1: Crossed Roller Slewing Ring External Gear Enhances Load Capacity Through Uniform Load Distribution

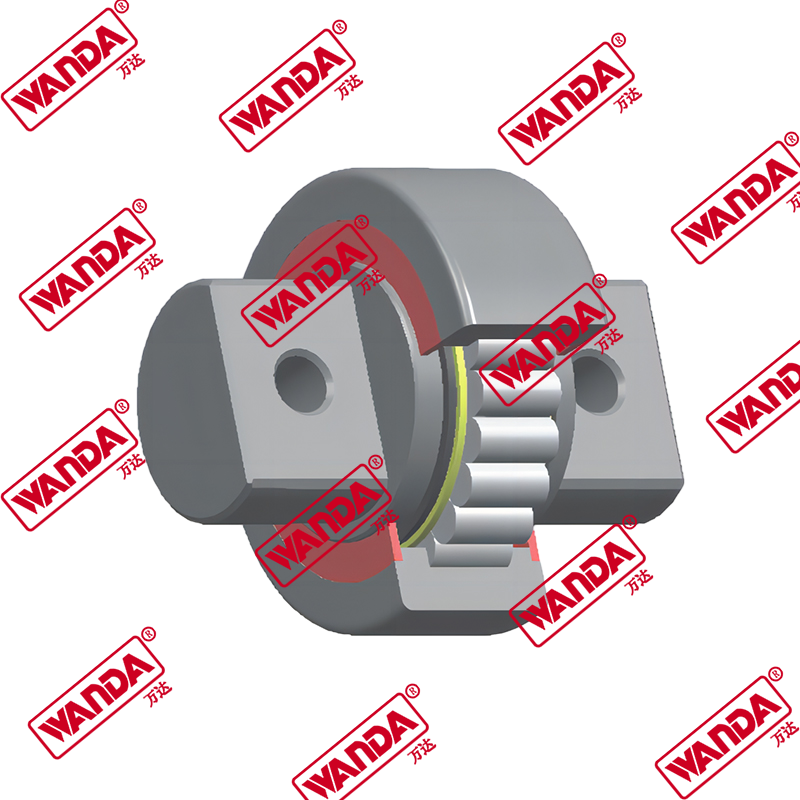

1.1: Addressing Load Concentration in Traditional Designs

In conventional mechanical systems, uneven load distribution often leads to localized pressure points, accelerating wear and compromising equipment longevity. The Crossed Roller Slewing Ring External Gear counters this by distributing loads across multiple contact points, eliminating hotspots that degrade performance over time.

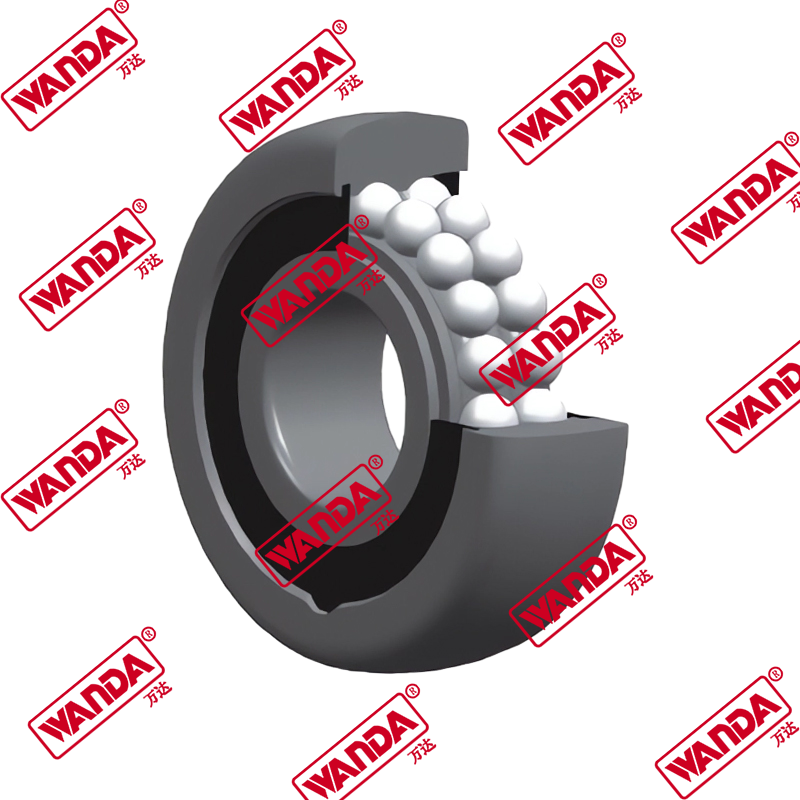

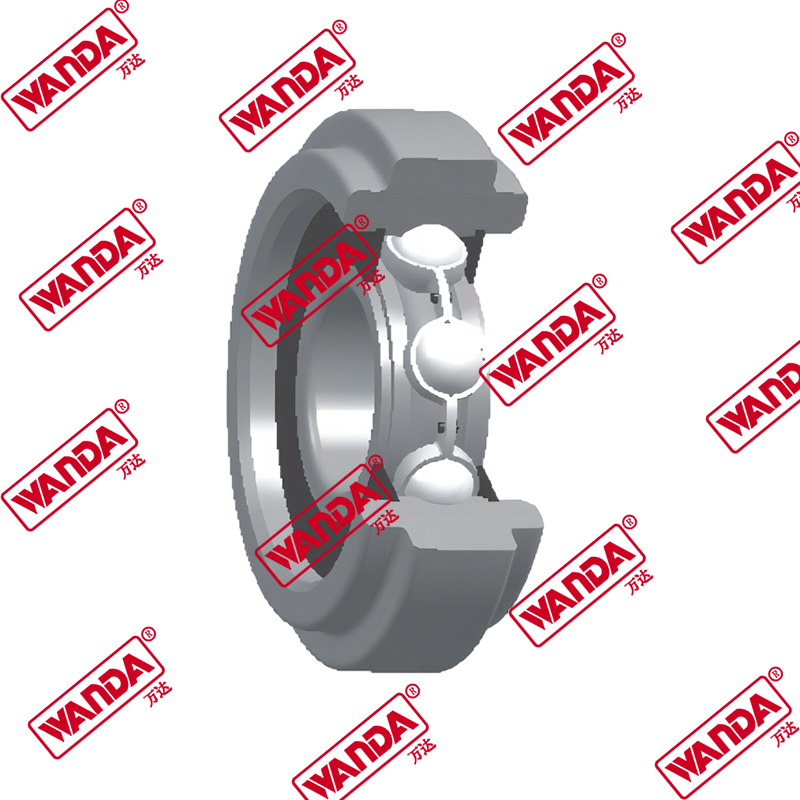

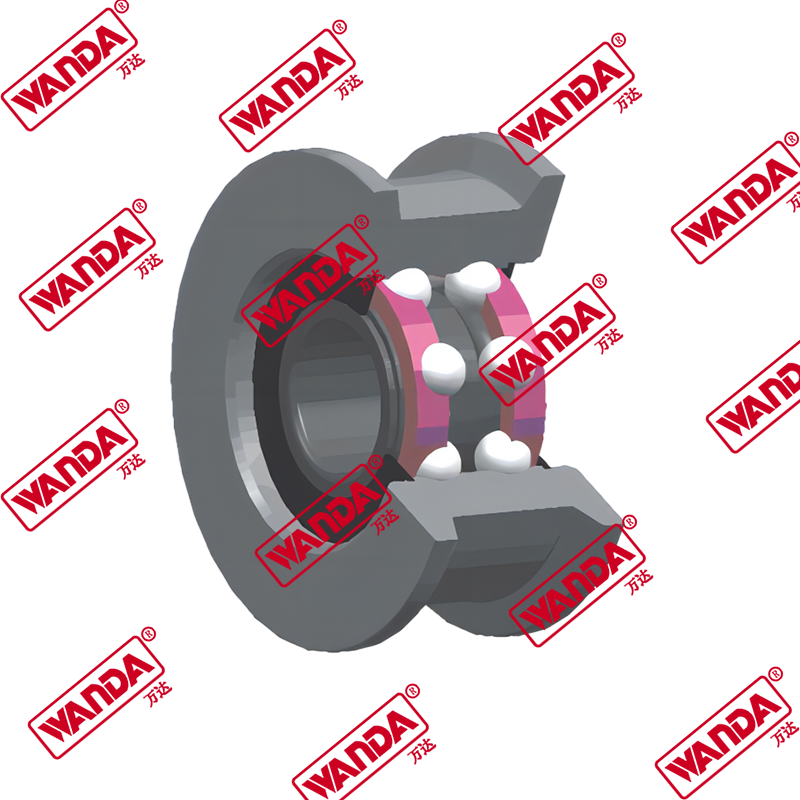

1.2: Crossed Roller Design Supports Consistent High-Load Operation

The heart of the innovation lies in its cross-arranged cylindrical rollers that ensure uniform stress distribution. This architecture allows each roller to share the load equally, reducing the likelihood of localized deformation and improving structural integrity under stress.

1.3: Precision Engineering Ensures Surface Contact Accuracy

Manufactured to tight tolerances, the contact surfaces between rollers and raceways are perfectly aligned to maximize load-sharing efficiency. This precision assembly prevents premature wear and ensures that the equipment can consistently operate under extreme conditions with minimal performance degradation.

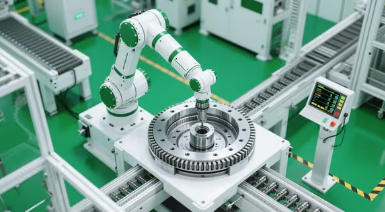

2: Stability and Performance Optimized for High-Load Industrial Applications

2.1: Designed to Withstand Extreme Load Without Structural Deformation

The Crossed Roller Slewing Ring External Gear is engineered to handle the rigors of high-load environments such as cranes, wind turbines, and industrial robotics. Its advanced geometry ensures that forces are distributed evenly, avoiding component stress that can lead to cracks or fractures.

2.2: Enhanced Vibration Resistance for Precise Operation

By minimizing load imbalance, the slewing ring reduces vibrational energy transfer throughout the system. This leads to smoother motion, more accurate control in automated machinery, and increased safety margins—particularly vital in high-speed, precision-driven industries.

2.3: Stable Operation Reduces Downtime and Risk of Malfunction

In applications where equipment failure can halt entire operations, the enhanced stability of this gear solution ensures continuous uptime. Its ability to perform under high stress without performance drop-off or failure represents a major leap forward for heavy-duty industries.

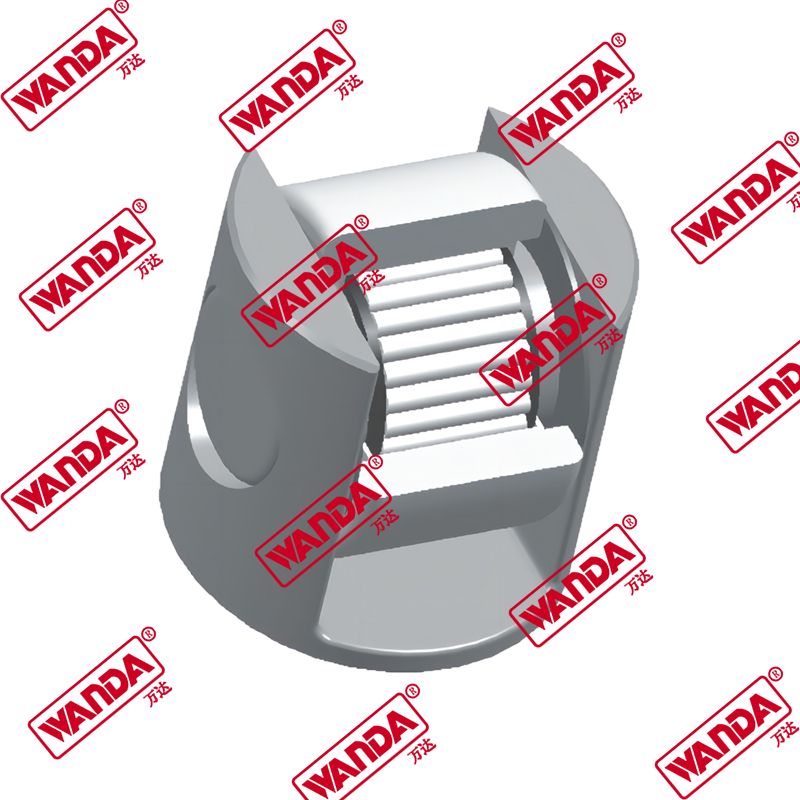

3: Uniform Load Transfer Extends Equipment Life and Reduces Maintenance Costs

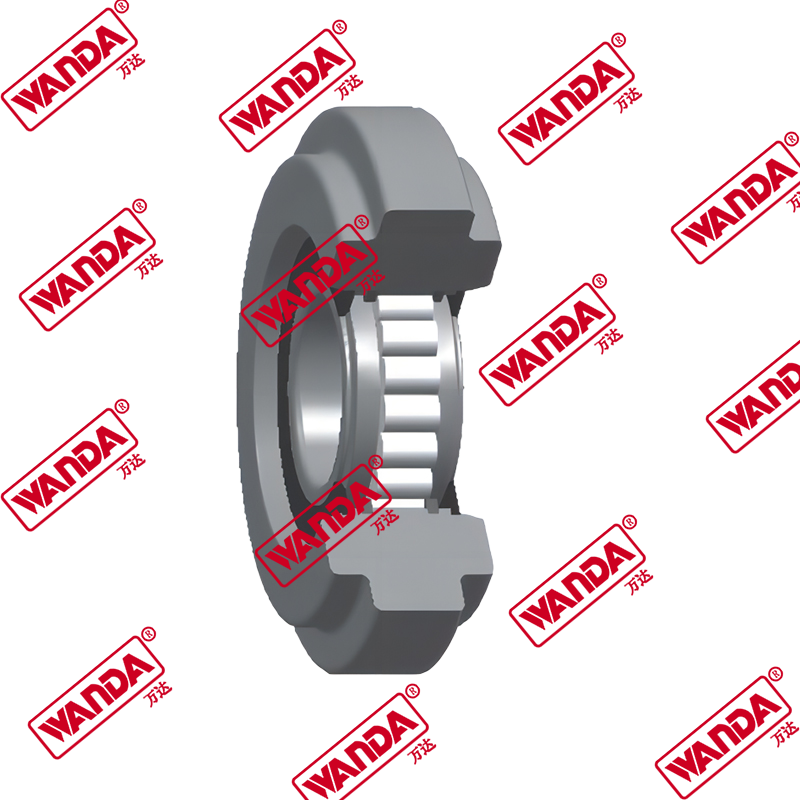

3.1: Wear Minimization Through Even Force Dispersion

Traditional gear systems suffer from rapid wear at pressure points. The Crossed Roller Slewing Ring External Gear’s ability to equalize force loads reduces mechanical abrasion, maintaining surface integrity and reducing the frequency of part replacements.

3.2: Lower Maintenance Frequency Translates to Long-Term Cost Savings

The improved durability and wear resistance of the system significantly reduce the need for scheduled maintenance. Equipment downtime is minimized, while service intervals are extended, resulting in substantial cost savings over the life of the machinery.

3.3: Long Lifespan Supports Sustainable Industrial Performance

By enhancing both mechanical reliability and operational efficiency, this slewing ring design helps industries achieve sustainability goals. Less frequent part replacement and lower maintenance needs contribute to environmentally responsible and economically viable production systems.