1. Enhancing Forklift Reliability: Tackling Friction Challenges in Mast Operation

1.1 Friction and Wear Impact Forklift Performance

During the lifting and lowering of forklift masts, constant contact between the mast and guide rails causes significant friction. This friction leads to wear and tear of critical components, vibration, and noise, which collectively degrade operational accuracy and stability.

1.2 High-Frequency Use Exacerbates Component Degradation

In environments with frequent lifting cycles and heavy loads, friction and wear accelerate, increasing equipment failure rates. This results in more frequent maintenance needs and costly downtime, directly affecting warehouse productivity.

1.3 Complex Work Conditions Amplify Friction Effects

Forklifts operating in harsh or cluttered industrial environments experience intensified friction challenges. Such conditions hasten the deterioration of mast components, risking equipment reliability and disrupting workflow efficiency.

2. Advanced Design Solutions: How Forklift Mast Guide Rollers Revolutionize Performance

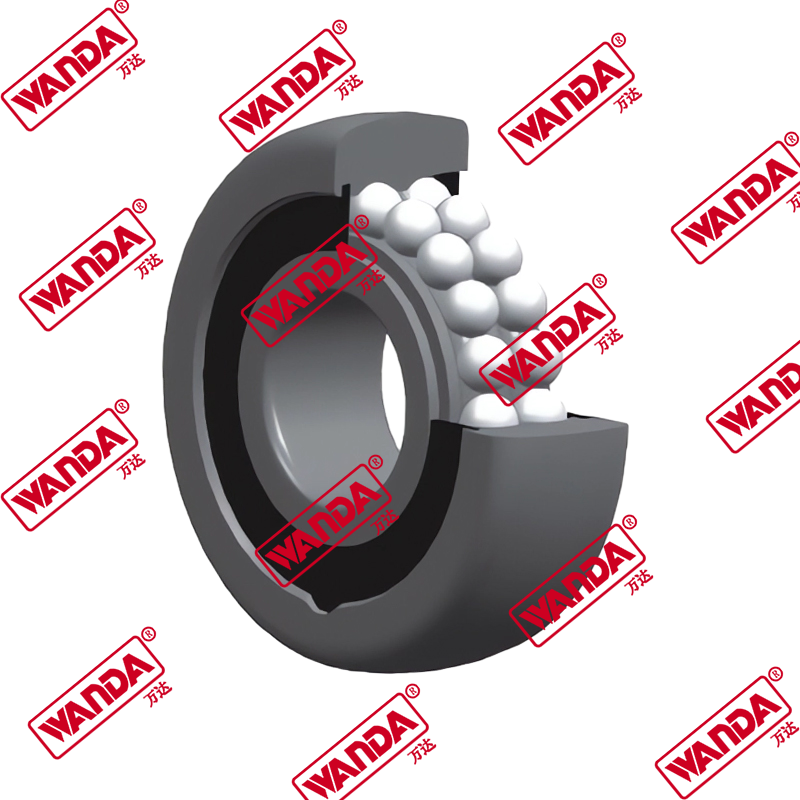

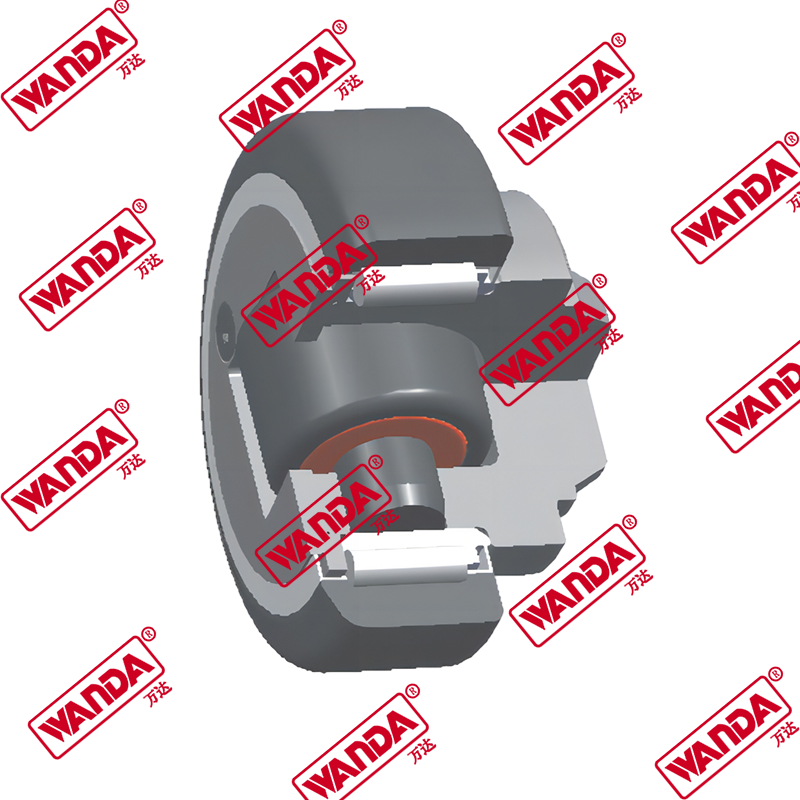

2.1 Precision Engineering Reduces Contact Friction

Forklift Mast Guide Rollers feature optimized roller structures that minimize the contact area between the mast and guide rails, effectively lowering friction coefficients and ensuring smoother mast movement during lifting operations.

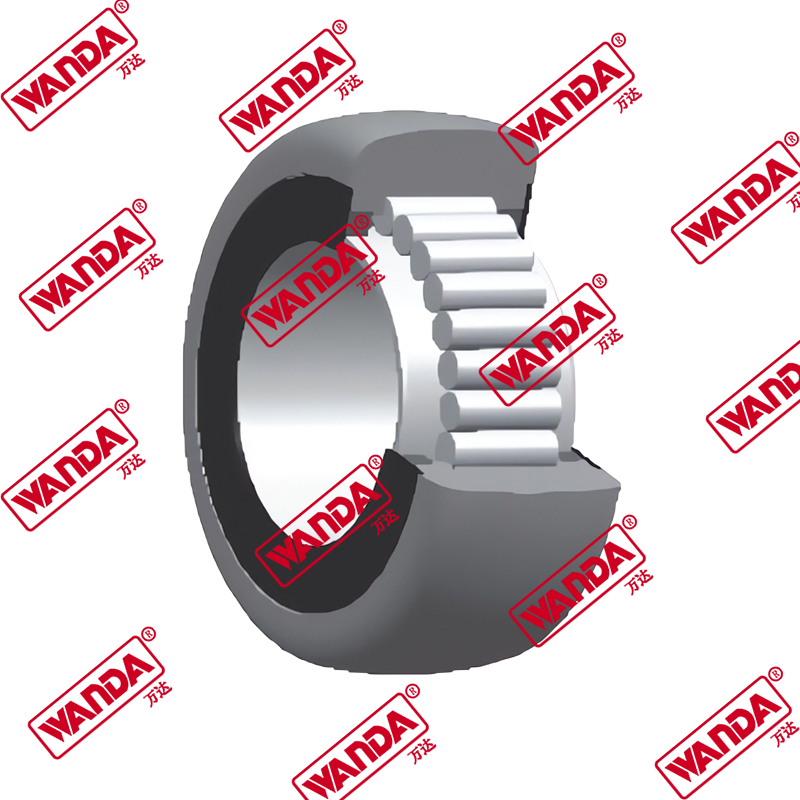

2.2 Use of Durable, High-Quality Materials Enhances Wear Resistance

Constructed from premium materials with exceptional hardness and thermal resistance, these rollers withstand high pressure and heat generated by friction. This durability safeguards both the rollers and guide rails from premature wear in demanding conditions.

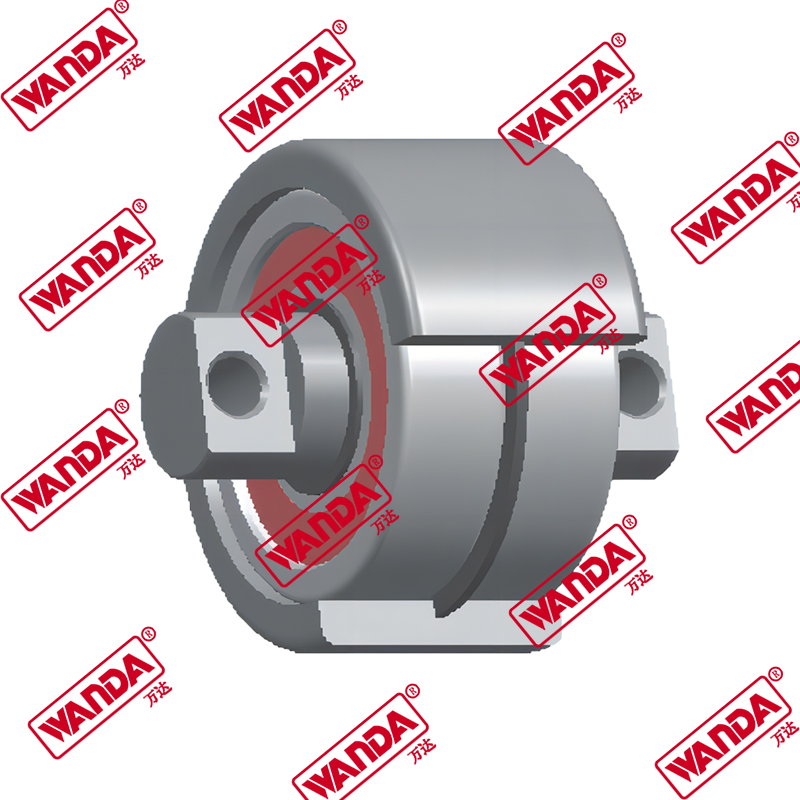

2.3 Stable Operation Under Long-Term and Complex Conditions

The combination of innovative design and material excellence ensures that forklifts equipped with these guide rollers maintain operational stability and precision, even in continuous, high-intensity industrial use.

3. Operational Benefits: Increasing Efficiency, Reducing Downtime, and Extending Equipment Life

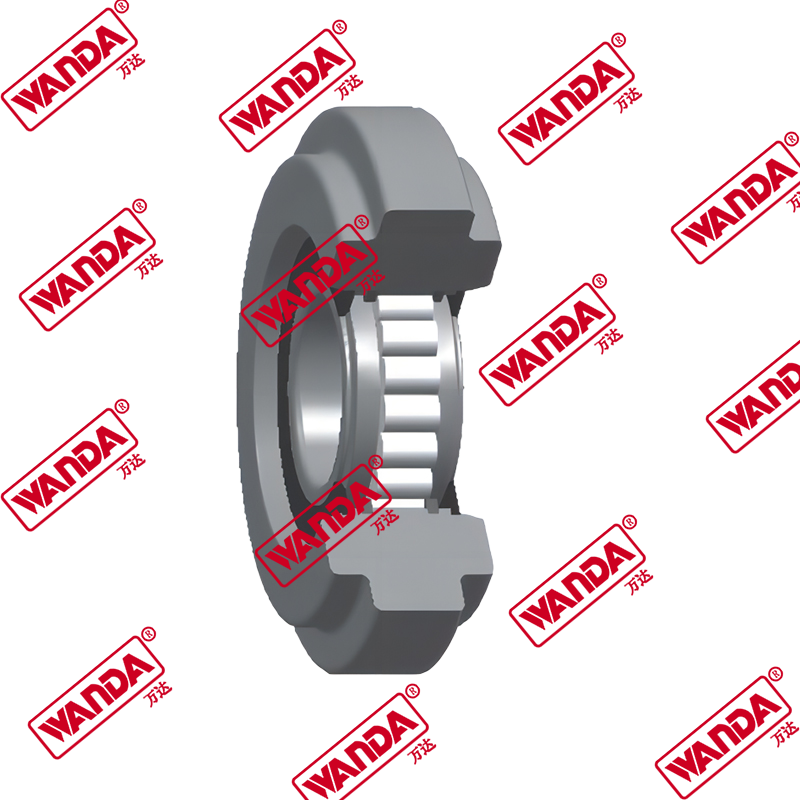

3.1 Smoother Mast Movement Boosts Productivity and Accuracy

By significantly reducing friction, Forklift Mast Guide Rollers enable smoother mast lifting and lowering, minimizing vibration and noise. This enhances operational precision and raises overall handling efficiency.

3.2 Critical Performance in High-Intensity Work Environments

In rigorous industrial settings with heavy load demands, these guide rollers prevent heat buildup and component instability. This reduces wear and maintains forklift reliability during continuous and intense operations.

3.3 Lower Maintenance Costs and Increased Equipment Uptime

Reduced friction correlates directly with decreased mechanical wear, leading to fewer breakdowns and longer service life for forklift components. Enterprises benefit from lower repair expenses and improved production continuity, optimizing operational workflows.