Forklift Combined Roller Bearings play a critical role in the performance and longevity of forklifts. These bearings are specifically designed to handle high loads, reduce friction, and provide smooth movement for various forklift components. Choosing the right bearing not only enhances operational efficiency but also minimizes maintenance costs and downtime. In industrial environments, where forklifts are used extensively for lifting and transporting materials, the quality of bearings can directly impact the safety and productivity of operations. By understanding the essential features and differences among bearings, operators and maintenance teams can make informed decisions to maximize equipment performance.

- Importance of high-quality bearings in forklift operations

- Impact on load handling, stability, and safety

- Brief overview of long-tail keyword applications

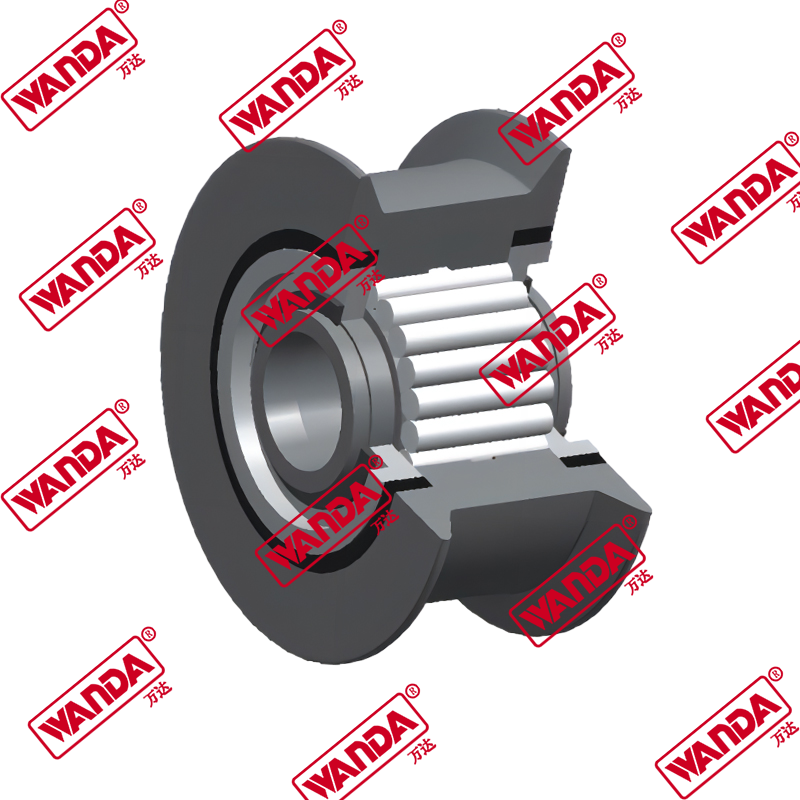

1. Forklift Combined Roller Bearing for Mast Guide

The mast guide is a critical part of a forklift’s lifting mechanism. Using a Forklift Combined Roller Bearing for Mast Guide ensures precise alignment and smooth vertical movement of the forks. These bearings reduce wear and tear on the mast rails and improve load handling accuracy. With proper selection and maintenance, mast guide bearings can extend the life of the forklift’s lifting system while enhancing operator safety and comfort. Their design allows for even load distribution, minimizing stress on individual components.

- Key Functions in Mast Guide Systems

- Reduces friction between mast rails and carriage

- Maintains alignment under heavy loads

- Enhances lifting precision and smoothness

- Advantages of Using Specialized Mast Guide Bearings

- Extended equipment life due to reduced wear

- Improved safety and load control

- Minimized maintenance requirements

- Tips for Installation and Maintenance

- Regular lubrication and inspection

- Ensure correct alignment during installation

- Monitor for signs of excessive wear or noise

-

Feature Benefit High load capacity Supports heavy lifting without deformation Low friction design Reduces energy consumption and wear Precision machining Ensures smooth vertical mast movement

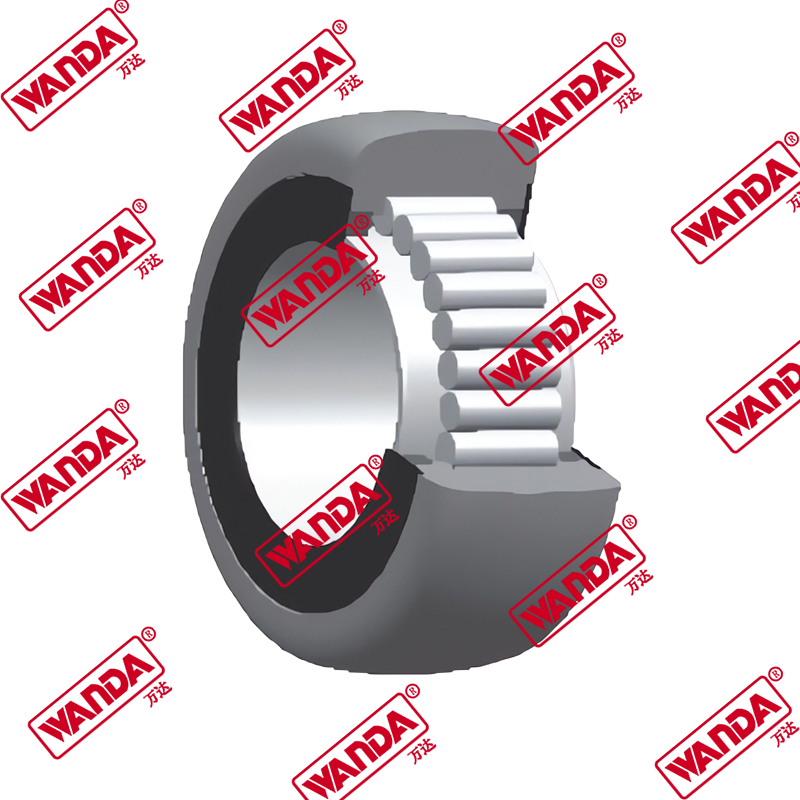

2. Heavy-Duty Combined Roller Bearing for Forklifts

For forklifts operating in industrial and heavy-duty environments, Heavy-Duty Combined Roller Bearings for Forklifts are essential. They are engineered to handle higher loads and resist deformation under stress. Their robust design makes them ideal for continuous operations in warehouses, manufacturing plants, and outdoor logistics settings. Heavy-duty bearings also contribute to minimizing operational downtime and maintenance costs by offering greater durability and reliability under challenging conditions.

- Suitable Applications for Heavy-Duty Bearings

- High-capacity forklifts in warehouses and logistics centers

- Outdoor forklifts handling heavy pallets and containers

- Continuous operation in manufacturing facilities

- Load Capacity and Durability Considerations

- Rated load capacity ensures safe lifting

- High durability materials reduce deformation and wear

- Designed to withstand vibrations and shocks

- Selecting Bearings for Industrial Environments

- Choose corrosion-resistant materials for outdoor use

- Verify lubrication requirements for continuous operation

- Check compatibility with specific forklift models

-

Feature Benefit Heavy-duty construction Handles high loads safely Shock resistance Reduces downtime from impact damage Corrosion resistance Extends bearing life in harsh environments

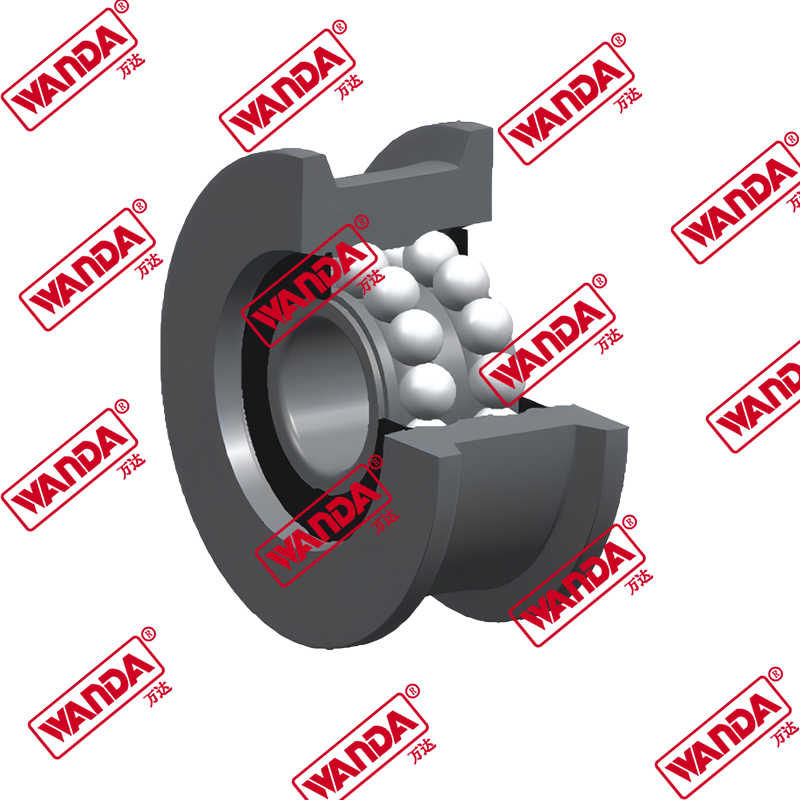

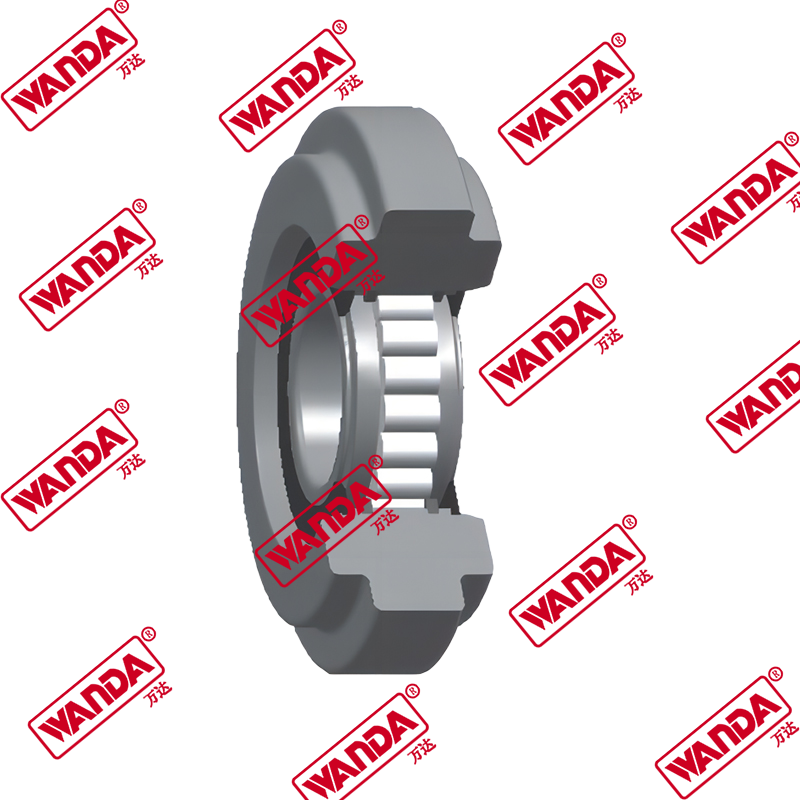

3. Combined Roller Bearing for Forklift Carriage System

The carriage system of a forklift is responsible for supporting and moving the forks laterally. Using a Combined Roller Bearing for Forklift Carriage System ensures smooth side-to-side motion, precise alignment, and even load distribution. These bearings reduce friction between the carriage and the mast, improving efficiency and preventing premature wear. They are particularly valuable in applications that require frequent lifting and tilting motions, where consistent performance is critical.

- Role in Forklift Carriage Stability

- Maintains proper fork alignment during lifting

- Prevents tilting and uneven load distribution

- Improves safety for operators and cargo

- Materials and Construction Features

- High-grade steel for load-bearing components

- Precision-machined rollers for smooth operation

- Sealed designs to prevent contamination

- Preventing Common Wear and Tear

- Regular inspection for cracks or deformation

- Ensure proper lubrication to reduce friction

- Replace worn bearings promptly to prevent cascading damage

-

Feature Benefit Sealed roller design Prevents debris contamination High precision rollers Ensures smooth carriage movement Durable steel construction Supports long-term operation without failure

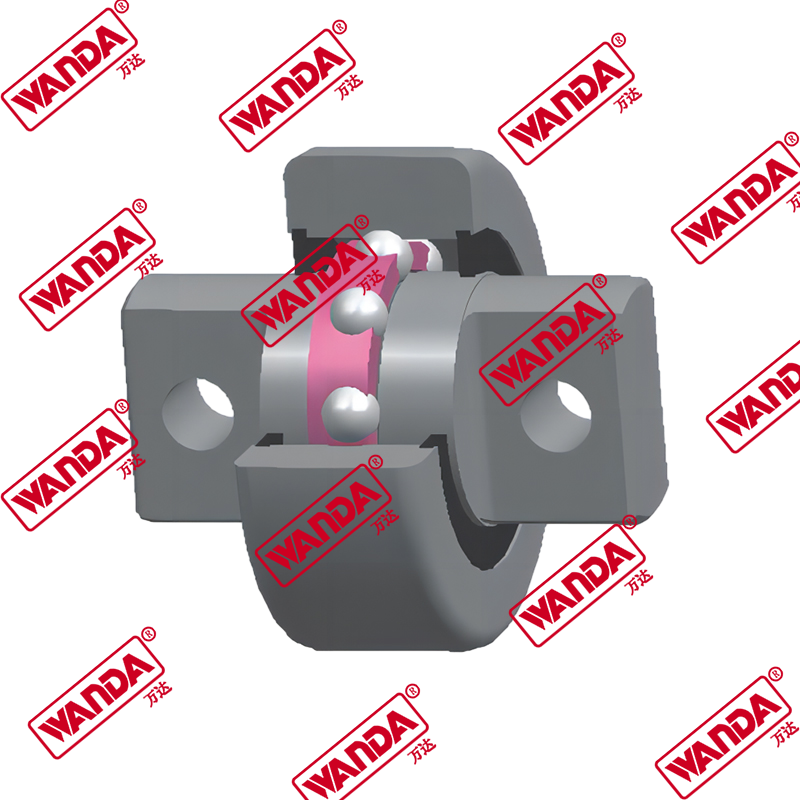

4. Compact Combined Roller Bearing for Forklift Applications

In environments where space is limited, a Compact Combined Roller Bearing for Forklift Applications provides a practical solution. Its smaller form factor allows installation in tight areas without sacrificing load capacity or performance. Compact bearings are often used in forklifts designed for narrow aisles or small warehouses. Despite their size, these bearings are engineered for durability and can handle continuous operational demands while reducing friction and improving efficiency.

- Benefits of Compact Design in Tight Spaces

- Fits into restricted spaces without compromising function

- Facilitates maneuverability in narrow aisles

- Maintains lifting and carriage stability

- Lightweight vs. Heavy-Duty Tradeoffs

- Compact design reduces weight for easier installation

- Must balance between size and load-bearing capability

- Optimized for medium-duty applications

- Optimizing Performance in Confined Areas

- Regular inspection for alignment issues

- Lubrication to minimize friction in small gaps

- Choose materials that resist wear despite reduced size

-

Feature Benefit Compact form factor Easy installation in narrow areas Lightweight construction Reduces forklift overall weight Durable material Ensures long-term performance in tight spaces

5. Durable Combined Roller Bearing for Forklift Vertical Mast

The vertical mast of a forklift endures constant load and movement. Using a Durable Combined Roller Bearing for Forklift Vertical Mast ensures stability, reduces wear, and maintains performance over time. These bearings are designed to handle vertical lifting stresses, shock loads, and frequent operational cycles. Investing in durable bearings helps prevent unexpected breakdowns, improves safety, and extends the overall lifespan of the forklift.

- Importance of Durability in Vertical Mast Operations

- Supports continuous lifting without deformation

- Reduces maintenance frequency and cost

- Enhances operator confidence and safety

- Key Features to Ensure Long-Lasting Performance

- High load-bearing capacity

- Resistance to wear and corrosion

- Optimized roller design for smooth vertical motion

- Maintenance Tips to Extend Bearing Life

- Regular inspection for lubrication levels

- Immediate replacement of worn components

- Use high-quality lubricants compatible with bearing materials

-

Feature Benefit High durability materials Extends vertical mast lifespan Optimized roller design Ensures smooth lifting Wear-resistant surface Reduces maintenance and downtime

FAQ

What are the key signs that a forklift combined roller bearing needs replacement?

Signs that a Forklift Combined Roller Bearing needs replacement include unusual noises, vibration during operation, visible wear or deformation, and inconsistent load handling. Bearings in mast guides, carriage systems, and vertical masts are prone to wear from heavy use, high loads, and environmental exposure. Regular inspection and maintenance are critical to identify these issues early. Using high-quality, durable bearings and performing preventive maintenance can extend service life and avoid costly downtime.

How do I choose the right heavy-duty combined roller bearing for my forklift?

When selecting a Heavy-Duty Combined Roller Bearing for Forklifts, consider load capacity, operational environment, and expected service life. Bearings should be rated for the maximum weight the forklift will carry and designed to withstand shocks and vibrations. Environmental factors, such as exposure to moisture, dust, or chemicals, should influence material selection. Comparing specifications, manufacturer guidelines, and maintenance requirements ensures optimal performance and longevity.

Can compact combined roller bearings handle heavy loads efficiently?

Compact Combined Roller Bearings for Forklift Applications are designed to balance space constraints with performance. While they can handle moderate to medium loads effectively, extremely heavy loads may require heavy-duty or specialized bearings. Proper material selection, lubrication, and periodic inspection help compact bearings perform reliably in tight spaces without compromising safety or operational efficiency.

What maintenance practices ensure durability of forklift vertical mast bearings?

To maintain a Durable Combined Roller Bearing for Forklift Vertical Mast, regular lubrication, inspection for wear or deformation, and timely replacement of worn components are essential. Ensuring correct alignment during installation, using compatible lubricants, and avoiding overloads will extend bearing life. Preventive maintenance reduces downtime and keeps forklifts operating safely and efficiently.

Are combined roller bearings suitable for all forklift carriage systems?

Combined Roller Bearings for Forklift Carriage Systems are suitable for most standard carriage designs, providing smooth lateral movement and precise alignment. However, compatibility must be confirmed based on load requirements, carriage dimensions, and operational conditions. Proper selection ensures optimal performance, reduced wear, and longer bearing lifespan.