1. Impact and challenges of vibration on equipment

During the operation of high-load equipment, vibration is often an unavoidable external interference factor, especially when long-term continuous operation is required. The impact of vibration is particularly significant. During the operation of the equipment, any form of vibration will have an adverse effect on the system. These vibrations may not only destroy the accuracy of the equipment, but also cause fatigue damage to mechanical parts. Especially under conditions of high-speed rotation or heavy-load operation, vibrations tend to accelerate the wear of parts, thereby affecting the stability and service life of the equipment.

In addition, vibrations may also cause resonance inside the equipment, which will increase the intensity of vibration and put greater pressure on the equipment. Vibration not only has a negative impact on the mechanical part of the equipment, but may also cause instability in the electrical system, hydraulic system or other key systems of the equipment, increase the risk of equipment failure, and then lead to production stagnation, and increase maintenance and downtime costs. Therefore, how to effectively reduce the impact of vibration on the equipment has become the key to improving equipment performance.

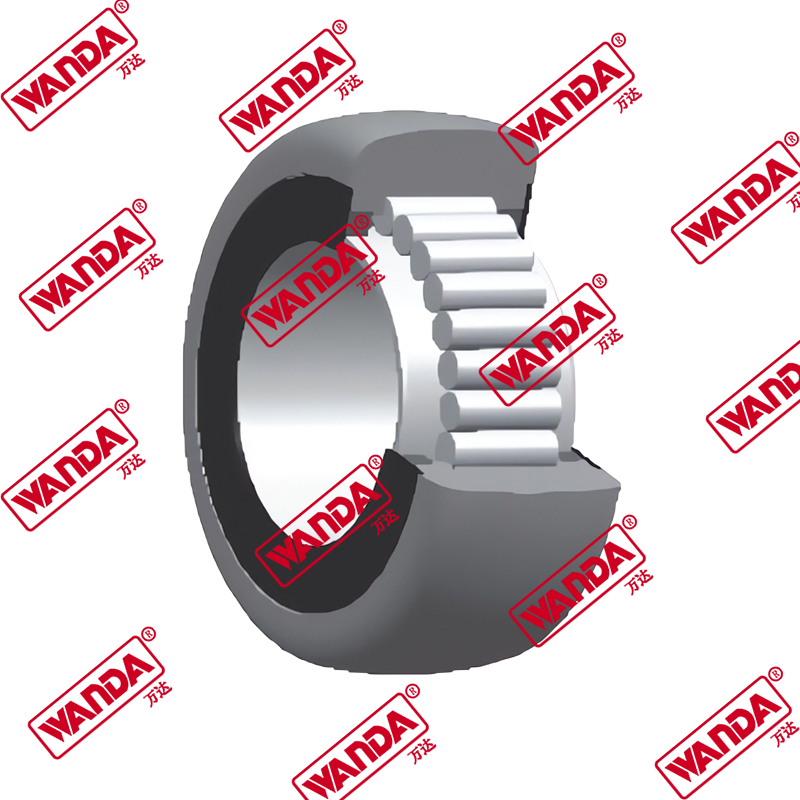

2. Design advantages of Four-Point Contact Slewing Ring

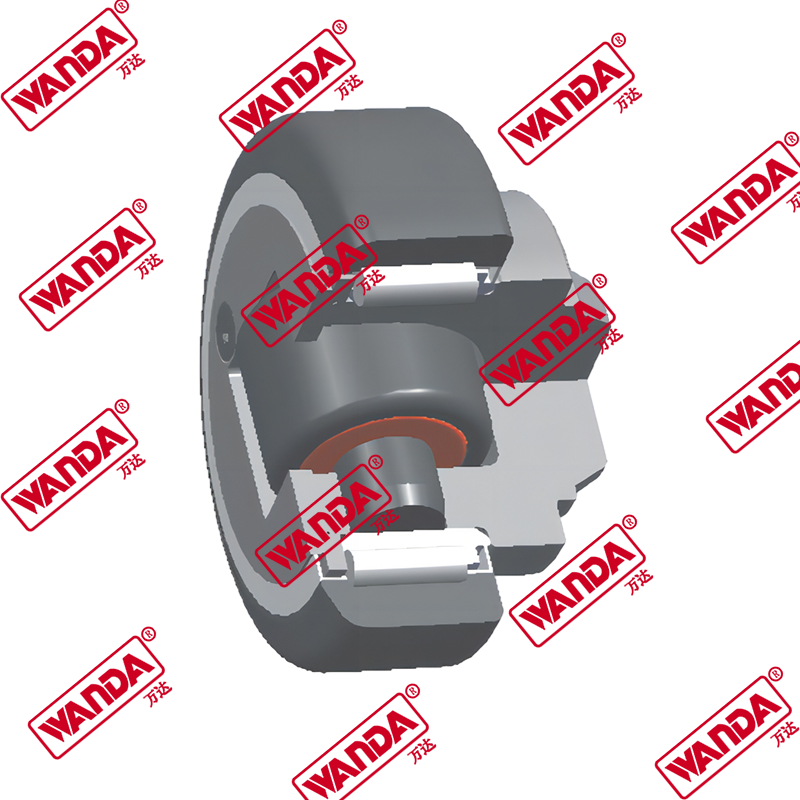

Four-Point Contact Slewing Ring effectively reduces the impact of vibration on the equipment through its unique four-point contact design. In traditional rotating support devices, two-point or three-point contact is usually used. This design easily leads to uneven load distribution, resulting in greater vibration during load transfer. The Four-Point Contact Slewing Ring evenly distributes the load through four contact points, avoiding vibration caused by uneven load and effectively reducing the impact of vibration on equipment performance.

This four-point contact design can maintain uniform load transfer during the operation of the equipment, avoiding vibration and wear caused by excessive local pressure. This optimized load distribution not only reduces fatigue and damage to equipment components, but also improves the accuracy and stability of the equipment, especially under high load and long-term operation, it can significantly reduce the negative impact of vibration.

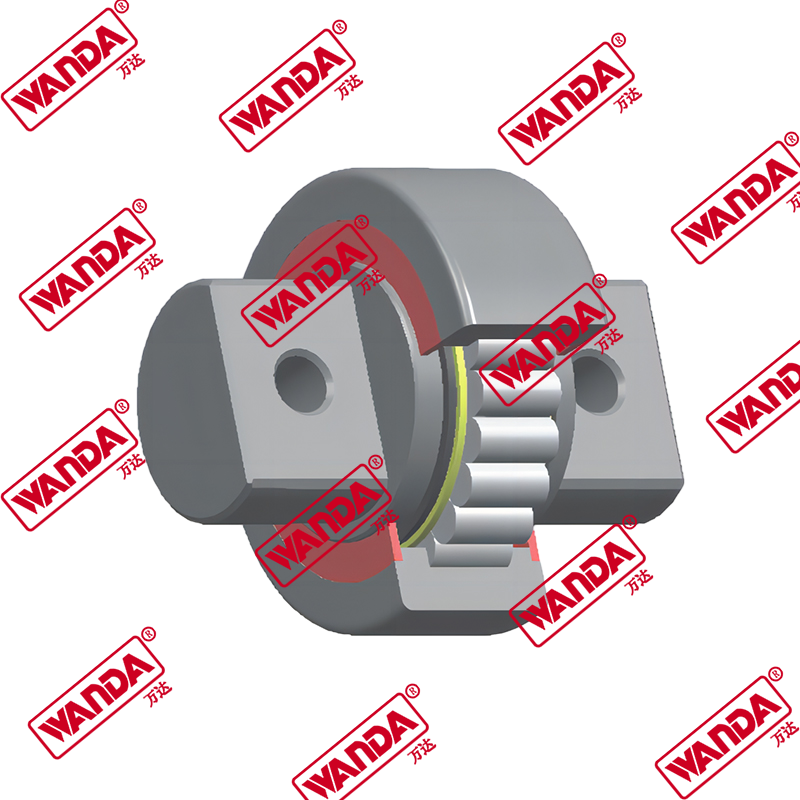

3. Dispersion and absorption of vibration energy

Another important advantage of the Four-Point Contact Slewing Ring is that it can effectively disperse and absorb vibration energy. When operating at high load, the equipment will be subject to shock and vibration from the external environment. If these vibrations are not absorbed and dispersed in time, they may propagate inside the equipment, resulting in a larger vibration amplitude. The Four-Point Contact Slewing Ring can effectively disperse the vibration energy to four contact points through a carefully designed contact point structure, and absorb part of the vibration energy through the elastic properties of the material to prevent the vibration from continuing to amplify inside the equipment.

This design ensures the stability of the equipment in a vibrating environment. Even under extreme load conditions, the vibration can be controlled and absorbed in time, thereby avoiding the transmission and diffusion of vibration and reducing the negative impact on the equipment system. Through this efficient vibration absorption mechanism, the Four-Point Contact Slewing Ring can still maintain the smooth operation of the system under high load and high vibration conditions, greatly reducing the risk of equipment failure caused by vibration.

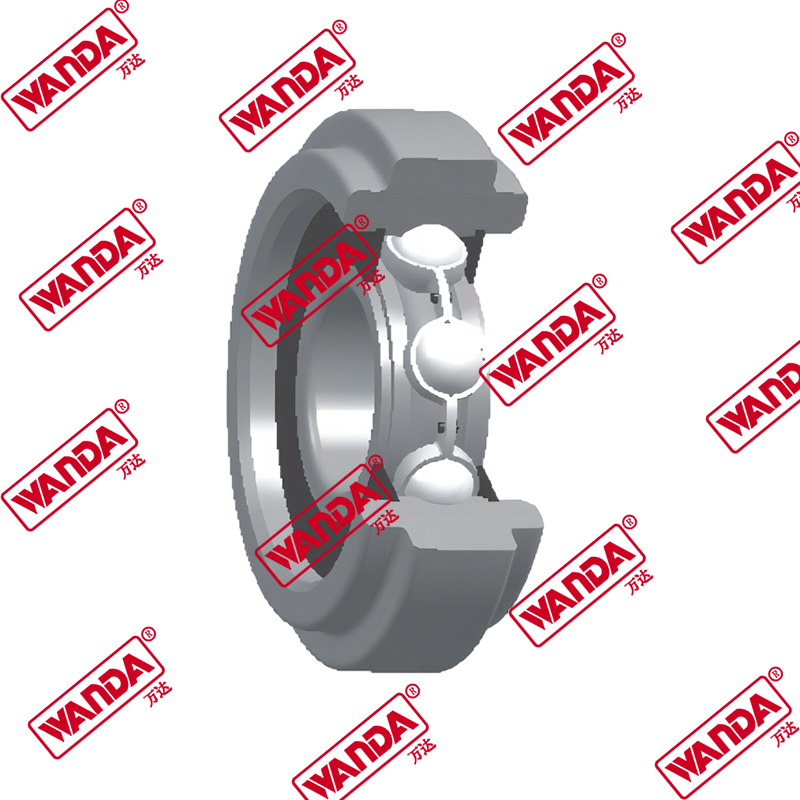

4. Improve the accuracy and stability of the equipment

Vibration will not only affect the stability of the equipment, but also may damage the operating accuracy of the equipment. Especially in equipment that requires highly precise operation, vibration may cause displacement and error of equipment components, thereby affecting the overall working effect. The Four-Point Contact Slewing Ring can effectively reduce the impact of vibration on equipment accuracy and maintain the precise operating performance of the equipment through its precise load distribution and vibration absorption capabilities.

During high load and long-term operation of the equipment, vibration is often one of the most difficult factors to control. Through the design of the Four-Point Contact Slewing Ring, vibration is effectively absorbed and reduced, ensuring that the equipment can continue to maintain high accuracy and stability during operation. This high stability not only improves the working efficiency of the equipment, but also reduces the errors and deviations caused by vibration, ensuring the reliability of the equipment in various environments.

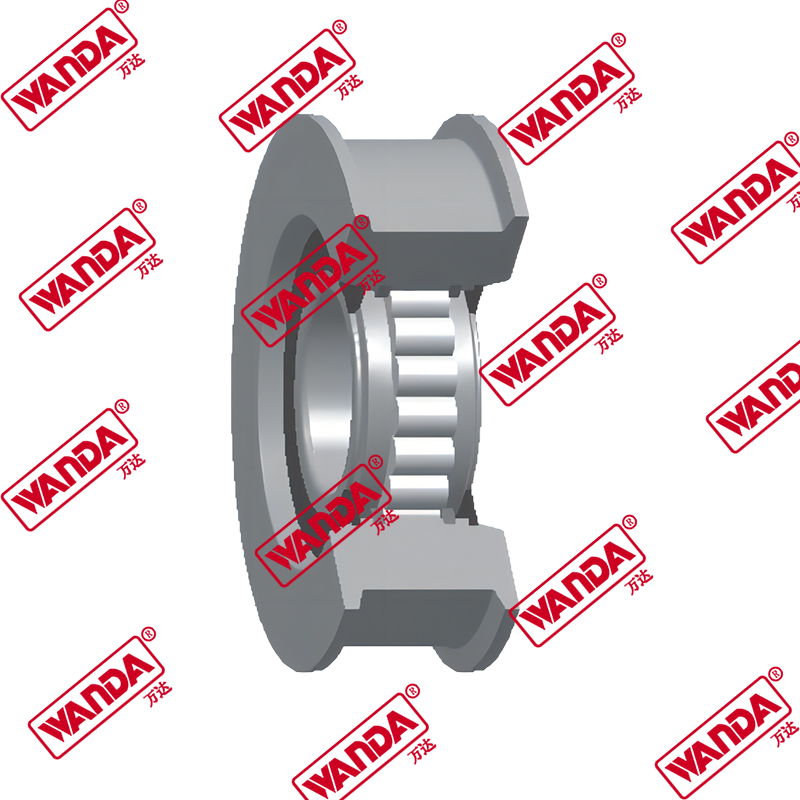

5. Extend the service life of the equipment and reduce the risk of failure

By reducing the impact of vibration and shock on the equipment, the Four-Point Contact Slewing Ring can significantly extend the service life of the equipment. Vibration and shock are one of the main factors that cause equipment wear and failure, especially in high-load and high-intensity working environments, the wear effect of vibration on the equipment is more obvious. Through optimized design, the Four-Point Contact Slewing Ring can effectively reduce the negative impact of vibration and shock on the equipment, thereby reducing equipment wear and extending the service life of the equipment.

In addition, the Four-Point Contact Slewing Ring can also reduce the probability of equipment failure by improving the stability and shock resistance of the equipment. Failure caused by vibration is one of the common reasons for equipment downtime. By effectively reducing the impact of vibration on the equipment, the frequency of equipment downtime can be significantly reduced, the repair and maintenance costs can be reduced, and the production efficiency and economic benefits of the equipment can be improved.