1. Tackling Wear Challenges: Forklift Slewing Ring Enhances Durability and Performance

1.1 Wear Issues Plaguing Traditional Slewing Bearing Systems

Forklifts endure immense weight loads and frequent steering, which place heavy stress on slewing bearing systems. Under constant multidirectional pressure and friction, traditional bearings experience surface wear that degrades rotation accuracy and forklift performance. Harsh environments like high temperature, humidity, and dust accelerate this wear, leading to increased maintenance frequency and reduced operational efficiency.

1.2 Consequences of Excessive Wear on Operation

As slewing bearings wear down, forklift steering flexibility diminishes, potentially causing jamming, abnormal noises, and operational interruptions. Severe wear can lead to system failure, forcing forklift downtime and disrupting continuous production workflows—posing significant risks in demanding industrial settings.

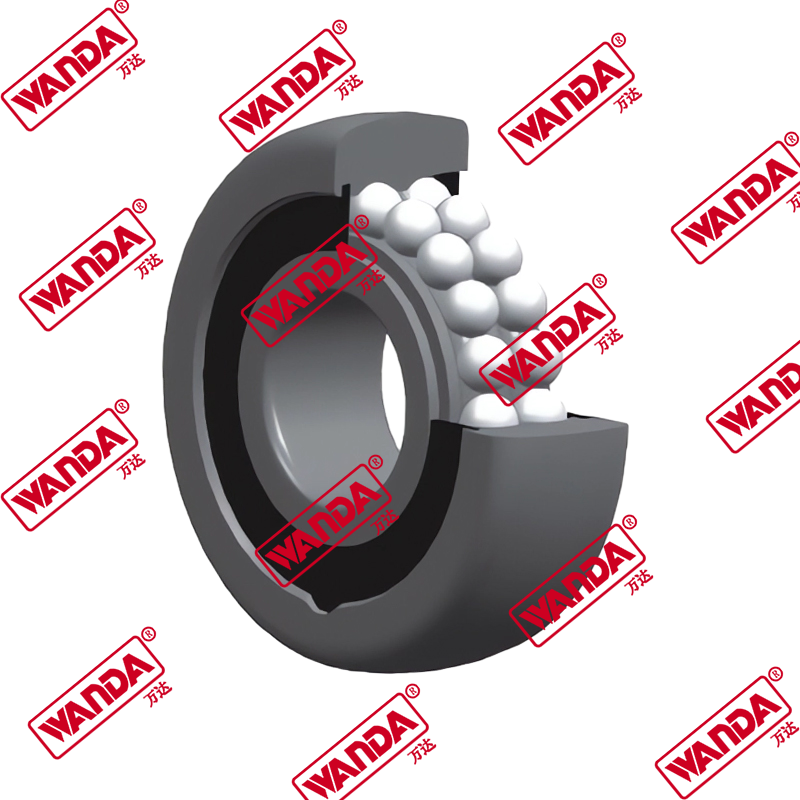

1.3 Innovative Solutions via Forklift Slewing Ring Design

Addressing these problems, the Forklift Slewing Ring integrates precision engineering with high-strength materials to significantly improve wear resistance. This core rotational component optimizes friction and impact endurance, ensuring consistent performance even under heavy loads and frequent turns, reducing wear-related losses and maintaining efficiency in challenging environments.

2. Extending Forklift Lifespan: Reduced Maintenance and Cost Benefits of Advanced Slewing Rings

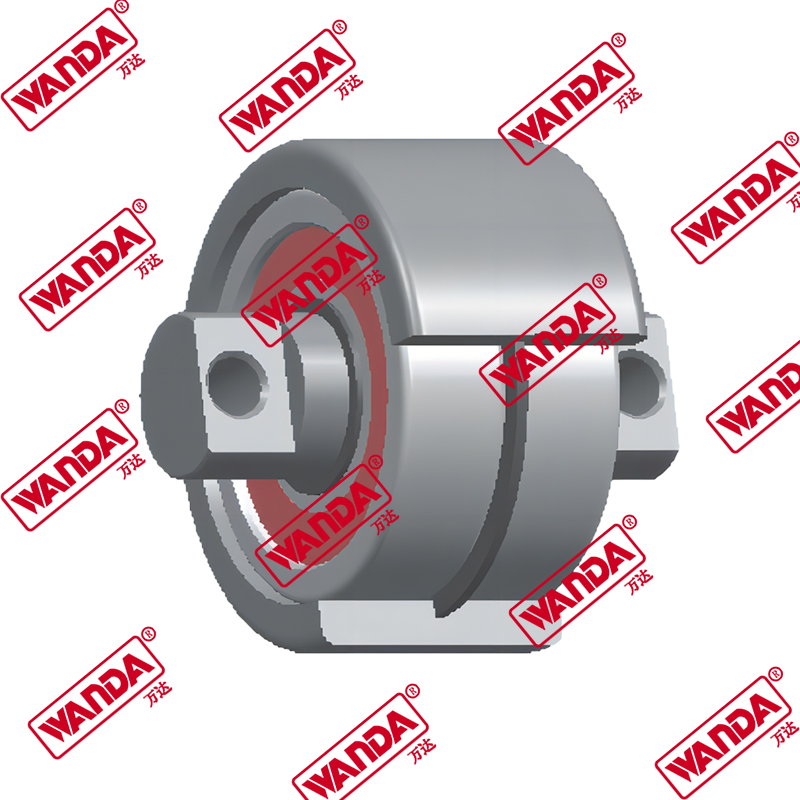

2.1 Enhancing Service Life through Superior Material Selection

The durability and corrosion resistance of the slewing bearing directly impact forklift longevity. Unlike traditional bearings prone to rapid wear and aging, the Forklift Slewing Ring employs advanced, high-strength materials that increase resistance to wear, corrosion, and environmental degradation, thus extending the operational lifespan of key forklift parts.

2.2 Cutting Maintenance Frequency and Associated Costs

By minimizing wear and preventing premature failure, the Forklift Slewing Ring significantly reduces the need for frequent repairs and part replacements. This not only lowers downtime but also alleviates maintenance budgets, which traditionally burden many enterprises, thereby improving overall cost efficiency and operational stability.

2.3 Boosting Enterprise Productivity with Reliable Equipment

Sustained reliability through the Forklift Slewing Ring ensures forklifts operate smoothly for extended periods, facilitating uninterrupted workflow. Reduced maintenance requirements translate to higher equipment availability and productivity, empowering businesses to optimize production schedules and resource allocation effectively.

3. Adaptability and Efficiency: Forklift Slewing Ring Ensures Stable Operation Across Harsh Environments

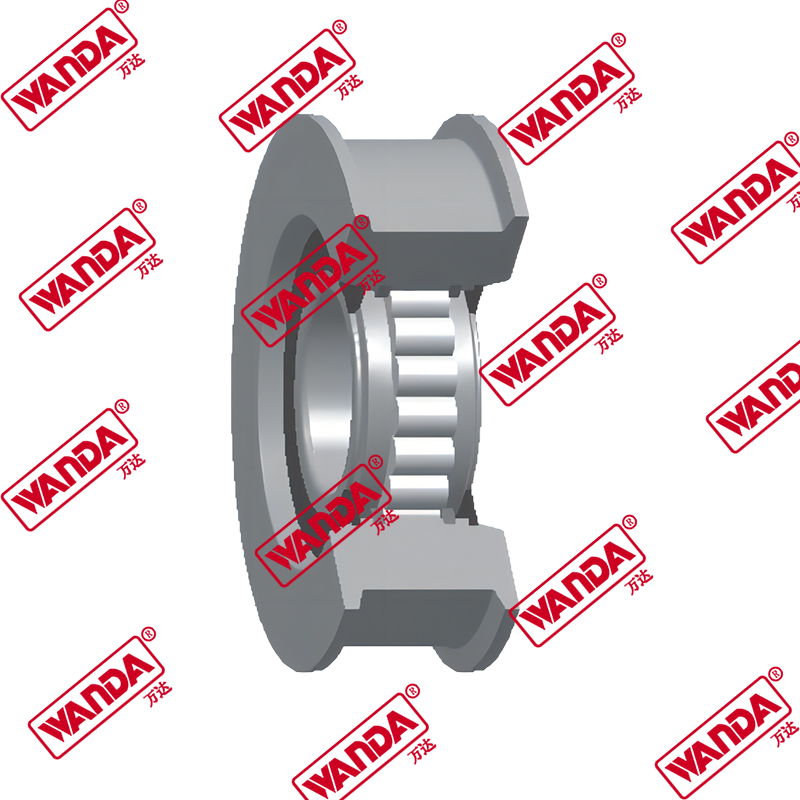

3.1 Designed for Extreme Conditions: Heat, Humidity, and Dust Resistance

Forklifts often operate in diverse and harsh conditions including elevated temperatures, high humidity, and dusty environments where traditional slewing bearings falter. The Forklift Slewing Ring is engineered with corrosion-resistant and heat-tolerant materials, maintaining stable and reliable performance despite environmental challenges.

3.2 Maintaining Operational Stability and Reducing Failure Risks

This advanced slewing bearing design mitigates the adverse effects of environmental factors that commonly cause wear and corrosion. By ensuring stable rotation and load distribution, it minimizes forklift failures linked to harsh working conditions, thereby protecting equipment integrity and workflow continuity.

3.3 Improving Work Efficiency by Minimizing Downtime

Reduced failure rates associated with the Forklift Slewing Ring enhance overall forklift availability and operational efficiency. This enables enterprises to meet production targets consistently while providing a safer, more stable working environment that supports both operators and management in high-demand logistics and warehousing scenarios.