Understanding the Role of Forklift Side Rollers

Forklift side rollers are crucial components in the mast assembly of material handling equipment, ensuring smooth vertical movement of the mast channels while reducing friction and wear. These rollers guide the mast channels during lifting and lowering operations, directly impacting stability, load control, and operational safety. High-quality side rollers minimize vibration and noise, contributing to precision handling and extended equipment lifespan. Understanding their function helps operators and maintenance teams recognize early signs of wear, preventing costly downtime and repairs. This section explores the mechanics of side rollers and their significance in daily forklift operations.

How Side Rollers Enhance Mast Performance

Side rollers are engineered to withstand heavy loads and repetitive motion, which are common in industrial environments. By providing consistent contact with the mast channels, they distribute stress evenly and prevent metal-on-metal abrasion. For instance, when comparing standard rollers to premium models, the latter often feature reinforced cores and advanced sealing mechanisms. These design improvements reduce the risk of roller jamming and mast misalignment. Operators will notice smoother hydraulic movements and better control when handling palletized goods or navigating narrow aisles. Investing in robust side rollers translates to fewer operational interruptions and lower long-term maintenance costs.

Key Benefits of Optimized Side Rollers

- Reduced friction and heat generation during mast extension

- Enhanced load stability through precise channel guidance

- Extended service life for mast components and roller assemblies

- Decreased energy consumption due to efficient movement

- Improved safety by minimizing sudden mast shifts

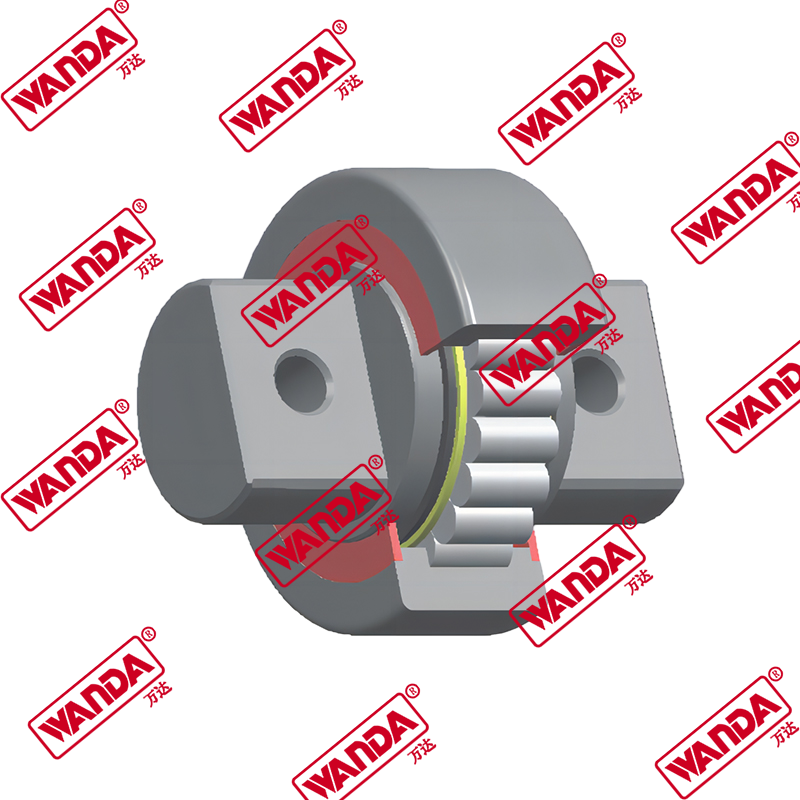

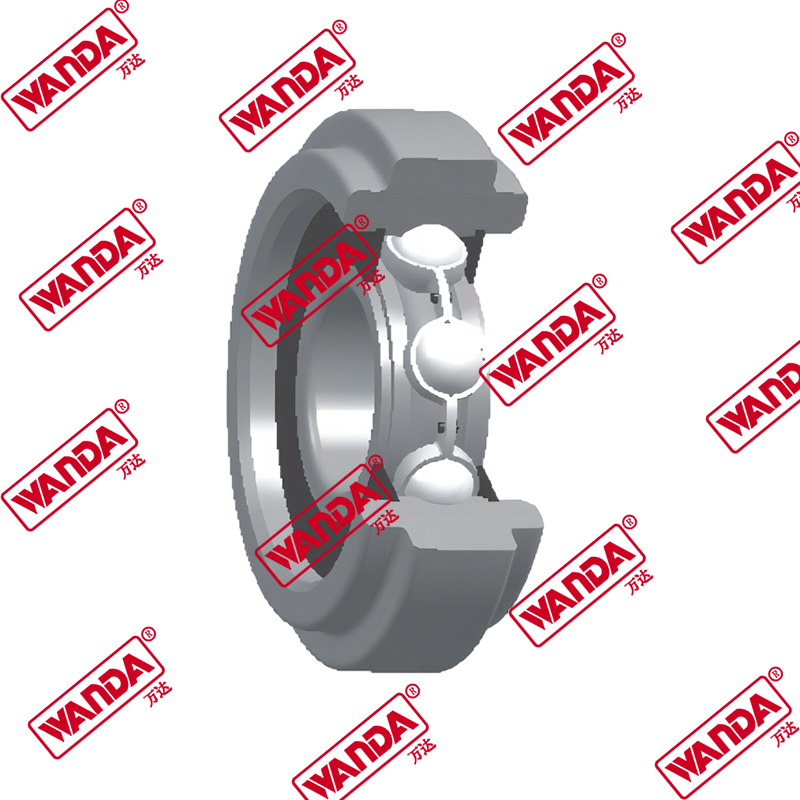

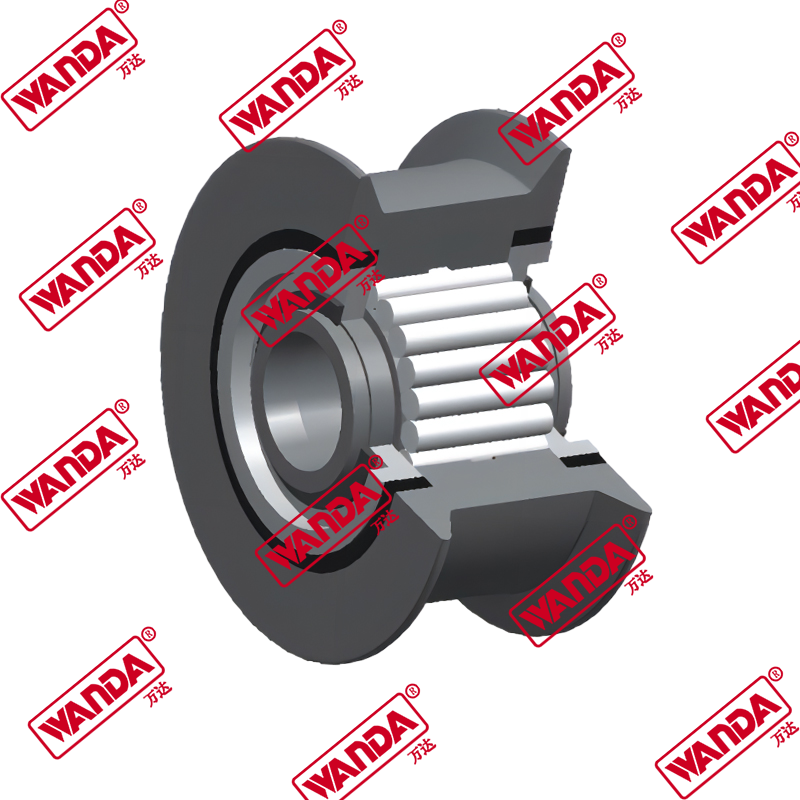

Essential Features of Durable Forklift Side Rollers

When selecting replacement parts, it's vital to prioritize durability and compatibility. High-quality forklift side rollers incorporate hardened steel or polymer composites, which resist deformation under pressure. Sealed bearings are another critical feature, as they prevent contamination from dust, moisture, and debris. Unlike basic rollers, premium variants maintain their structural integrity in extreme temperatures and high-frequency use. The following comparison highlights differences between economy and heavy-duty side rollers:

Economy-grade rollers may have simple grease fittings and minimal sealing, whereas heavy-duty options include multi-lip seals and corrosion-resistant coatings. This makes the latter ideal for demanding applications like cold storage or outdoor construction sites. Additionally, rollers with precision-machined surfaces ensure consistent contact with mast channels, reducing the likelihood of uneven wear. Facilities that prioritize equipment longevity should opt for models with these advanced features.

| Feature | Economy Rollers | Heavy-Duty Rollers |

|---|---|---|

| Material | Standard carbon steel | Case-hardened steel or polymer composites |

| Bearing Protection | Basic dust seals | Multi-lip seals with grease reservoirs |

| Load Capacity | Moderate (e.g., up to 5,000 lbs) | High (e.g., over 10,000 lbs) |

| Environmental Resistance | Limited | High (resists corrosion, moisture, and extreme temperatures) |

Common Issues and Maintenance Tips for Side Rollers

Regular inspection and maintenance are key to preventing side roller failure. Common issues include excessive play, visible cracks, and uneven wear patterns. These problems often stem from improper lubrication, overloading, or misalignment. For example, forklift side roller replacement cost can vary significantly based on the forklift model and roller quality, but proactive maintenance helps avoid unexpected expenses. Below is a structured approach to side roller upkeep:

Identifying Wear and Tear

Operators should listen for grinding noises during mast movement and check for grooves on roller surfaces. If rollers appear flattened or discolored, they may be nearing the end of their service life. Comparing worn rollers to new ones reveals how subtle changes in diameter or surface texture can affect performance. Addressing these signs early prevents cascading damage to adjacent mast components.

Lubrication and Cleaning Procedures

Using the correct lubricant is critical for reducing friction. High-temperature grease is recommended for intensive applications, while general-purpose grease suffices for standard use. Cleaning rollers with a non-abrasive solvent removes debris that accelerates wear. Establish a maintenance schedule based on operational hours to ensure consistency.

Choosing the Right Side Rollers for Your Forklift

Selecting compatible side rollers requires attention to specifications like roller diameter, bore size, and load rating. Consult the equipment manual to verify dimensions and material requirements. For instance, specifications for forklift mast rollers typically include hardness ratings (e.g., Rockwell scale) and dimensional tolerances. Purchasing rollers that meet or exceed OEM standards ensures reliable performance and avoids compatibility issues.

Factors to Consider During Selection

- Mast type (e.g., duplex, triplex, or quad)

- Operating environment (indoor, outdoor, corrosive, or clean)

- Load frequency and weight distribution

- Roller material compatibility with mast channels

- Warranty and supplier reliability

Enhancing Forklift Longevity with Proper Side Roller Care

Well-maintained side rollers contribute to the overall health of a forklift. They reduce strain on hydraulic systems, chains, and other mast components. For example, how to install forklift mast rollers involves aligning the roller brackets precisely to prevent binding. Incorrect installation can lead to premature wear or mast instability. Follow these steps for optimal results:

- Secure the mast in a lowered position to relieve tension.

- Remove retaining clips and pins from the old rollers.

- Clean the mounting areas thoroughly before installing new rollers.

- Apply lubricant to bearings and contact surfaces.

- Test mast movement without load to verify smooth operation.

Impact on Total Cost of Ownership

Proactive side roller maintenance lowers the total cost of ownership by reducing repair frequency and downtime. For instance, benefits of tapered forklift rollers include better alignment and reduced edge wear, which extends intervals between replacements. Compared to cylindrical rollers, tapered designs handle misalignment more effectively, making them suitable for older masts with slight deformities.

| Aspect | Standard Cylindrical Rollers | Tapered Rollers |

|---|---|---|

| Alignment Tolerance | Low | High |

| Edge Wear Resistance | Moderate | Superior |

| Ideal Application | New masts with precise channel gaps | Older masts or high-flexibility operations |

Advanced Solutions for Demanding Applications

In high-intensity settings like logistics hubs or manufacturing plants, specialized side rollers offer superior performance. For example, noise reduction in forklift mast rollers is achievable through polymer-coated designs that dampen vibrations. These rollers are especially valuable in noise-sensitive environments like retail warehouses or early-morning shifts. Additionally, corrosion-resistant coatings protect against chemical exposure in industries like agriculture or food processing.

Innovations in Roller Materials

Modern side rollers incorporate engineered thermoplastics and composite metals, which provide self-lubricating properties and higher impact resistance. Unlike traditional steel rollers, these materials do not require frequent re-greasing and are lighter, reducing the overall weight of the mast assembly. However, they may have lower heat tolerance, so evaluate operational conditions before switching materials.

Customization for Unique Needs

Some applications require custom-sized rollers to fit non-standard mast designs. Work with reputable suppliers who can provide tailored solutions based on technical drawings or samples. Custom rollers often involve longer lead times but ensure perfect compatibility and optimized performance.