1: Forklift Mast Roller Bearings: A Critical Solution to Lifting System Jamming in Modern Warehousing

1.1: Jamming Threatens Operational Continuity in High-Intensity Environments

Forklift lifting systems frequently encounter jamming issues under heavy loads and high-frequency operation, leading to reduced operational efficiency and even sudden halts. These disruptions can delay the flow of goods, disrupt warehouse logistics, and escalate maintenance requirements.

1.2: The Role of Bearings in Smooth Vertical Movement

As core components of the mast lifting mechanism, roller bearings directly affect the system’s smoothness and reliability. Inferior bearings often lack the precision and durability required for continuous industrial use, making forklifts prone to jamming during upward or downward travel.

1.3: Lifting Arm Vulnerability Increases Under Load Without Bearing Support

The vertical mast endures significant multidirectional stress. Without dependable roller bearings, this stress results in resistance, misalignment, and mechanical instability—factors that directly impact cargo handling speed and safety.

2: High-Quality Forklift Mast Roller Bearings Ensure Lifting Precision and Reduce Mechanical Friction

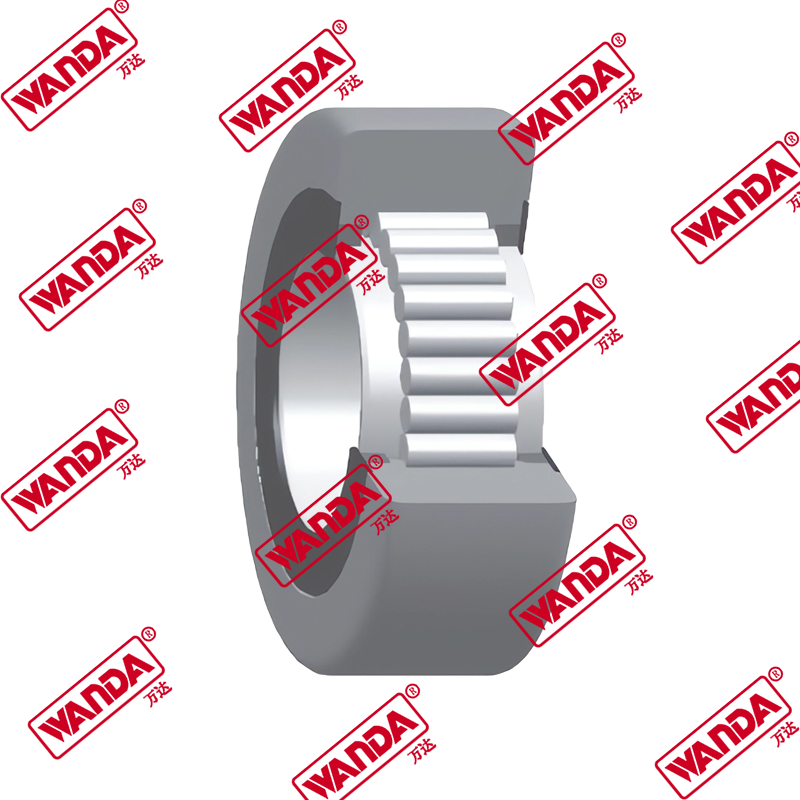

2.1: Precision Engineering Enables Seamless Component Integration

Advanced manufacturing techniques ensure each bearing is dimensionally accurate and geometrically consistent. This precision eliminates misalignment between moving parts, allowing the lifting mast to glide smoothly along guide rails even under intense workload conditions.

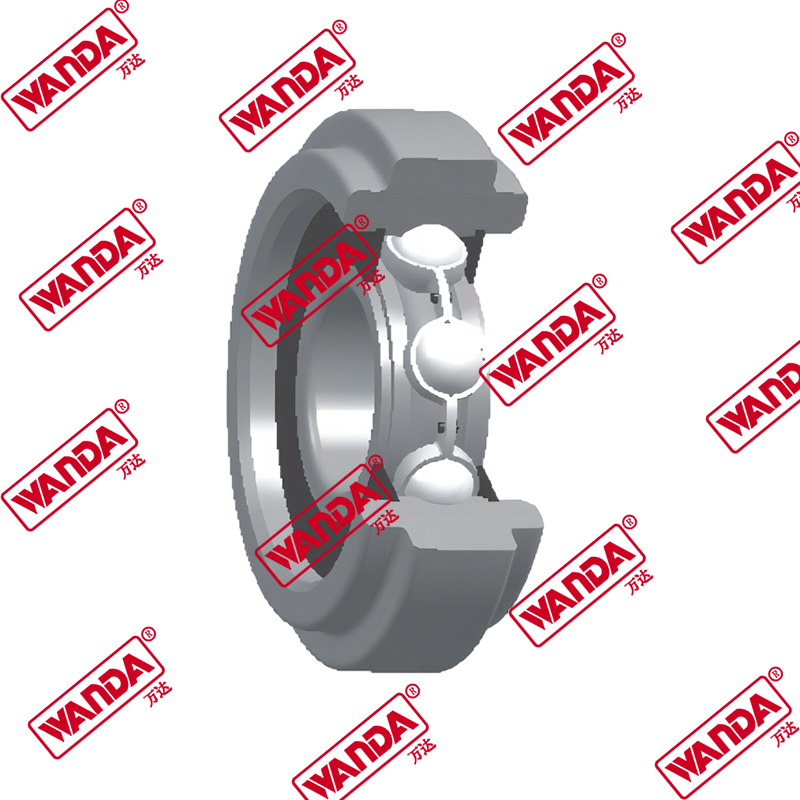

2.2: Friction Reduction Minimizes Energy Waste and Component Fatigue

High-performance bearings are designed with optimized surface finish, lubrication channels, and tight tolerance controls. These attributes significantly reduce frictional drag, ensuring energy-efficient operation and prolonging component life by limiting wear and tear.

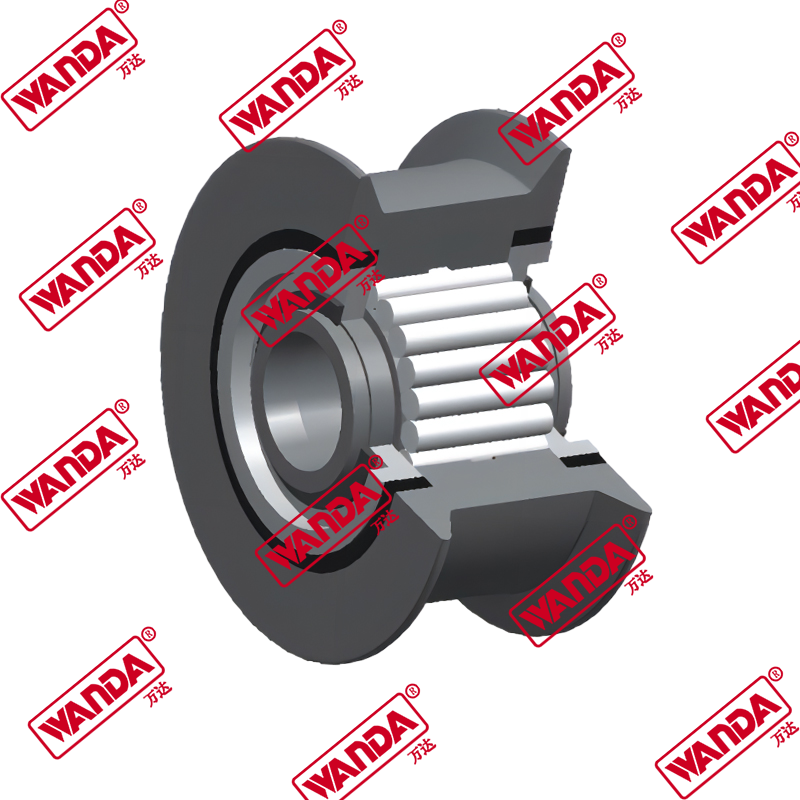

2.3: Durable Bearings Maintain Performance Across Variable Loads

Top-grade materials and heat-treated surfaces empower bearings to withstand a wide range of load intensities and temperature variations. Whether handling light pallets or full-capacity containers, the forklift maintains consistent lifting performance.

3: Boosting Operational Efficiency and Reducing Downtime with Superior Mast Roller Bearings

3.1: Enhanced Stability Enables Continuous, High-Cycle Operations

Uniform load distribution and robust bearing design contribute to a stable mast system that resists vibration, deformation, and positional drift. The result is higher lifting accuracy and uninterrupted performance during peak operational hours.

3.2: Fewer Breakdowns Lead to Lower Maintenance and Greater Cost Efficiency

By minimizing jamming and internal wear, premium roller bearings extend the maintenance intervals of forklifts. This reduces the need for emergency repairs, replacement costs, and associated labor, directly benefiting a company’s bottom line.

3.3: Reliable Mast Systems Empower Streamlined Warehouse Logistics

With dependable lifting systems in place, warehouse operations can proceed without unexpected delays. Faster, smoother handling cycles translate into improved throughput, enabling logistics teams to meet demanding schedules and volume targets with confidence.