1. Forklift Slewing Bearing: Foundation for Enhanced Stability in Complex Operations

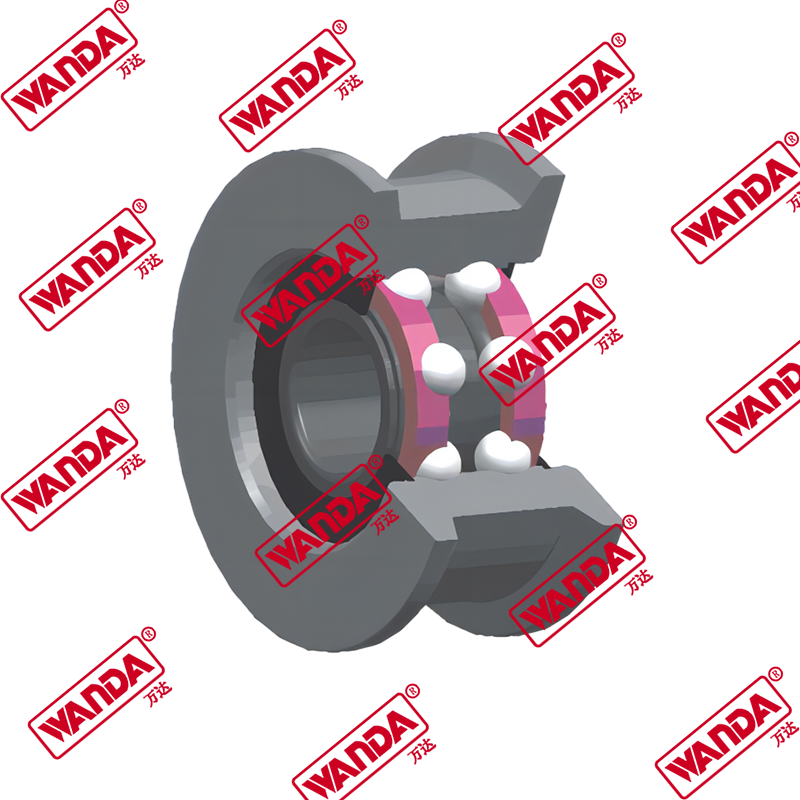

1.1 Critical Role in Heavy Load Stability

Forklift Slewing Bearings are essential in maintaining the forklift’s stability, particularly when handling heavy objects. By dispersing multidirectional pressure, these bearings prevent tilting and instability even under extreme load conditions, ensuring operator safety and operational smoothness.

1.2 Prevention of Operational Risks Through Structural Balance

Through precise engineering, the slewing bearing optimizes balance, preventing forklift overturns or jams caused by uneven loads or external forces. This is especially vital during stacking or transporting bulky items where multi-directional forces act simultaneously.

1.3 Maintaining Stability Across Diverse Work Environments

As forklifts operate in increasingly complex and varied settings, the slewing bearing adapts to shifting pressures, ensuring consistent platform steadiness across narrow aisles, uneven terrain, and congested warehouses, thus safeguarding efficient workflow.

2. Reducing Wear and Maintenance: Slewing Bearings Boost Forklift Longevity

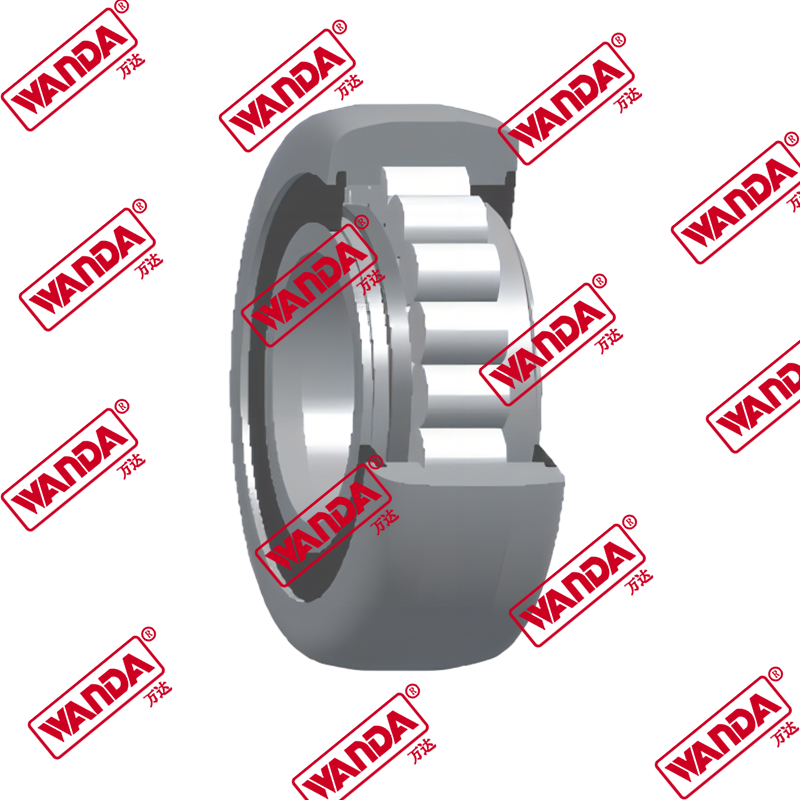

2.1 Minimizing Friction and Mechanical Wear Under High Loads

Designed to carry and evenly distribute heavy forklift loads, slewing bearings significantly reduce friction between rotating components, decreasing wear during continuous high-pressure operation and prolonging the lifespan of critical parts.

2.2 Cutting Maintenance Costs Through Enhanced Reliability

By preventing excessive wear and friction-related damage, these bearings reduce the frequency and cost of repairs. The reliable support system lowers downtime, helping enterprises maintain steady productivity and reducing total cost of ownership.

2.3 Ensuring Consistent Performance in Demanding Conditions

Even in extreme operating environments, slewing bearings preserve forklift stability and mechanical integrity, enabling uninterrupted, efficient operation over long periods, which is crucial for high-intensity logistics and warehousing tasks.

3. Adaptability and Operator Confidence: Slewing Bearings Empower Efficient Workflows

3.1 Superior Adaptability in Challenging Environments

Forklift Slewing Bearings enable equipment to handle varied pressures during turning, lifting, and stacking in tight, crowded, or uneven spaces. Their uniform force distribution counters instability caused by environmental factors, enhancing operational resilience.

3.2 Enhancing Operator Confidence and Safety

With improved stability, forklift operators can perform complex maneuvers with greater confidence, reducing the likelihood of accidents and operational errors, especially when working with heavy or awkward loads in constrained spaces.

3.3 Boosting Productivity Through Stable Operation

Stable forklift performance translates directly into improved work accuracy and efficiency. The slewing bearing system not only lessens operator stress but also supports continuous smooth operation, ultimately enhancing overall warehouse productivity and safety.