Selecting the right roller wheel chain is critical for ensuring the longevity, efficiency, and safety of countless mechanical systems, from conveyor belts to industrial machinery. A high-quality chain reduces downtime, maintenance costs, and operational risks. However, navigating the specifications and features can be daunting. This guide delves into the essential characteristics that define a superior roller wheel chain, empowering you to make an informed purchasing decision. We'll explore material composition, load capacity, wear resistance, and other pivotal factors that directly impact performance in demanding applications. By understanding these key features, you can optimize your equipment's reliability and productivity.

Understanding Roller Wheel Chain Construction and Material

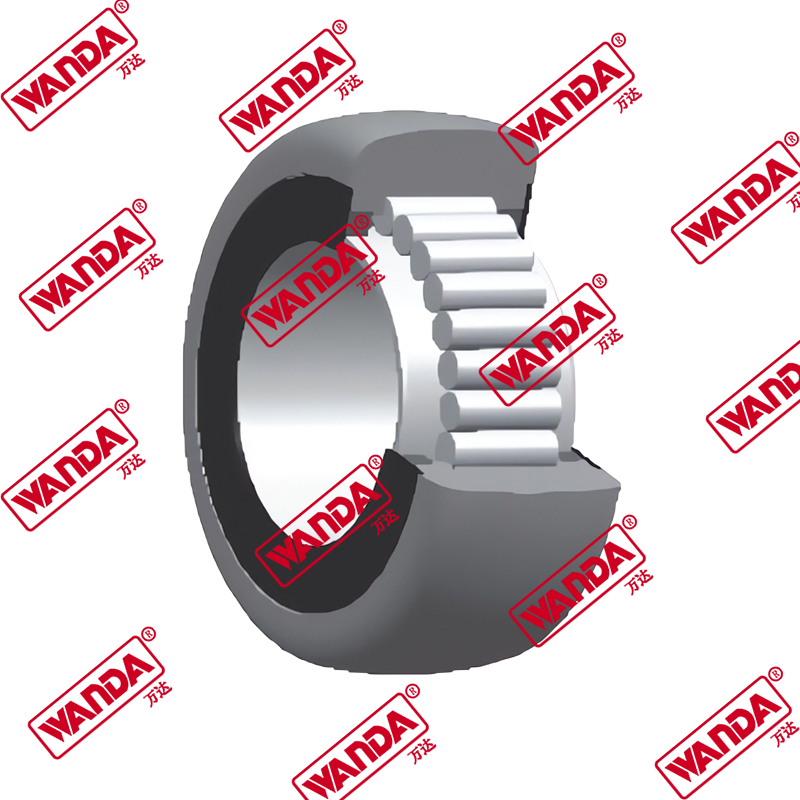

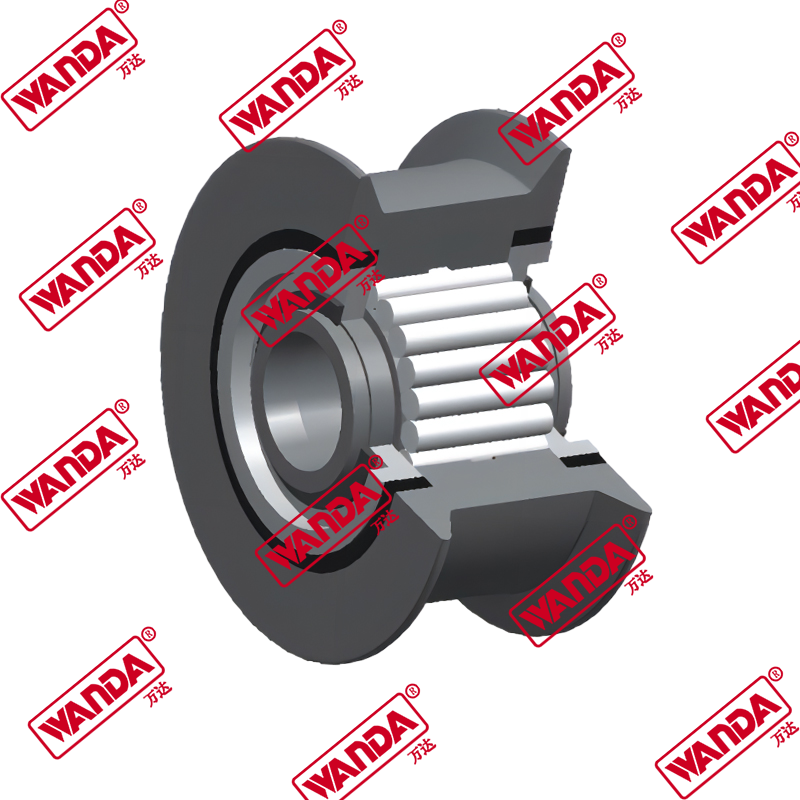

The foundational quality of any roller wheel chain is determined by its construction and the materials used. A chain is only as strong as its weakest link, making material science paramount. High-grade steel alloys, often medium carbon steel or alloy steel, are standard for their excellent tensile strength and durability. The manufacturing process, particularly heat treatment, plays a crucial role. Through-hardening or case hardening processes like carburizing enhance the surface hardness of the pins, bushings, and rollers while maintaining a tough, shock-absorbent core. This combination resists deformation under heavy loads and sudden impacts. Furthermore, attention to precision in the machining of components ensures smooth articulation and even load distribution, which minimizes internal friction and premature wear. The choice of material and construction method directly influences the chain's performance in specific environments, such as those with high moisture, temperature extremes, or exposure to corrosive substances. Therefore, understanding the nuances of roller chain material grades and their treatments is the first step toward selecting a chain that won't fail under pressure.

- Material Grades: Medium carbon steel (e.g., AISI 1030/1040) offers a good balance of strength and cost. Alloy steels (e.g., AISI 3140, 4340) provide higher tensile strength and better fatigue resistance for heavy-duty applications.

- Heat Treatment: Case hardening (carburizing) creates a hard, wear-resistant surface on rollers and pins with a ductile interior. Through-hardening is used for components requiring uniform hardness throughout.

- Precision Manufacturing: Tolerances on pitch (the distance between pin centers) and component dimensions are critical. Tighter tolerances result in smoother operation, less vibration, and reduced sprocket wear.

- Plating & Coatings: Zinc plating, nickel plating, or black oxide finishes can provide a base level of corrosion resistance for standard environments.

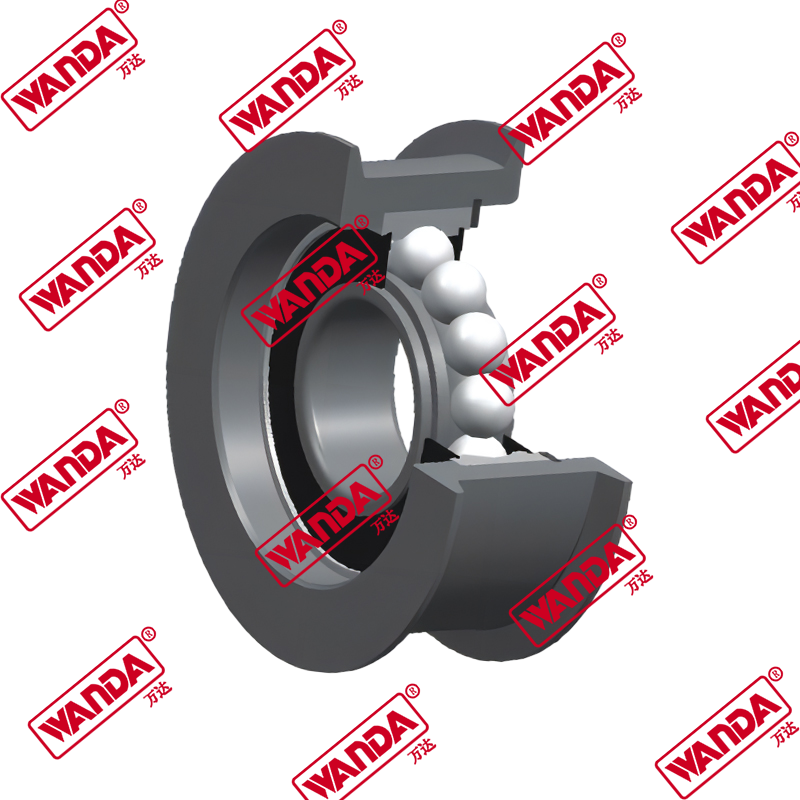

Load Capacity and Tensile Strength Ratings

One of the most critical specifications for any roller wheel chain is its load-bearing capability. This is not a single number but a combination of ratings that define the chain's limits under different conditions. The ultimate tensile strength (UTS) is the maximum load the chain can withstand in a single pull before breaking—a vital safety indicator. However, the more practical metric is the working load limit (WLL) or the maximum recommended load for continuous, safe operation, which is significantly lower than the UTS to incorporate a safety factor (often 4:1 to 8:1). For dynamic applications, fatigue strength—the ability to withstand repeated loading and unloading—is paramount. A chain might have a high UTS but poor fatigue resistance if the material or design is flawed. When selecting a chain, you must consider both the static and dynamic loads it will encounter, including shock loads from starts, stops, or uneven product flow. Ignoring these ratings is a primary cause of chain drive failure analysis and costly unplanned downtime.

- Ultimate Tensile Strength (UTS): The absolute breaking point. Always ensure the UTS far exceeds any potential peak load in your system.

- Working Load Limit (WLL): The safe operating load. Never exceed the WLL during normal operation.

- Fatigue Strength: Critical for applications with constant motion and load cycles. Influenced by material quality and design of the link plates.

- Safety Factor: The ratio between UTS and WLL. A higher safety factor (e.g., 8:1) is used for applications with high shock loads or uncertain conditions.

| Chain Type (General Example) | Typical Ultimate Tensile Strength Range | Key Application Consideration |

| Standard Series Roller Chain | Moderate to High | General power transmission, consistent loads. |

| Heavy-Duty Roller Chain | Very High | High-load, low-speed applications like conveyors. |

| Stainless Steel Roller Chain | Moderate (Corrosion Focus) | Environments where corrosion resistance is more critical than maximum load. |

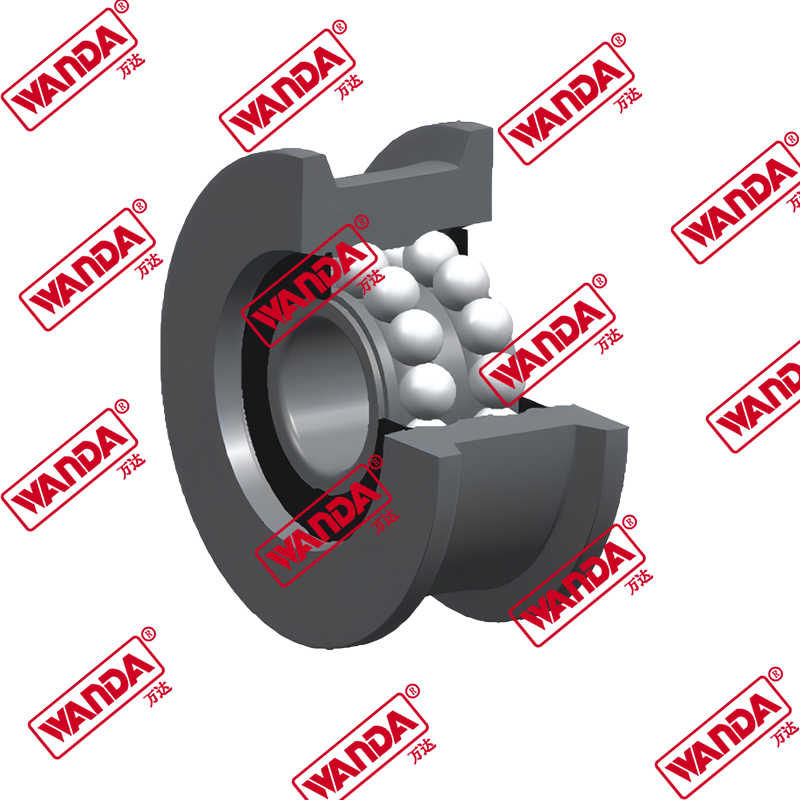

Wear Resistance and Lubrication Requirements

Wear is the natural enemy of all mechanical components, and roller wheel chains are no exception. The pivotal points—where pins rotate inside bushings and rollers contact sprockets—are constant wear zones. High-quality chains combat wear through superior materials, heat treatment, and design. The hardness of the pin and bushing surfaces is crucial; they must be hard enough to resist abrasion but also compatible to prevent galling (adhesive wear). Precisely controlled clearances between these parts allow for the formation and retention of a lubricant film, which is the most effective barrier against wear. Therefore, the chain lubrication best practices are not an afterthought but an integral part of the chain's performance specification. Some chains come pre-lubricated with special grease, while others require a specific lubrication regimen. Understanding the lubrication requirements, whether manual, drip, oil bath, or spray, is essential for achieving the chain's published service life.

- Hardened Components: Pins and bushings are typically case-hardened to a Rockwell hardness (e.g., HRC 45-60) to resist wear from friction and particulate matter.

- Internal Clearance: Optimized clearance allows lubricant to penetrate the critical pin/bushing interface, reducing metal-on-metal contact.

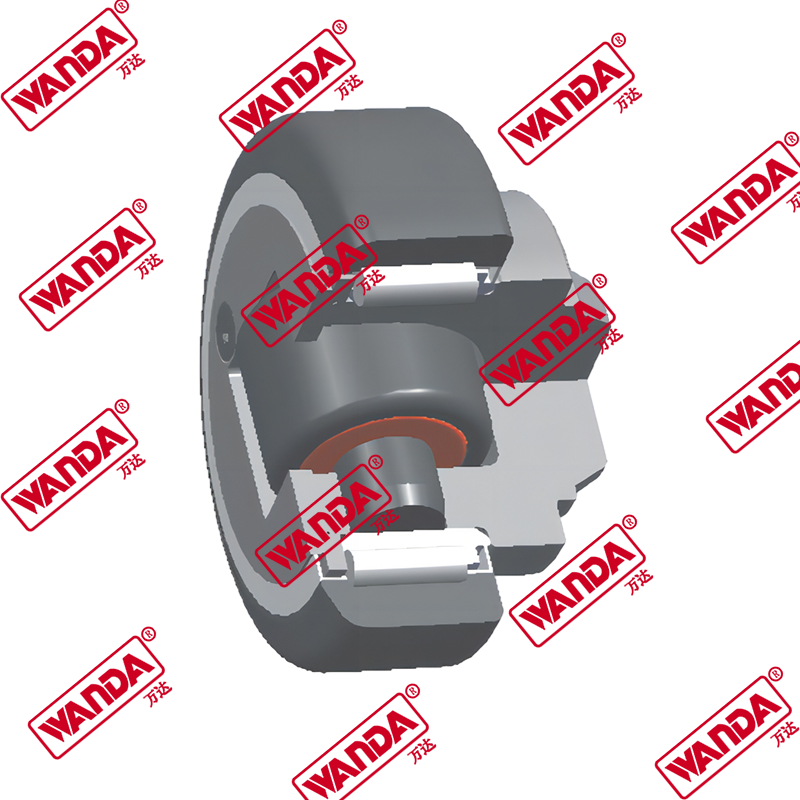

- Sealed Chains: Chains with O-rings or X-rings retain lubricant inside the pin/bushing area and exclude contaminants, dramatically extending lubrication intervals and life.

- Lubricant Types: Use oils or greases specifically designed for chains, with appropriate viscosity for operating speed and temperature.

Comparing Wear Resistance Features

The battle against wear is fought on multiple fronts. A chain's longevity in abrasive or high-cycle applications depends on a combination of its inherent properties and maintenance. Here is a comparison of key features that contribute to wear resistance.

| Feature | Standard Chain | High-Wear-Resistance Chain |

| Pin/Bushing Hardness | Standard case hardening | Deep case hardening or specialized hardening process |

| Lubrication Retention | Open design, requires frequent re-lubrication | Integrated seals (O-rings/X-rings) |

| Surface Treatment | Plain finish or basic plating | Premium coatings (e.g., DLC, advanced nitride treatments) |

| Ideal Application | Clean, low-speed, well-lubricated environments | High-speed, dirty, abrasive, or poorly lubricated environments |

Corrosion Resistance for Harsh Environments

Operating in wet, humid, or chemically aggressive environments presents a unique challenge for roller wheel chains. Standard carbon steel chains will rust quickly, leading to increased friction, accelerated wear, and eventual failure due to pitting and section loss. For these applications, corrosion resistance becomes a primary selection criterion. The most common solution is stainless steel chains, typically made from 300-series (e.g., 304, 316) alloys, which offer excellent resistance to water and many chemicals. However, stainless steel has a lower tensile strength than some alloy steels and is more susceptible to galling. Other options include chains made from nickel-plated steel, which offers a good compromise, or specialty polymers for extremely corrosive or clean-room environments. When considering corrosion resistant conveyor chains, it's vital to match the chain material to the specific contaminants (saltwater, acids, alkalis, food products) it will encounter to avoid unexpected degradation.

- Stainless Steel (300 Series): Excellent all-around corrosion resistance. Type 316 offers better resistance to chlorides (e.g., salt) than Type 304.

- Plated Finishes: Nickel or zinc plating provides a sacrificial barrier. Nickle offers better corrosion resistance than zinc but is more expensive.

- Polymer Components: Chains with polymer rollers or links are inert to many chemicals and are also lightweight and quiet.

- Operating Considerations: Even stainless steel can fail through chloride stress corrosion cracking or galvanic corrosion if paired with dissimilar metals.

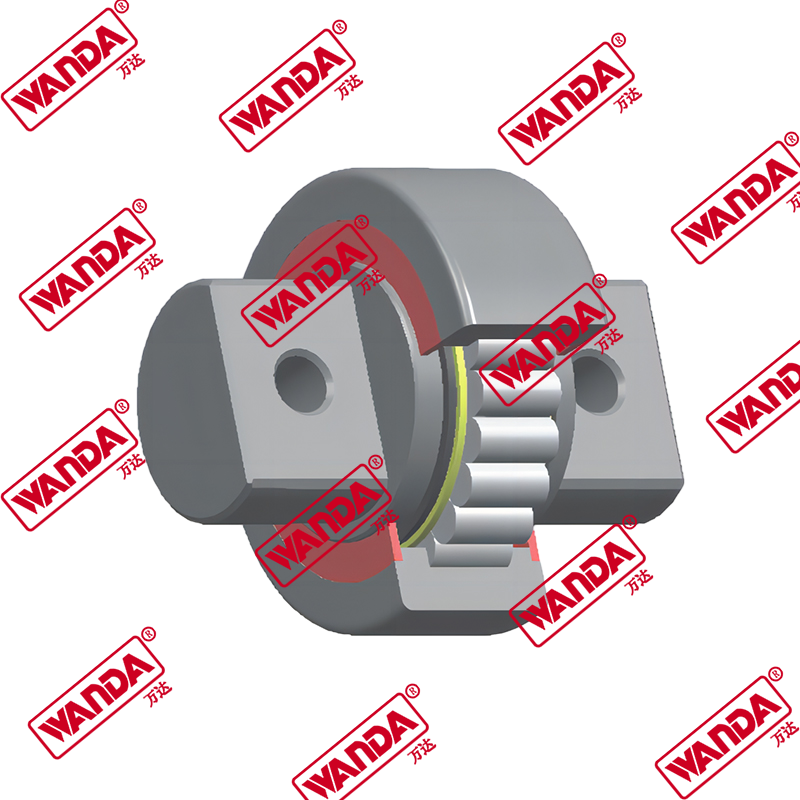

Attachment Compatibility and Customization Options

Beyond transmitting power or motion, roller wheel chains are often the backbone of material handling systems, requiring them to carry, push, or support products. This is made possible through attachments—special link plates or pins designed to hold fixtures, flights, or pins. The compatibility and strength of these attachments are crucial features. High-quality chains offer a range of standardized attachment types (A through Z, according to ANSI standards) or can be customized. Key considerations include the attachment's position (on the link plate), its material and heat treatment (which should match the chain's quality), and its load rating. Proper selection ensures the attachment won't become the weak link. Furthermore, understanding roller chain attachment types guide helps in designing efficient systems for specific tasks, such as elevating, diverting, or accumulating products on a conveyor line.

- Standardized Attachments: Types like A (on one side of the link), B (on both sides), and others (C, D, etc.) allow for the mounting of various hardware.

- Material Integrity: Attachments should be made from the same grade of material as the chain and undergo similar heat treatment.

- Custom Machining: For unique applications, chains can be manufactured with custom-fabricated attachments, holes, or special pitches.

- Load Direction: Ensure the attachment is rated for the direction of force (e.g., tension, shear) it will experience in your application.

FAQ

What is the difference between a standard roller chain and a heavy-duty roller wheel chain?

The primary differences lie in construction, material, and intended use. A standard roller chain is designed for general power transmission at moderate loads and speeds. A heavy-duty roller wheel chain is engineered for higher stress applications, often found in conveyor systems. Key distinctions include thicker link plates, larger-diameter pins and bushings made from higher-grade alloy steel, more robust heat treatment, and sometimes larger rollers. These features collectively increase the ultimate tensile strength, fatigue strength, and wear resistance, allowing the heavy-duty chain to handle greater shock loads, higher continuous loads, and longer operational life in demanding conditions. Selecting the correct type is fundamental to chain drive failure analysis, as using a standard chain in a heavy-duty application is a common root cause of premature breakage.

How often should I lubricate my industrial roller chain, and what is the best method?

Lubrication frequency is not one-size-fits-all; it depends on chain type, operating speed, temperature, and environmental conditions. For open (non-sealed) standard chains, re-lubrication might be required every 8 hours of operation in harsh conditions or every 40-80 hours in clean, moderate environments. Sealed (O-ring/X-ring) chains have internal lubricant sealed in and may only require external lubrication to protect exposed surfaces. The best method involves applying the right lubricant directly to the pin/bushing interface while the chain is moving slowly. Chain lubrication best practices recommend using a gear oil or chain-specific grease with appropriate viscosity. Methods include manual brushing, drip feeders, oil baths (for low speeds), or spray systems. The goal is to maintain a thin film of clean lubricant between all moving internal surfaces to minimize wear and prevent rust.

Can I use a stainless steel roller chain for high-load applications?

Stainless steel chains, particularly those made from common grades like 304 or 316, have lower tensile strength compared to high-quality through-hardened carbon or alloy steel chains. While they offer outstanding corrosion resistant conveyor chains properties, they are typically not the first choice for the absolute highest load applications. Their yield strength is lower, making them more prone to elongation under heavy tension. However, for many demanding applications in food processing, chemical plants, or marine environments where corrosion is the primary concern, stainless steel chains are perfectly capable and are manufactured in heavy-duty designs with larger components to compensate for the material's lower strength. The key is to consult the manufacturer's load ratings specifically for the stainless steel chain series you are considering.

What are the signs that my roller wheel chain needs to be replaced?

Proactive replacement is cheaper than catastrophic failure. Key signs include:

- Elongation (Stretch): Measure the chain's pitch over several links. Elongation exceeding 3% often indicates significant wear at the pin/bushing interface and requires replacement to prevent poor meshing with sprockets.

- Visible Wear: Look for worn, hooked, or cracked link plates, grooved or heavily polished rollers, and rust pitting that compromises material integrity.

- Poor Operation: The chain may run noisily, vibrate, ride up on sprocket teeth, or exhibit stiff links that don't flex freely.

- Corrosion Damage: Severe rust that causes flaking or a noticeable reduction in link plate thickness is a critical failure point.

Regular inspection as part of a roller chain maintenance schedule is essential to catch these signs early.

How do I select the correct roller chain attachment for my conveyor system?

Selecting the right attachment requires a systematic approach. First, clearly define the function: is it to push, carry, suspend, or divert? Next, identify the force (load) the attachment will experience and its direction. Then, consult a roller chain attachment types guide to match your needs with a standard type (e.g., Type A for a single-sided flange). Key parameters include the attachment's height, thickness, and hole size. Ensure the chain's tensile strength is rated for the combined load of the chain itself and the force on the attachment. For non-standard needs, work with a manufacturer or supplier who can provide custom-machined attachments. Always verify that the chosen attachment does not interfere with the chain's path, sprockets, or guides in your system layout.