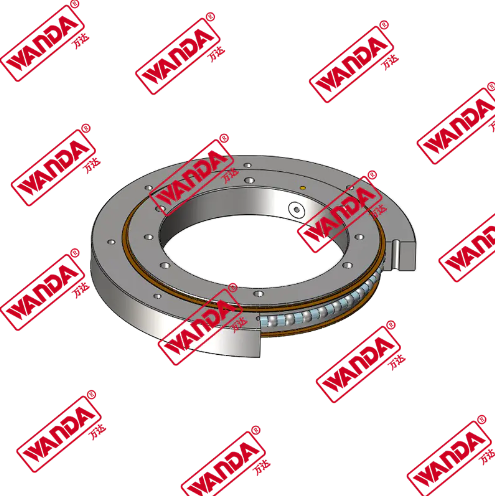

A forklift chain sheave is a grooved wheel, typically mounted on bearings, that guides and supports the lift chain in a forklift's mast assembly. Its primary role is to redirect the force from the hydraulic cylinder, via the chain, to raise and lower the forks. A high-quality sheave ensures smooth chain movement, minimizes wear, and contributes to the overall stability and safety of the lifting operation.

Why a Specialized Sheave Matters

- Precision Engineering: Ensures perfect alignment with the lift chain.

- Reduced Friction: High-grade bearings and surface treatments minimize energy loss and heat generation.

- Enhanced Durability: Manufactured from robust materials to withstand immense tensile loads and shock loads.

- Operational Safety: A failed sheave can lead to catastrophic mast failure, making quality non-negotiable.

In-Depth Analysis: Your Forklift Chain Sheave Questions Answered

how to measure a forklift chain sheave

Accurate measurement is critical for a perfect replacement. Using incorrect dimensions can lead to rapid chain wear and potential system failure.

Key Measurement Parameters

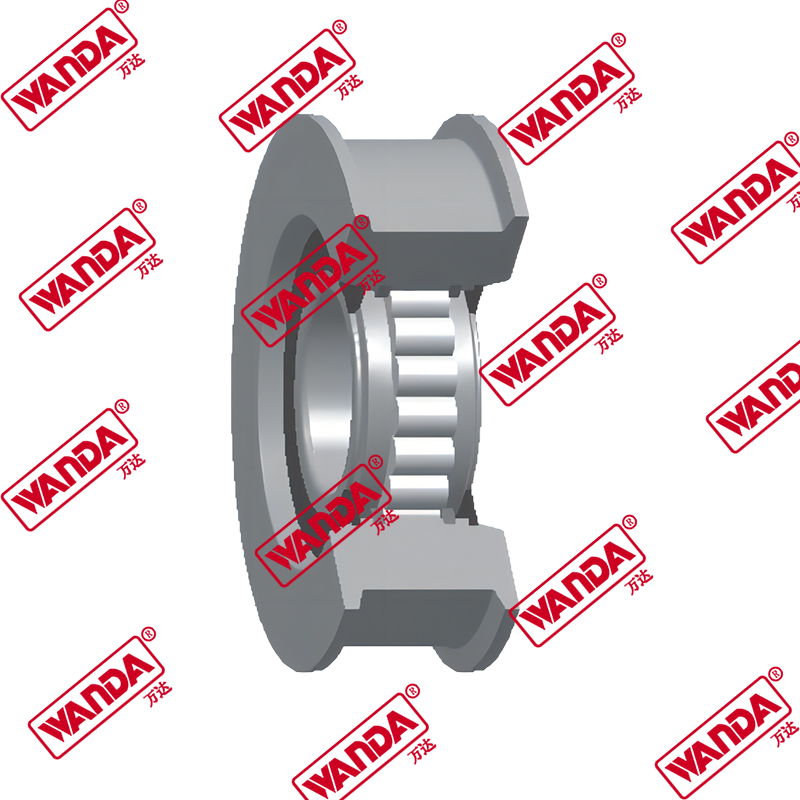

- Outside Diameter (OD): The overall diameter across the sheave.

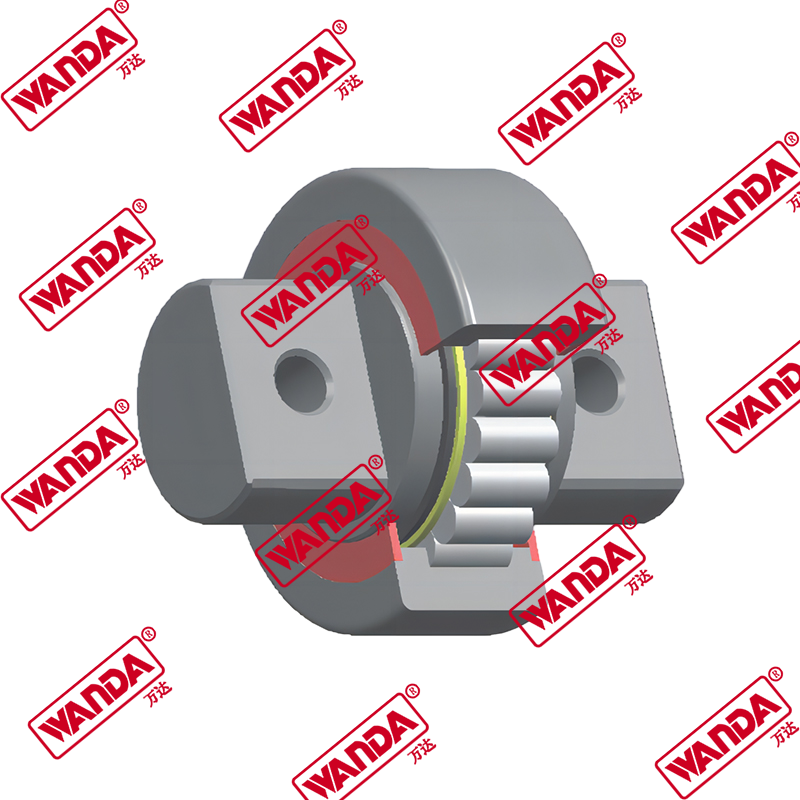

- Bore Diameter: The inner hole size where the sheave mounts onto the shaft or bearing.

- Groove Profile: The shape and dimensions of the groove must match the chain precisely.

- Keyway Size (if applicable): Width and depth of the keyway that secures the sheave.

It is crucial to measure the worn sheave carefully, as wear can alter the original dimensions. For instance, a sheave with a worn groove will have a larger effective pitch diameter than a new one, which can cause the chain to ride improperly.

signs of a worn forklift chain sheave

Proactive identification of wear can prevent costly downtime and safety hazards. Regular inspection is a key part of preventative maintenance.

Visual and Auditory Indicators

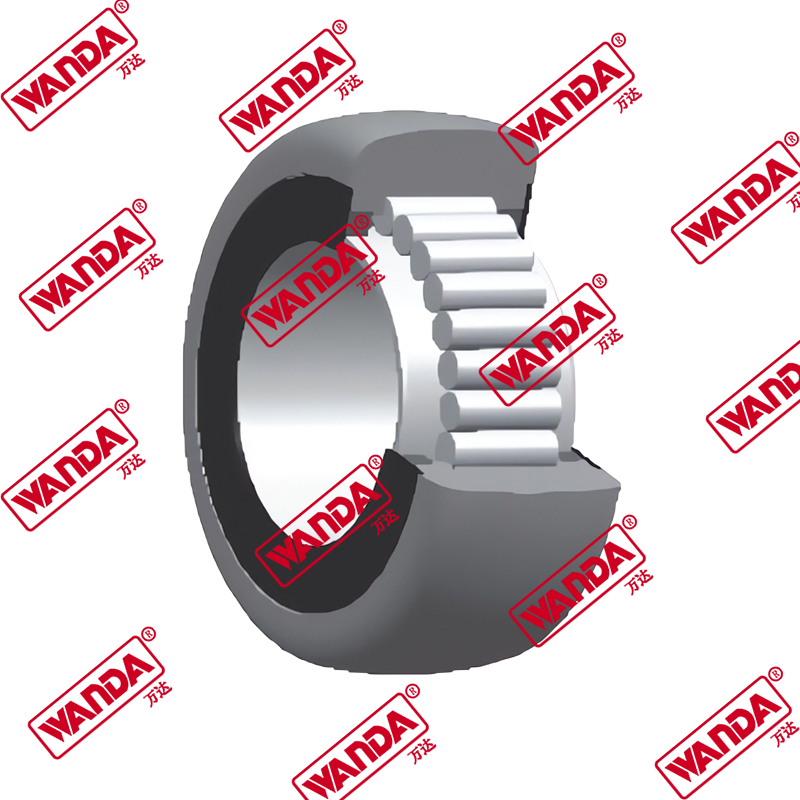

- Visible Groove Deformation: The groove becomes hooked, uneven, or develops a "W" shape.

- Cracks or Chips: Any physical damage to the sheave body is a red flag.

- Excessive Chain Noise: Grinding, squealing, or rattling sounds during operation.

- Uneven Fork Movement: The forks may jerk or not lift smoothly.

Comparing a new sheave to a severely worn one reveals a significant difference in groove shape. A new sheave has a clean, U-shaped groove that cradles the chain, whereas a worn sheave has a distorted groove that fails to support the chain links properly, leading to accelerated wear on both components.

forklift mast sheave vs roller differences

While both are mast components, sheaves and rollers serve distinct purposes. Understanding their roles is key to proper maintenance and troubleshooting.

| Feature | Forklift Chain Sheave | Mast Roller |

| Primary Function | To guide and redirect the lift chain. | To guide the mast channels, ensuring smooth vertical movement. |

| Interaction | Direct contact with the lift chain. | Direct contact with the mast rails or channels. |

| Load Type | Handles high tensile loads from the chain. | Handles radial and side loads from mast movement. |

| Common Wear | Groove wear, bearing failure. | Surface wear, flattening, bearing seizure. |

The fundamental difference lies in their interaction: a sheave is designed for a chain, while a roller is designed for a flat or angled surface. Using a worn roller can cause mast binding, whereas a worn sheave directly affects chain performance and lift height.

best material for forklift chain sheave

The material choice directly impacts the sheave's lifespan, noise level, and resistance to wear.

Common Material Options

- High-Strength Alloy Steel: Offers superior strength and durability for heavy-duty applications.

- Case-Hardened Steel: Provides a hard, wear-resistant surface with a tough, shock-absorbing core.

- Nylon/Polyamide: Lightweight, quiet, and corrosion-resistant, but may not suit the highest load capacities.

The choice between materials involves a trade-off. For example, a case-hardened steel sheave will generally have a much longer service life under high-load conditions compared to a nylon sheave, but the nylon sheave will operate more quietly and is immune to rust.

forklift chain sheave replacement cost

The cost of replacement is not just the part itself; it encompasses several factors that can influence the total investment.

Cost Breakdown Factors

- Sheave Quality: Premium sheaves from specialized manufacturers may have a higher upfront cost but offer better longevity.

- Forklift Model: Sheaves for larger, high-capacity forklifts are typically more expensive.

- Labor: The complexity of the mast disassembly required for replacement affects labor hours.

- Additional Parts: It is often recommended to replace the chain and bearings simultaneously.

Investing in a high-quality sheave from a specialist like Jiangsu Wanda can lead to lower total cost of ownership. While the initial price might be higher, the extended service life and reduced risk of collateral damage to the chain and mast result in significant long-term savings compared to frequently replacing inferior parts.

Expert Maintenance Tips for Long-Lasting Sheaves

Proper care extends the life of your forklift chain sheave and the entire lifting system.

- Conduct regular visual inspections for the signs of a worn forklift chain sheave.

- Ensure proper lubrication of the chain to reduce friction transferred to the sheave.

- Keep the mast clean from debris that could become embedded in the sheave groove.

- Always verify correct alignment after any replacement or mast work.

Frequently Asked Questions (FAQ)

1. How often should I inspect my forklift chain sheave?

We recommend a visual inspection during weekly pre-operation checks. A more thorough inspection should be part of your scheduled preventative maintenance, typically every 250-500 hours of operation, or as specified by the forklift manufacturer.

2. Can I replace just one sheave, or should I replace them in pairs?

It is highly advisable to replace sheaves in pairs (or sets, depending on the mast design). If one sheave is worn, its counterpart is likely similarly aged and worn. Replacing only one can lead to uneven chain pull and accelerated wear on the new component.

3. What happens if I ignore a worn-out sheave?

Ignoring a worn sheave can lead to a snapped lift chain, sudden dropping of the load, mast mechanism failure, and pose a severe safety risk to personnel and equipment. The cost of reactive repair is always far greater than proactive replacement.

4. Is the sheave bore size standardized?

No, the bore size is not standardized across all forklift models. This is why knowing how to measure a forklift chain sheave accurately is so important. Always refer to the OEM specifications or measure the existing component precisely.

5. Why is the groove profile so important?

The groove profile is engineered to match the specific chain link design. An incorrect profile will cause point loading on the chain, dramatically increasing wear rates on both the chain and the sheave, and can lead to chain derailment.