1.Forklift Mast Guide Bearings Drive a New Era of Efficiency in Material Handling

1.1 Friction: The Hidden Barrier to Optimal Forklift Performance

In the daily operation of forklifts, especially in logistics and warehousing environments, friction between the lift bracket and mast guide rail creates continuous resistance. This friction leads to energy loss, higher fuel or battery consumption, and a strain on the power system. When left unaddressed, it not only undermines performance but also accelerates equipment degradation.

1.2 High-Frequency Operations Amplify the Consequences of Friction

Forklifts often perform intensive, repetitive lifting tasks. Excessive friction in such high-frequency applications multiplies wear on mechanical components and demands more power per cycle. This not only increases the risk of malfunction but also severely impacts turnaround times and operational consistency.

1.3 Demand for Smart Component Design in Power Systems

The industry is shifting toward smarter, more energy-conscious machinery. A key focus lies in upgrading core mechanical components, such as bearings, that directly affect system resistance and energy consumption. This is where Forklift Mast Guide Bearings provide a transformative solution—optimizing load handling with minimal energy waste.

2.Forklift Mast Guide Bearings Deliver Tangible Performance Improvements

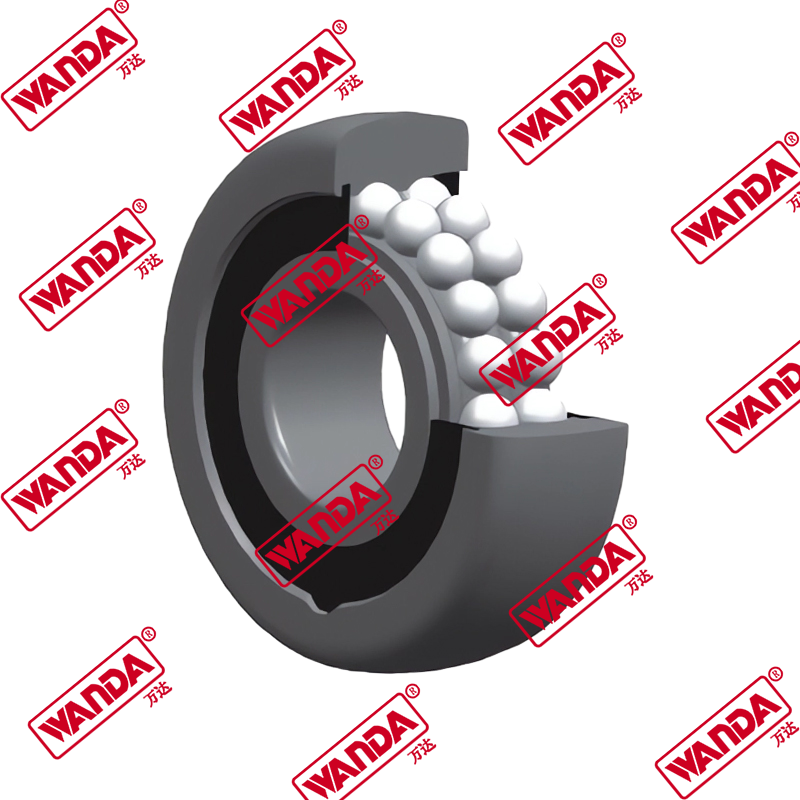

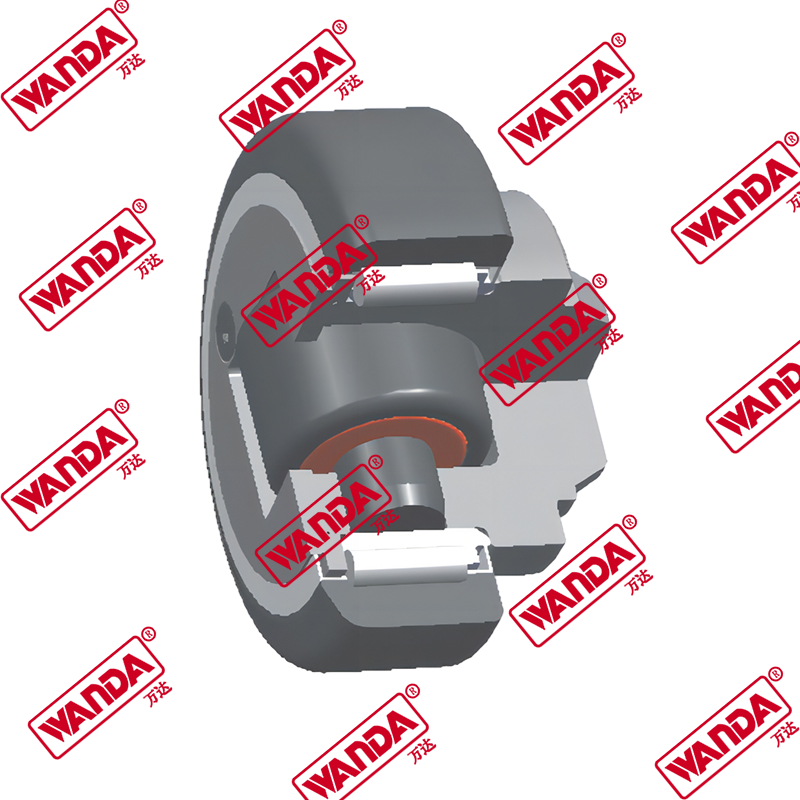

2.1 Precision Engineering Reduces Friction and Energy Waste

The Forklift Mast Guide Bearing is designed with high-strength materials and exact tolerance engineering to ensure minimal resistance during lift operations. By significantly decreasing friction between moving parts, it allows for smoother, faster, and more responsive lifting actions—without straining the powertrain.

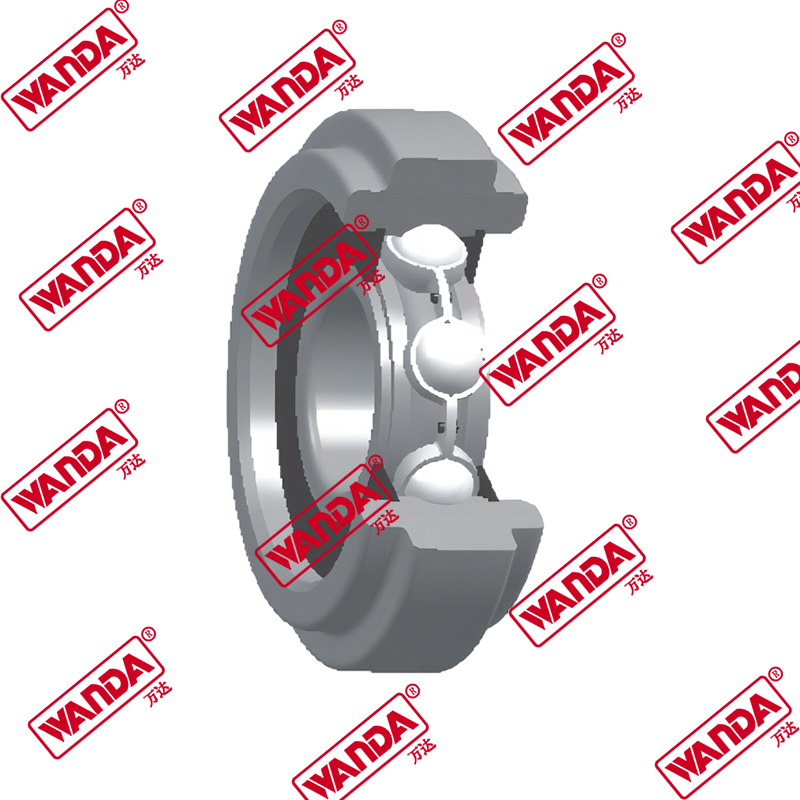

2.2 Improved Power Transmission Enhances Efficiency

A forklift equipped with high-quality mast guide bearings can achieve better energy conversion rates during lifting. Reduced friction means less energy is required to move the same load, resulting in higher operational efficiency and extended battery runtime or fuel economy, depending on the power source.

2.3 Stability in Operation Leads to Greater Reliability

Consistent performance under load is critical for operational safety and productivity. The smooth movement enabled by advanced guide bearings eliminates jerky or hesitant lift cycles. This ensures better cargo handling, reduced operator fatigue, and greater trust in the equipment’s performance, especially in precision-demanding environments like racking or tight-space logistics.

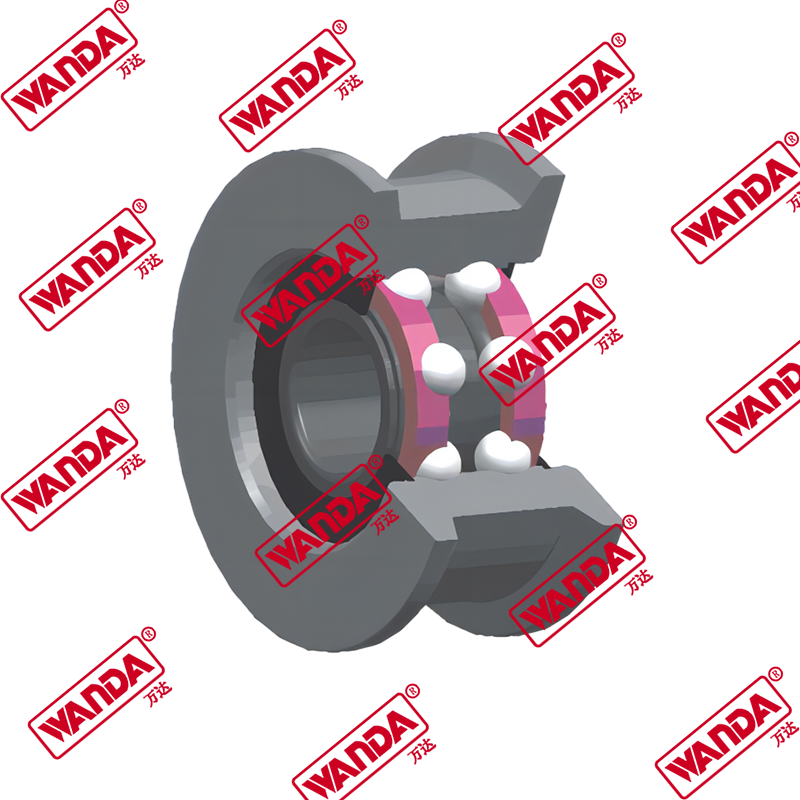

3.Lower Costs and Safer Operation Through Component Innovation

3.1 Reduced Wear Extends Equipment and Component Life

By minimizing direct mechanical contact and stress between the lifting bracket and the mast channel, mast guide bearings substantially reduce long-term wear. This not only extends the lifespan of the bearings themselves but also protects adjacent components—like chains, rails, and drive mechanisms—from early failure.

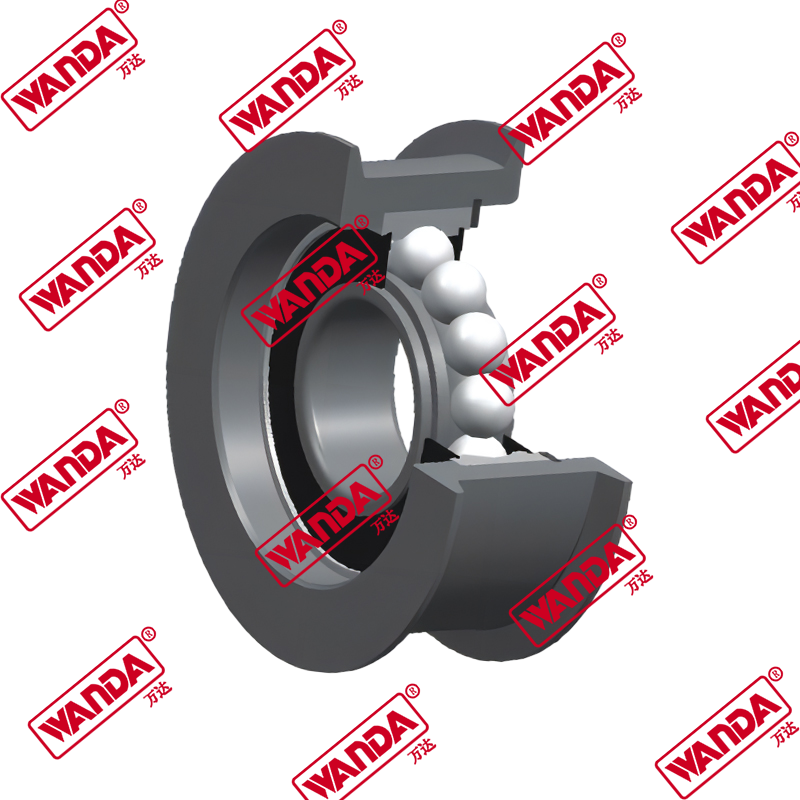

3.2 Lower Maintenance Requirements Save Operational Costs

With less wear and smoother motion, forklifts require less frequent maintenance, fewer part replacements, and experience fewer unplanned downtimes. These factors contribute to lower lifetime operating costs, improved fleet availability, and greater ROI on capital equipment investments.

3.3 Smoother Lifting Enhances Operator Safety and Control

A critical but often overlooked benefit of reduced friction is improved handling safety. When lift movements are smooth and responsive, operators experience greater control over loads, reducing the risk of drops, load shifts, or system lockups. This minimizes safety incidents and creates a more secure workplace for both operators and surrounding personnel.