1. Accurate rotation control: improve work efficiency

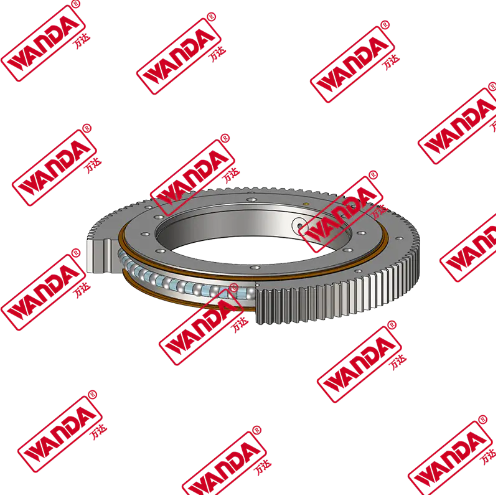

Four-point contact slewing ring with external gear combines external gear design to provide a highly accurate rotation control system for equipment. With the continuous improvement of mechanical equipment's requirements for rotation accuracy, traditional slewing bearings are gradually unable to meet the requirements of modern heavy machinery for accuracy and efficiency. The Four-point contact slewing ring with external gear, through its precise design, not only improves the accuracy of rotation, but also ensures that every degree of rotation of the equipment during operation can be accurately controlled.

The core advantage of this design lies in the use of external gears. Compared with traditional slewing bearings, Four-point contact slewing ring with external gear can effectively reduce the friction and clearance between gears during the transmission process, thereby improving the accuracy of transmission. The external gear design makes the transmission system of the slewing bearing more stable, avoids the common phenomenon of poor gear meshing in traditional slewing bearings, and further improves the rotation accuracy.

This precise rotation control can greatly improve the working efficiency of mechanical equipment. Especially in equipment that requires frequent angle adjustment and direction changes, the Four-point contact slewing ring with external gear can ensure that each rotation is highly consistent, thereby reducing misoperation caused by inaccurate rotation. This reduction in error not only improves work efficiency, but also effectively reduces the risk of equipment damage caused by improper operation by operators.

2. Avoid the risks of inaccurate rotation

In the working environment of heavy machinery, unstable or inaccurate rotation may cause a series of serious problems. The equipment may fail due to rotation errors, or even structural damage, resulting in high repair costs and downtime losses. The Four-point contact slewing ring with external gear can effectively avoid this risk with its excellent precision.

Accurate rotation control is the basis for ensuring efficient and stable operation of equipment. The Four-point contact slewing ring with external gear ensures that each rotation is carried out within the predetermined range by reducing friction and clearance between gears, avoiding misoperation of the equipment due to inaccurate rotation. This high-precision control not only reduces human errors, but also enhances the overall stability of the equipment.

Especially in some high-load and high-intensity working environments, the precise rotation control brought by the Four-point contact slewing ring with external gear can significantly improve the reliability of the equipment. The operating efficiency of the equipment has been greatly improved, the failure rate has been greatly reduced, and the operator can focus more on other key operations without worrying about equipment failures caused by rotation problems.

3. Advantages of Four-point contact slewing ring with external gear: Improve operating experience

The design of Four-point contact slewing ring with external gear enables it to play a vital role in modern machinery. Compared with traditional slewing bearing systems, Four-point contact slewing ring with external gear not only has higher transmission accuracy, but also its design focuses more on durability and reliability. By reducing the friction and poor contact of the gears, Four-point contact slewing ring with external gear ensures that the equipment can still maintain stable operation under high-load working conditions.

The rotation accuracy of the equipment may directly determine the production efficiency in some machinery. For example, if the equipment causes unnecessary errors due to inaccurate rotation, it may require multiple adjustments, which takes a lot of time. Four-point contact slewing ring with external gear not only improves the smoothness of operation through its precise rotation control system, but also reduces unnecessary adjustments and rework, greatly improving the overall operating efficiency of the equipment.

4. Improve work efficiency and reduce equipment loss

Precise rotation control not only improves work efficiency, but also effectively reduces the loss caused by unstable equipment operation. In the long-term use of mechanical equipment, if the rotation is unstable, it will cause the wear of the internal parts of the equipment to increase, thereby shortening its service life. Four-point contact slewing ring with external gear reduces this unstable factor and extends the service life of the equipment with its precise rotation control.

Through the optimized design, Four-point contact slewing ring with external gear effectively reduces the load fluctuation of the equipment under high-intensity operation and reduces the risk of damage caused by operating errors or equipment instability. This not only saves the cost of maintenance and replacement of parts, but also reduces equipment downtime, saving a lot of costs for the company.