Understanding the Role of Forklift Mast Guide Bearings

Forklift mast guide bearings play a crucial role in the smooth operation of forklifts by reducing friction between moving parts. These specialized bearings ensure the mast assembly moves vertically with minimal resistance, allowing for efficient lifting and lowering of loads. Without properly functioning guide bearings, forklifts would experience increased wear, reduced precision in load handling, and potentially dangerous operational conditions.

How Mast Guide Bearings Work in Forklift Systems

The primary function of forklift mast guide bearings is to maintain proper alignment between the mast channels while allowing smooth vertical movement. They typically consist of durable materials like hardened steel or composite polymers designed to withstand heavy loads and constant friction. The bearings are strategically placed at contact points between the mast's inner and outer channels, serving as both guides and friction reducers.

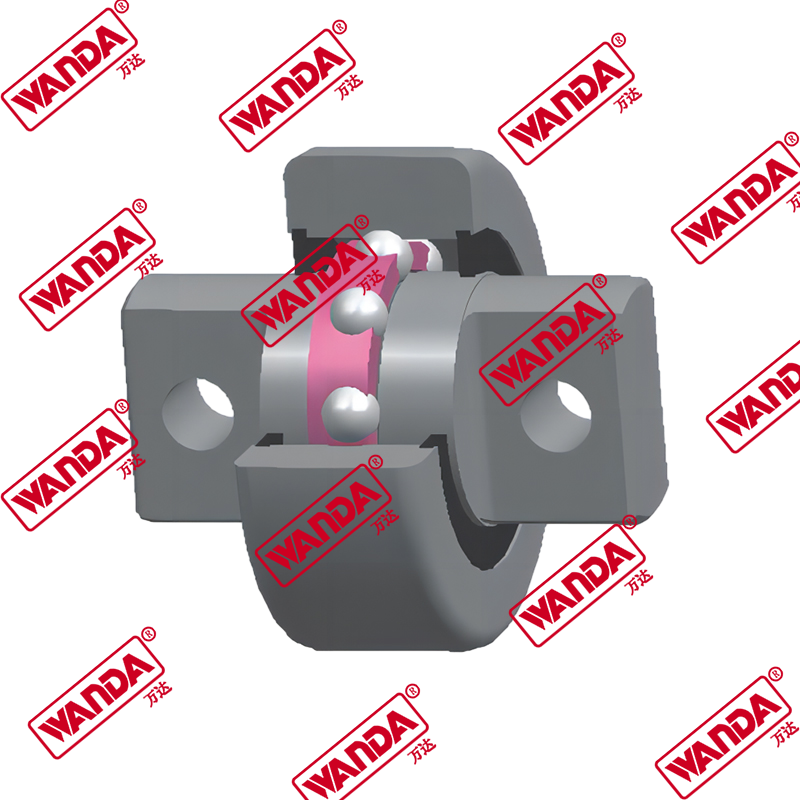

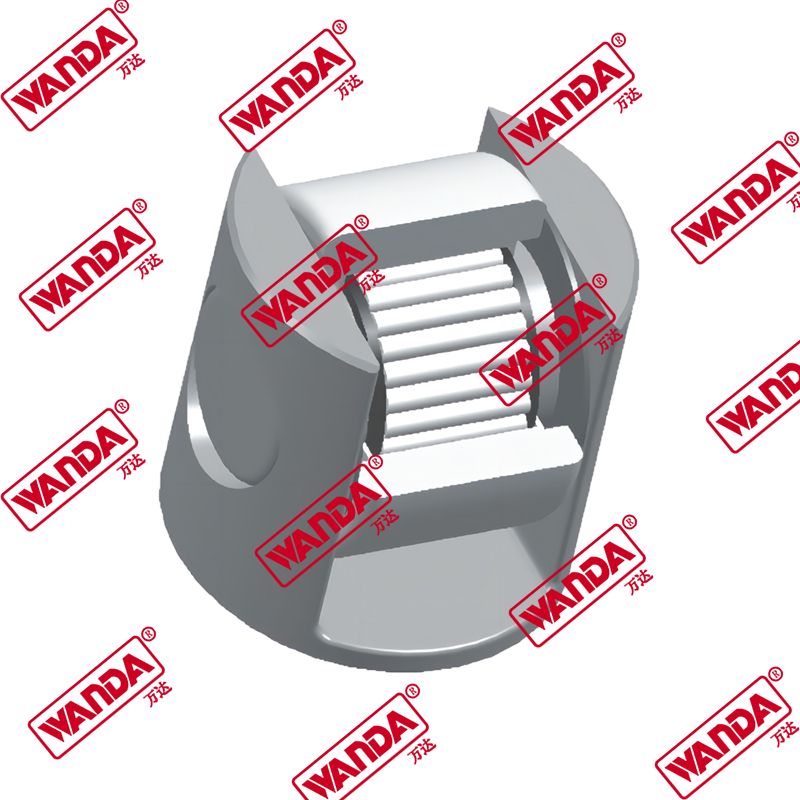

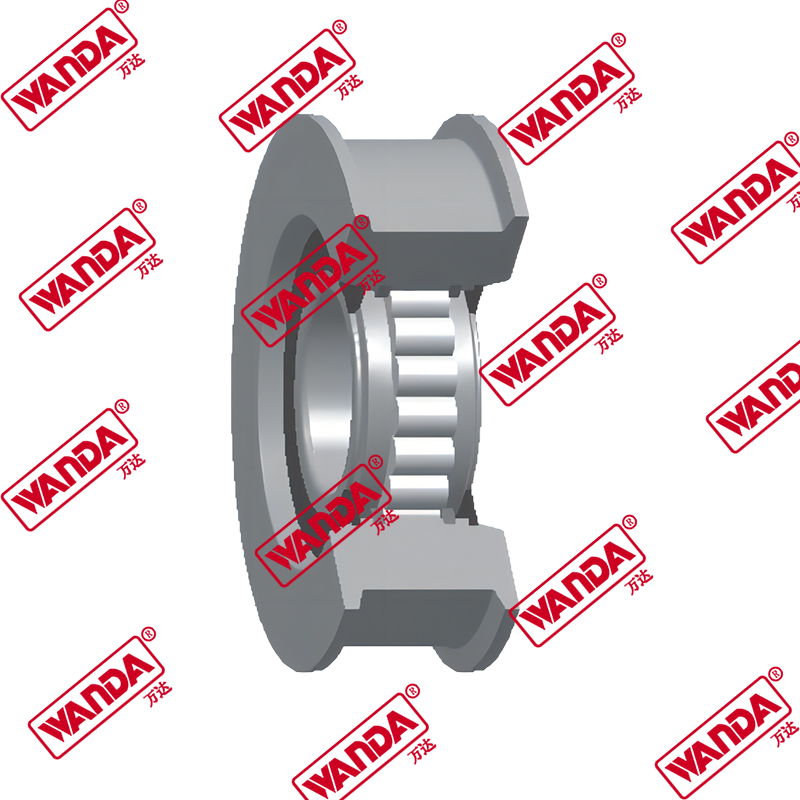

Common Types of Forklift Mast Bearings

- Roller bearings: Cylindrical rollers that provide excellent load capacity

- Ball bearings: Use spherical balls for reduced friction in lighter applications

- Composite bearings: Made from self-lubricating materials requiring less maintenance

- Needle bearings: Thin rollers ideal for applications with limited space

How to Replace Forklift Mast Guide Bearings Properly

Replacing worn or damaged mast guide bearings is essential for maintaining forklift performance and safety. The process requires careful attention to detail and proper tools to ensure the new bearings are installed correctly and function as intended.

Step-by-Step Replacement Process

- Secure the forklift on level ground with the mast fully lowered

- Remove any hydraulic lines or electrical connections that might interfere

- Support the mast assembly properly before disassembly

- Remove the old bearings, noting their orientation and position

- Clean all contact surfaces thoroughly before installing new bearings

- Install new bearings using proper alignment techniques

- Reassemble the mast components and test operation

Tools Required for Bearing Replacement

| Tool | Purpose |

|---|---|

| Bearing puller | Removing old bearings without damage |

| Hydraulic jack | Supporting mast components during work |

| Torque wrench | Proper tightening of fasteners |

| Cleaning solvents | Preparing surfaces for new bearings |

| Alignment tools | Ensuring proper bearing positioning |

Signs of Worn Forklift Mast Bearings You Shouldn't Ignore

Recognizing the symptoms of failing mast guide bearings can prevent more serious damage to your forklift and potential safety hazards. Regular inspection and early detection of bearing wear can save significant repair costs and downtime.

Common Symptoms of Bearing Failure

- Unusual noises during mast operation (grinding, squeaking)

- Rough or jerky movement when raising/lowering loads

- Visible wear or damage to bearing surfaces

- Excessive play or movement in the mast assembly

- Uneven wear patterns on mast channels

Comparing Normal vs. Worn Bearing Performance

| Characteristic | Normal Bearings | Worn Bearings |

|---|---|---|

| Mast Movement | Smooth and consistent | Jerky or hesitant |

| Noise Level | Minimal operational sound | Grinding or squeaking |

| Load Handling | Stable at all heights | Potential sway or instability |

| Wear Patterns | Even across surfaces | Uneven or excessive wear |

Best Lubricants for Forklift Mast Guide Bearings and Maintenance Tips

Proper lubrication is critical for extending the life of mast guide bearings and ensuring optimal performance. The right lubricant reduces friction, prevents corrosion, and helps dissipate heat generated during operation.

Recommended Lubricant Types

- High-quality lithium-based grease for most standard applications

- Molybdenum disulfide grease for heavy-load conditions

- Synthetic lubricants for extreme temperature operations

- Dry film lubricants for environments where grease attracts contaminants

Lubrication Schedule and Techniques

The frequency of lubrication depends on several factors including usage intensity, environmental conditions, and manufacturer recommendations. As a general guideline:

- Heavy-use forklifts: Lubricate every 50-100 operating hours

- Moderate-use equipment: Every 200-250 operating hours

- Light-use machines: At least every 3 months

Forklift Mast Bearing Failure Causes and Prevention Strategies

Understanding why mast guide bearings fail can help operators and maintenance personnel implement effective prevention measures. Most bearing failures result from identifiable and preventable causes.

Primary Causes of Premature Bearing Failure

- Contamination from dirt, debris, or moisture

- Improper lubrication (wrong type or insufficient amount)

- Misalignment during installation or from mast damage

- Overloading beyond rated capacity

- Normal wear over extended use

Preventive Maintenance Measures

| Problem | Prevention Strategy |

|---|---|

| Contamination | Regular cleaning and use of protective seals |

| Improper Lubrication | Follow manufacturer specs and schedules |

| Misalignment | Proper installation and regular inspections |

| Overloading | Operate within rated capacity limits |

| Normal Wear | Timely replacement based on service life |

Forklift Mast Guide Bearing Specifications and Selection Criteria

Choosing the right mast guide bearings for your forklift requires understanding various specifications and how they relate to your specific operating conditions. Proper bearing selection ensures optimal performance and longevity.

Key Specifications to Consider

- Load capacity ratings (static and dynamic)

- Material composition (steel, bronze, composite)

- Dimensions (ID, OD, width)

- Temperature range compatibility

- Corrosion resistance requirements

Matching Bearings to Forklift Types

| Forklift Type | Recommended Bearing Characteristics |

|---|---|

| Warehouse Electric | Lightweight, low-maintenance composites |

| Heavy-duty IC | High-capacity steel rollers |

| High-reach | Precision bearings with minimal play |

| Rough terrain | Sealed bearings with impact resistance |